-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing hex tap bolts (full thread) to meet the demands of various industries, including construction, automotive, machinery, and infrastructure. As a trusted hex tap bolt manufacturer, we pride ourselves on delivering high-quality, precision-engineered fasteners that are reliable, durable, and customizable to suit any project requirements. Whether you need bolts in standard sizes or custom specifications, we provide the perfect solution to help your projects succeed.

1.jpg?x-oss-process=image/resize,w_100/quality,q_100)

2.jpg?x-oss-process=image/resize,w_100/quality,q_100)

3.jpg?x-oss-process=image/resize,w_100/quality,q_100)

4.jpg?x-oss-process=image/resize,w_100/quality,q_100)

5.jpg?x-oss-process=image/resize,w_100/quality,q_100)

What Are Hex Tap Bolts (Full Thread)?

Hex tap bolts, also known as fully threaded hex bolts, are designed with threads running their entire length, allowing for a strong, secure connection. These bolts are widely used in applications where a fastener needs to be fully engaged with a nut or threaded hole. The hexagonal head ensures ease of installation with a wrench or socket, making them a go-to fastener for industrial, structural, and heavy-duty applications.

Why Choose JM Hardware® for Hex Tap Bolts?

As an experienced hex tap bolt manufacturer, we understand the critical requirements of B2B buyers. Here's why clients from around the globe trust us:

1.Wide Product Range: We offer hex tap bolts in a variety of materials, sizes, threads, and finishes to cater to different industries.

2.Custom Manufacturing: We can produce bolts in unique dimensions and materials to suit specific project requirements.

3.Uncompromising Quality: Our bolts meet or exceed international standards such as ASTM, DIN, ISO, and JIS, ensuring reliability and performance.

4.Corrosion Resistance: Our advanced coatings and surface treatments enhance durability, making our bolts suitable for harsh environments.

5.Global Delivery: With extensive logistics experience, we ensure fast and reliable delivery to clients worldwide.

Materials for Hex Tap Bolts

To meet the diverse needs of our customers, we manufacture hex tap bolts using the following materials:

-

Carbon Steel:

Ideal for general-purpose applications, offering excellent tensile strength and cost-efficiency.

-

Stainless Steel (SS304, SS316):

2. Provides superior corrosion resistance, suitable for marine, chemical, and high-humidity environments.

-

Alloy Steel:

Perfect for high-stress applications due to its enhanced strength and wear resistance.

-

Brass:

Used for electrical conductivity and corrosion resistance in sensitive applications.

-

Duplex Stainless Steel:

Combines strength and corrosion resistance, making it ideal for challenging environments like offshore and coastal projects.

-

Titanium:

Lightweight yet incredibly strong, titanium bolts are used in aerospace, defense, and medical applications.

Surface Treatments and Coatings

As a leading hex tap bolt manufacturer, we provide various surface finishes to enhance the durability and appearance of our products:

-

Hot-Dip Galvanizing:

Ideal for outdoor applications, offering excellent corrosion protection.

-

Zinc Plating:

Provides a cost-effective solution for rust resistance in mild environments.

-

Teflon Coating:

3.Offers exceptional resistance to chemicals and extreme temperatures, making it ideal for industrial use.

-

Black Oxide Coating:

4. A sleek, protective finish with moderate corrosion resistance.

-

Phosphate Coating:

Adds lubrication and basic corrosion resistance, commonly used in automotive and machinery applications.

Grades and Strengths of Hex Tap Bolts

Our hex tap bolts are manufactured to meet a range of mechanical properties, ensuring they are suitable for any application:

1.Grade 4.8, 8.8, 10.9, and 12.9 (Carbon Steel): Suitable for light to heavy-duty applications, offering varying levels of tensile strength.

2.ASTM A193 B7, B7M: Ideal for high-temperature and high-pressure environments, commonly used in the oil and gas industry.

3.Grade A2-70, A4-80 (Stainless Steel): Highly corrosion-resistant, designed for marine and chemical applications.

4.DIN 933 and DIN 931: European standards for strength and precision.

5.SAE J429 Grade 2, 5, 8: Commonly used in automotive and heavy machinery applications.

Applications of Heavy Hex Structural Bolts

Heavy hex structural bolts are essential in critical construction and infrastructure projects where strength and durability are non-negotiable. Some common applications include:

-

Construction

Used to secure structural steel, beams, and frames in buildings, bridges, and infrastructure projects.

-

Automotive

Essential in assembling engines, transmissions, and suspension systems.

-

Industrial Machinery

Perfect for connecting heavy-duty components in manufacturing equipment

-

Oil & Gas

4.High-strength bolts are used in pipelines, refineries, and offshore platforms.

-

Renewable Energy

Bolts are crucial in the assembly of wind turbines and solar mounting systems.

-

Marine Applications

Stainless steel and galvanized bolts are ideal for securing components in boats, docks, and coastal infrastructure.

-

Agriculture

Used in tractors, irrigation systems, and other farming equipment.

Quality Control and Testing

As a professional hex tap bolt manufacturer, we perform extensive testing to ensure the quality and reliability of our products:

-

Tensile Strength Testing:

Verifies the bolt's ability to withstand axial forces.

-

Hardness Testing:

Verifies the material's ability to resist deformation under stress.

-

Salt Spray Testing

Evaluates corrosion resistance for coated bolts.

-

Dimensional Inspection:

Ensures the bolts meet precise size and threading standards.

-

Impact Testing:

Assesses the bolt's performance under dynamic loading conditions.

-

Vibration Testing:

Ensures the bolt maintains its integrity in high-vibration environments, such as machinery or vehicles

Production Process for Hex Tap Bolts

Our advanced manufacturing processes ensure precision and quality at every stage:

-

Material Selection:

Premium materials are sourced to meet strength and corrosion resistance requirements.

-

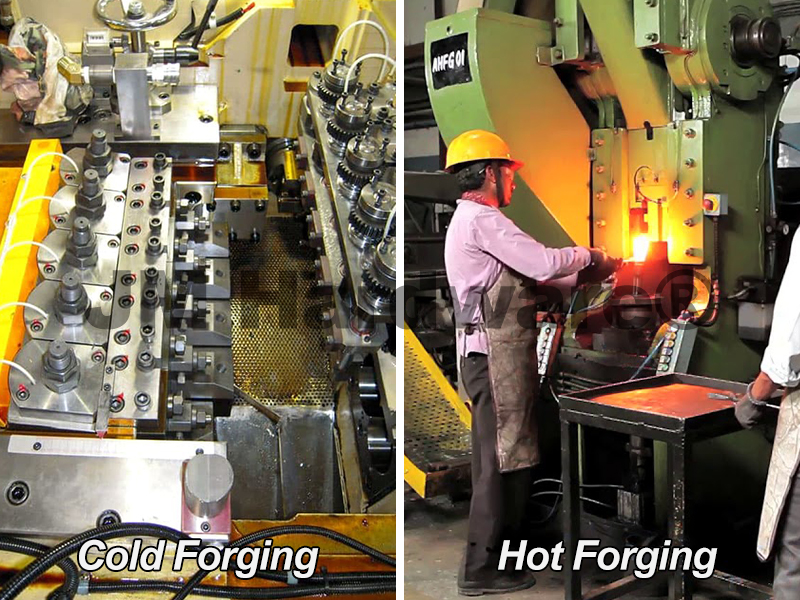

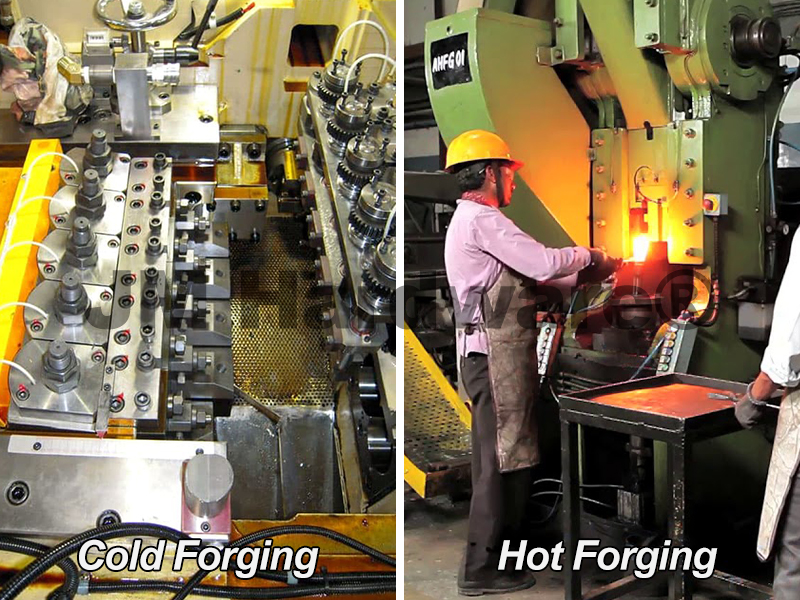

Cold or Hot Forging:

Bolts are forged into the desired shape, ensuring superior strength and accuracy.

-

Thread Rolling:

Threads are rolled (not cut) to enhance the strength and durability of the bolts.

-

Heat Treatment:

Applied to improve tensile strength, hardness, and wear resistance.

-

Surface Treatment:

5. Coatings and treatments are applied to enhance corrosion resistance and extend lifespan.

-

Quality Inspection:

Each bolt undergoes rigorous testing to ensure it meets dimensional, mechanical, and performance specifications.

Why Choose JM Hardware® as Your Heavy Hex Structural Bolt Manufacturer?

1.Unmatched Expertise: Years of experience in fastener manufacturing ensures the highest quality products.

2.Custom Solutions: We provide tailored fasteners to meet your unique requirements.

3.Global Standards Compliance: Our bolts adhere to international standards like ASTM, DIN, ISO, and SAE.

4.State-of-the-Art Facility: Advanced equipment and precision processes guarantee consistent quality.

5.Timely Delivery: We ensure fast shipping and reliable delivery to any location worldwide.

6.Competitive Pricing: High-quality products at affordable rates without compromising on performance.

Why Choose JM Hardware® as Your Hex Tap Bolt Manufacturer?

Looking for a reliable hex tap bolt manufacturer? At JM Hardware®, we deliver precision-engineered fasteners that exceed expectations. Whether you need standard or custom bolts, our team is here to meet your requirements with efficiency and expertise. Contact us today to discuss your project or request a quote. JM Hardware® – Your Partner for Reliable Fastening Solutions.

5.jpg)