-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a leading Concrete Bolt Manufacturer specializing in high-quality fasteners designed for the concrete construction industry. Concrete bolts are critical components used in securing and anchoring concrete structures, ensuring stability, strength, and safety. Our concrete bolts are engineered to meet the most demanding industry standards, offering unparalleled performance in various construction applications. With extensive experience in manufacturing, strict quality control processes, and a focus on customer satisfaction, we are your trusted partner for all concrete bolt needs.

Comprehensive Range of Concrete Bolts for Every Project

As a Concrete Bolt Manufacturer, we offer an extensive range of concrete bolts to suit a variety of construction applications. These include:

-

Expansion Bolts:

Ideal for securing structural components to concrete, offering strong holding power.

-

Wedge Anchors:

Designed for high-strength fastening in concrete, ensuring durability in both indoor and outdoor settings.

-

Sleeve Anchors:

Versatile fasteners for use in concrete, brick, or block, providing secure attachment in various conditions.

-

Concrete Screws:

Self-tapping screws that provide easy installation and secure fastening in pre-drilled concrete holes.

-

Hammer Drive Anchors:

Used for light-duty applications, hammer drive anchors are quick and easy to install in concrete.

-

Drop-In Anchors:

Perfect for applications requiring flush mountings in concrete, commonly used for mounting fixtures and heavy equipment.

-

Concrete Insert Bolts:

Designed for use in precast concrete, providing reliable attachment points in structures like walls and slabs.

-

Heavy-Duty Concrete Anchors:

Built for high-load applications, ensuring superior strength and long-term performance.

Our product range is designed to meet the needs of diverse construction projects, from residential and commercial buildings to large infrastructure projects.

Materials for Concrete Bolts

The materials used for concrete bolts are crucial to their performance and durability, especially in harsh construction environments. JM Hardware® manufactures concrete bolts using the following materials:

-

Carbon Steel:

Used for general applications, offering excellent strength at a cost-effective price point.

-

Stainless Steel (SS304, SS316):

Provides exceptional resistance to corrosion, ideal for outdoor, marine, and high-humidity environments.

-

Alloy Steel:

Used in high-stress applications, offering superior strength for anchoring heavy equipment or structural components.

-

Galvanized Steel:

Perfect for outdoor construction projects where corrosion resistance is necessary, without compromising on strength.

-

Brass:

Used for specialized applications that require resistance to corrosion and better conductivity.

-

Boron Steel:

Known for its high tensile strength and wear resistance, often used for heavy-duty fastening in concrete.

Each material is carefully selected to ensure optimal performance for specific applications in concrete construction.

Surface Finishes and Coatings for Concrete Bolts

To enhance the longevity and performance of our concrete bolts, we offer a range of surface finishes and coatings that provide resistance against corrosion, wear, and environmental factors:

-

Zinc Plating:

Commonly used for fasteners exposed to moderate environmental conditions, offering corrosion resistance at a lower cost.

-

Hot-Dip Galvanizing:

Provides robust corrosion resistance, perfect for outdoor and industrial applications in concrete.

-

Black Oxide Coating:

Provides a sleek black finish with moderate corrosion resistance, ideal for indoor applications or low-humidity environments.

-

Epoxy Coating:

Offers advanced protection in aggressive chemical environments or marine projects.

-

Passivation(for stainless steel):

A surface treatment applied to stainless steel bolts that enhances their natural corrosion resistance, extending their lifespan.

-

Teflon Coating:(for stainless steel):

Offers superior protection against harsh chemicals and extreme conditions, ideal for industrial construction.

These finishes ensure that our concrete bolts can withstand the demanding conditions typically encountered in construction environments.

Grades and Standards for Concrete Bolts

As a Concrete Bolt Manufacturer, we ensure that all our bolts meet the highest standards of strength and durability. Our concrete bolts are available in various grades, designed to suit different construction applications:

-

Grade 5 (Carbon Steel)

Standard-grade bolts for light to medium-duty applications.

-

Grade 8(Carbon Steel)

High-strength bolts designed for heavy-duty applications in concrete construction.

-

ASTM A193

Bolts made from alloy steel, ideal for high-stress environments.

-

Grade 304 and 316 (Stainless Steel)

For environments requiring high corrosion resistance, such as coastal areas or chemical plants.

-

DIN 933/DIN 931

European standard bolts, commonly used in the construction of buildings, bridges, and other infrastructure projects.

-

A4-70, A4-80 (Stainless Steel)

For marine environments, offering both high strength and resistance to harsh weather conditions.

Our fasteners are produced in accordance with international standards, including ISO and ASTM, ensuring that they meet the specific mechanical and material requirements for your project.

Key Applications of Concrete Bolts

Concrete bolts are critical to various construction applications, providing secure anchoring and fastening in concrete structures. Common uses include:

-

Building Construction

Securing beams, columns, and structural components to concrete foundations and walls.

-

Bridges and Overpasses

Fastening and securing concrete bridge decks, girders, and supports.

-

Industrial Equipment

Anchoring heavy machinery and equipment in industrial and manufacturing settings.

-

Highway and Roadway Construction

Securing traffic barriers, guardrails, and other infrastructure components.

-

Precast Concrete

Attaching elements such as wall panels, beams, and slabs in precast concrete construction.

-

Utility Installations

Fixing utility poles, streetlights, and other infrastructure components to concrete foundations.

-

Marine and Coastal Structures

Securing concrete elements in docks, piers, and seawalls exposed to water and harsh environments.

Each of these applications requires concrete bolts that offer high tensile strength, corrosion resistance, and secure fastening, which is exactly what JM Hardware® provides.

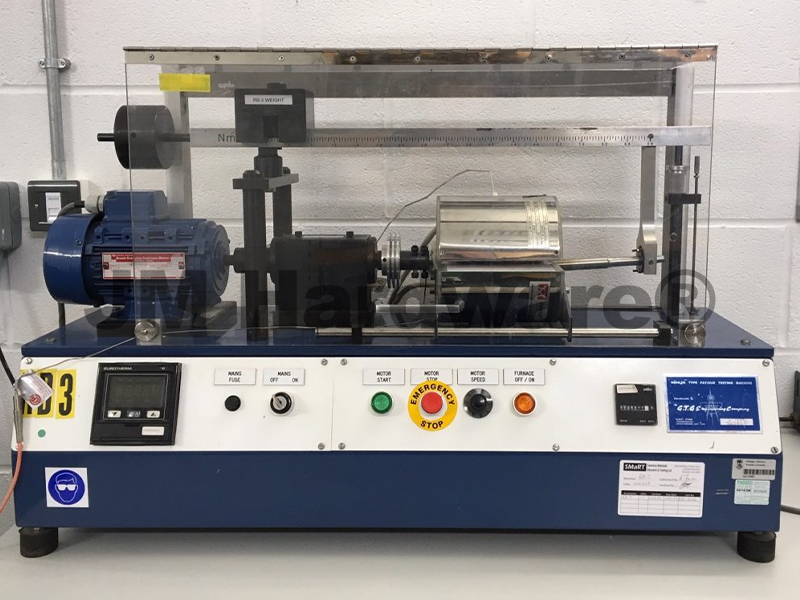

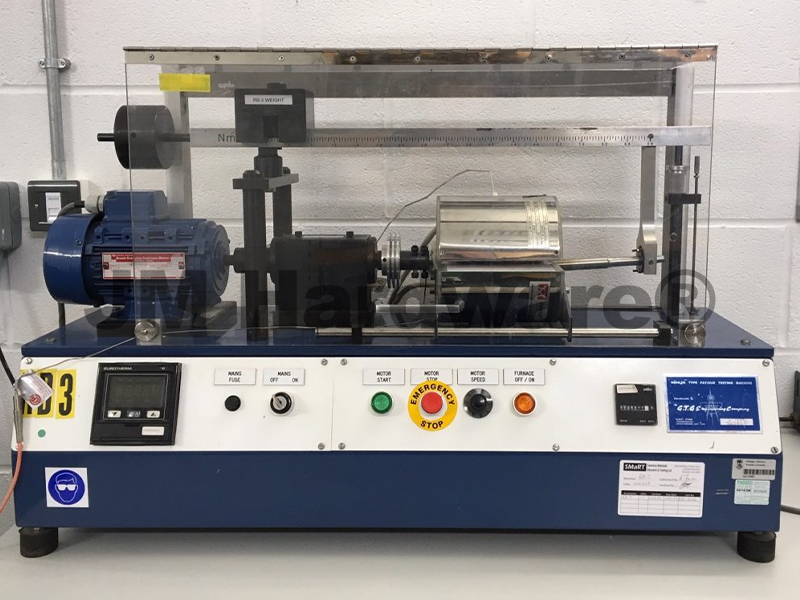

Testing and Quality Assurance

As a trusted Concrete Bolt Manufacturer, JM Hardware® places a strong emphasis on quality control to ensure the performance and safety of our products. Our fasteners undergo a variety of tests, including:

-

Tensile Strength Testing:

Ensures that bolts can withstand high loads without failure.

-

Hardness Testing:

Verifies the bolt material’s hardness to ensure it meets required strength specifications.

-

Corrosion Resistance Testing:

Salt spray tests and other corrosion evaluations ensure our bolts will endure harsh environmental conditions.

-

Dimensional Inspection:

Ensures that bolts meet the precise specifications for thread size, length, and other critical dimensions.

-

Impact Resistance Testing:

Ensures bolts can withstand sudden shocks or impacts, a critical consideration for construction projects in high-traffic areas.

-

Fatigue Testing:

5.Assesses the durability of bolts under repeated load cycles to ensure long-term reliability.

Our commitment to quality ensures that every bolt is manufactured to exceed industry standards, guaranteeing performance and safety in your construction projects.

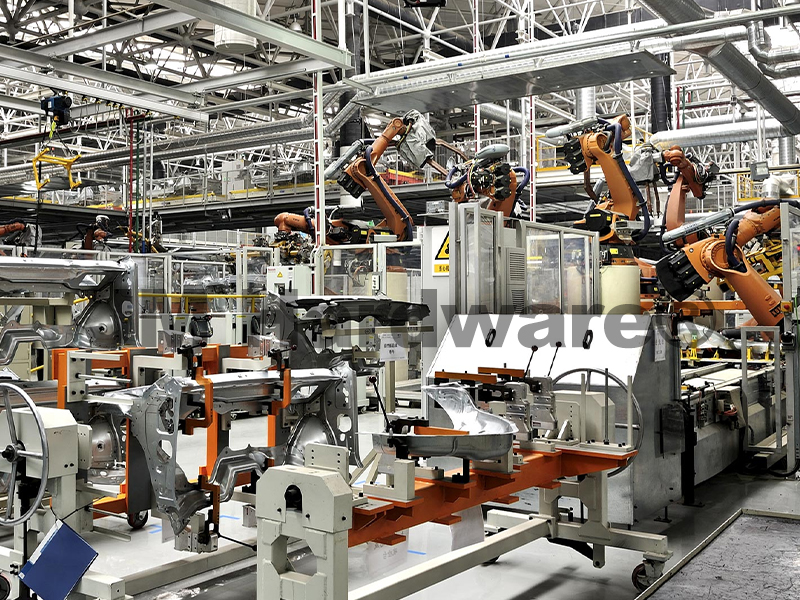

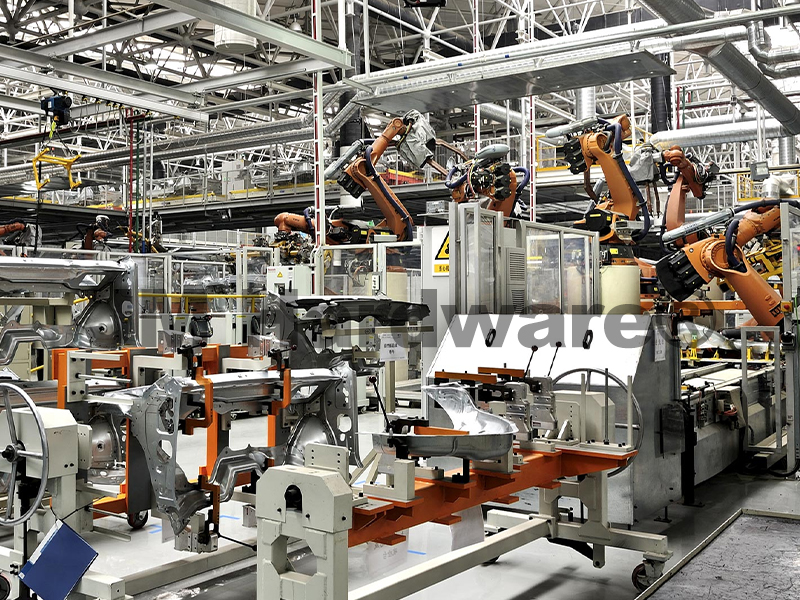

Production Process for Carriage Bolts

Our advanced manufacturing process allows us to deliver bolts that meet the highest standards of quality, precision, and performance:

-

Material Selection:

We choose premium materials based on the specific application and environmental conditions.

-

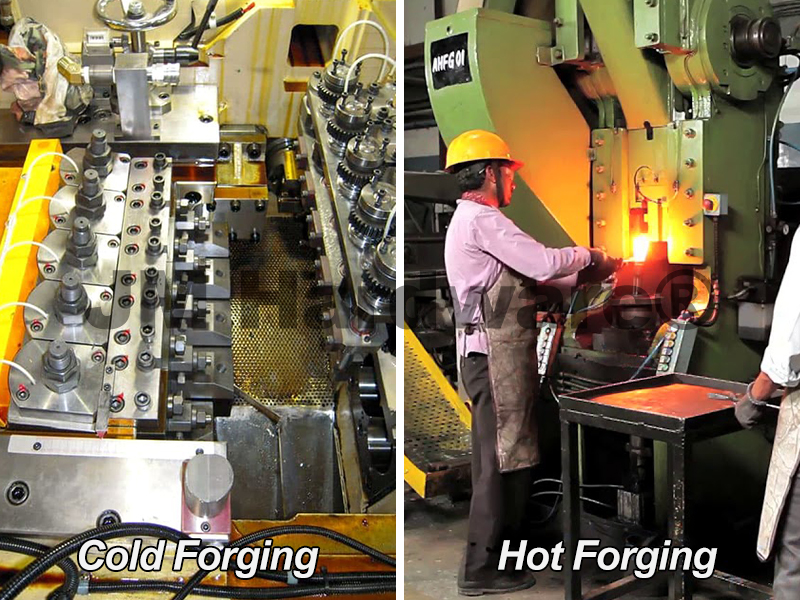

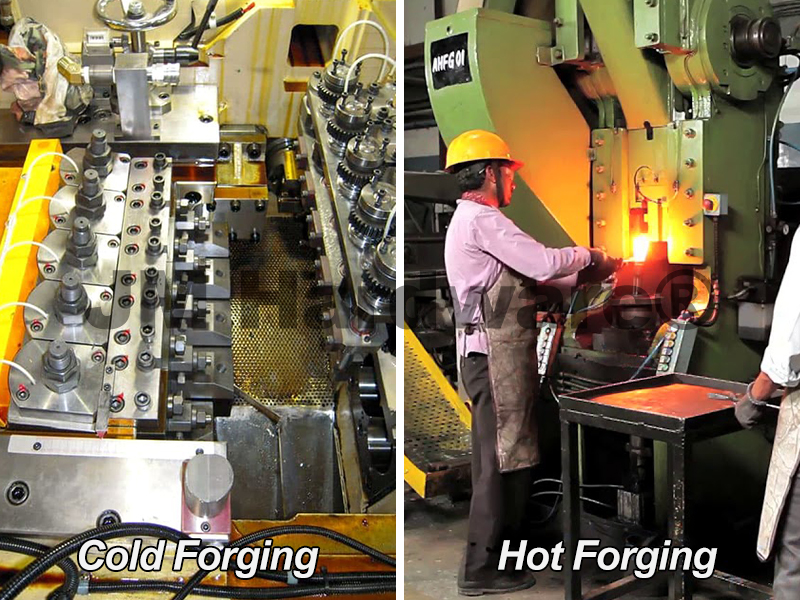

Cold or Hot Forging:

Depending on the application, bolts are either cold forged for general use or hot forged for high-strength requirements.

-

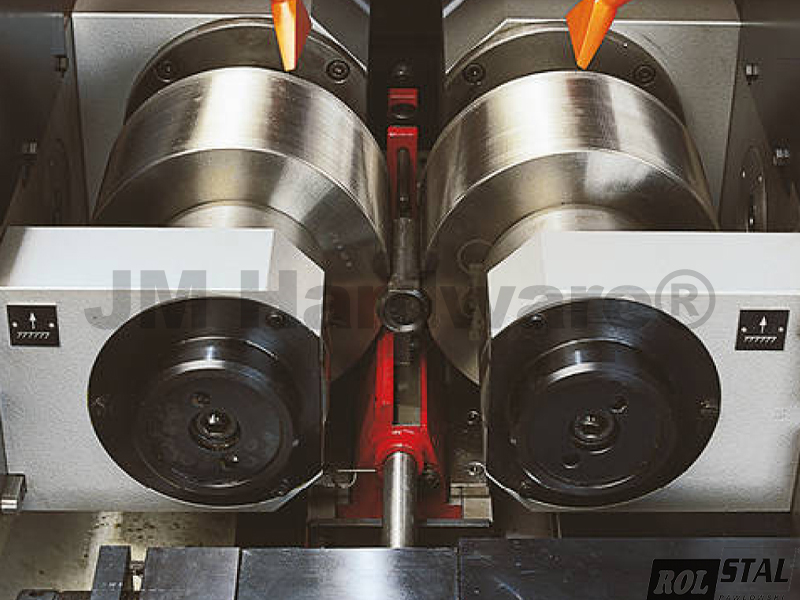

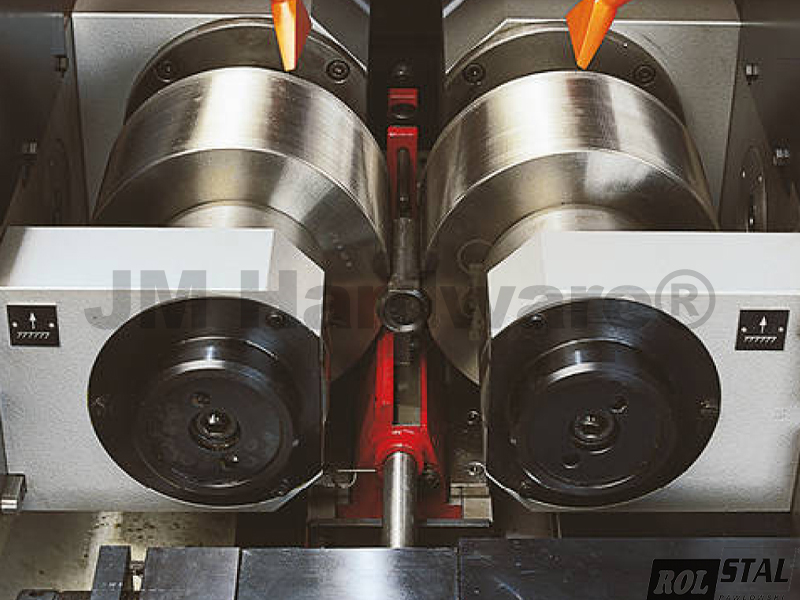

Thread Rolling:

Threads are rolled onto bolts to improve strength and increase durability.

-

Heat Treatment:

Applied to enhance the hardness and strength of the bolts.

-

Surface Coating:

A variety of protective coatings are applied to ensure long-term durability and resistance to environmental factors.

-

Rigorous Quality Control:

All bolts undergo thorough testing and inspections to ensure they meet the highest industry standards.

Why Choose JM Hardware® as Your Concrete bolt Manufacturer?

1.Custom Solutions: We offer tailored fasteners for specific construction needs, ensuring compatibility with your project requirements.

2.Wide Range of Products: From standard to high-strength and corrosion-resistant bolts, we offer an extensive selection of concrete bolts.

3.High-Quality Materials: Our bolts are made from high-quality materials for optimal strength, durability, and corrosion resistance.

4.Global Reach: We provide fasteners to construction projects around the world, ensuring timely delivery and availability.

5.Comprehensive Support: From product selection to post-delivery assistance, we provide end-to-end support for your concrete bolt needs.

6.Competitive Pricing: We offer high-quality bolts at competitive prices to fit your budget while maintaining exceptional performance.

Contact JM Hardware® for Concrete bolt Solutions

Whether you are constructing bridges, securing industrial equipment, or building new infrastructure, JM Hardware® offers high-quality concrete bolts that are perfect for any project. Contact us today to discuss your fastener requirements, request a custom quote, or place an order. Let JM Hardware® be your trusted partner for all concrete bolt solutions!