-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a trusted Allen bolt manufacturer, offering a wide variety of Allen bolts for diverse industrial applications. Known for their durability and precision, Allen bolts (also known as hexagon socket head cap screws) are widely used in industries that demand strong, reliable fastening solutions. From mechanical and automotive applications to structural projects and precision machinery, we manufacture Allen bolts designed to meet the most demanding requirements.

Different Names for Allen Bolts

Allen bolts are commonly referred to by several other names, depending on the region and application. Some of these names include:

-

Hex Socket Cap Screws

-

Hexagon Socket Screws

-

Hex Head Bolts(for square pipes and channels)

-

Hex Socket Head Cap Screws (SHCS)

-

Allen Head Screws(customized to specific dimensions or finishes)

-

Socket Head Cap Screws(customized to specific dimensions or finishes)

These bolts are characterized by their cylindrical heads with a hexagonal recess designed to be driven by an Allen wrench or hex key, offering higher torque transmission and ease of use in tight spaces.

Materials Used in Allen Bolt Manufacturing

As a leading Allen bolt manufacturer, we understand that the material selection is crucial for the performance, strength, and longevity of our products. We offer Allen bolts in a range of materials suitable for different environmental conditions and application requirements:

-

Carbon Steel:

Ideal for general-purpose applications, offering great tensile strength and cost efficiency.

-

Stainless Steel (SS304, SS316):

Offers superior corrosion resistance, making it perfect for outdoor, marine, and chemical applications.

-

Alloy Steel:

High-strength material used in heavy-duty applications, including aerospace, automotive, and machinery.

-

Boron Steel:

Excellent for wear-resistant applications, ideal for parts exposed to friction.

-

Brass:

Non-magnetic and corrosion-resistant, suitable for applications in electrical industries or where conductivity is important.

-

Titanium:

Offers exceptional strength-to-weight ratio, ideal for high-performance industries like aerospace and medical.

-

Aluminum:

Lightweight and corrosion-resistant, commonly used for applications that require a balance between strength and weight.

Surface Treatments for Allen Bolts

We provide a wide range of surface treatments to enhance the performance and durability of our Allen bolts.These treatments are essential for improving corrosion resistance, reducing friction, and enhancing aesthetics:

-

Zinc Plating:

Provides moderate corrosion resistance, commonly used for indoor applications.

-

Hot-Dip Galvanizing:

Offers superior corrosion protection for outdoor applications exposed to harsh weather conditions.

-

Black Oxide:

Adds a sleek black finish and provides minimal corrosion resistance, often used for aesthetic purposes or in low-humidity environments.

-

Teflon Coating:

Non-stick coating that provides resistance to chemicals, reducing wear and tear in industrial applications.

-

Phosphate Coating:

Offers corrosion resistance and lubrication for industrial and automotive applications.

-

Nickel Plating:

Enhances appearance while offering additional corrosion protection, suitable for decorative applications and machinery.

-

Passivation(for stainless steel):

Enhances the natural corrosion resistance of stainless steel, often used for medical and food processing equipment.

Grades of Allen Bolts

As an experienced Allen bolt manufacturer, we provide a range of Allen bolts in various grades to ensure that they meet the specific strength and durability requirements of your projects. Some of the most common grades include:

-

Grade 5:

Commonly used for general-purpose applications, offering moderate tensile strength.

-

Grade 8:

High-strength bolts used for heavy-duty applications, such as machinery, automotive, and structural projects.

-

ASTM A193 Grade B7:

Alloy steel bolts for high-temperature applications, typically used in power plants and chemical processing.

-

ASTM A320 Grade L7:

Low-temperature grade bolts for applications in cold environments, such as cryogenic systems.

-

Grade 12.9:

High-performance bolts with excellent tensile strength, ideal for industrial and automotive applications requiring high strength and reliability.

-

ASTM A307:

Used for general industrial applications, offering moderate strength and a good balance between price and performance.

Standards for Allen Bolts

To ensure our Allen bolts meet the required performance standards, we manufacture them according to internationally recognized standards. These include:

-

ISO 4762:

The international standard for hexagon socket head cap screws, covering dimensions and strength requirements.

-

DIN 912:

The German standard for hex socket screws, used primarily in European markets.

-

ASTM A574:

Defines specifications for alloy steel socket head cap screws for use in high-stress applications.

-

BS 4168:

A British standard for socket head cap screws, ensuring compatibility and safety for engineering projects.

-

JIS B1189:

The Japanese Industrial Standard for socket head cap screws, commonly used in the Asia-Pacific region.

-

EN ISO 4762:

European standard for socket head screws, ensuring they meet the requirements for strength and quality.

These standards ensure that our Allen bolts conform to global specifications for safety, durability, and performance.

Applications of Allen Bolts

Allen bolts are used in a wide variety of industries due to their strength, precision, and ease of installation. Common applications include:

-

Automotive Industry:

For securing components in engines, suspension systems, and bodywork.

-

Aerospace:

Used in high-strength applications requiring precise fastening and corrosion resistance.

-

Construction:

Securely fastening structural components like steel beams, brackets, and frames.

-

Heavy Machinery:

Used in equipment like bulldozers, cranes, and excavators, where high load-bearing capacity is crucial.

-

Electronics:

Precision fastening for electronic equipment and enclosures, particularly in the telecom sector.

-

Furniture:

Securing components in assembled furniture and fittings.

-

Marine Industry:

For securing components that are exposed to saltwater and other harsh environmental factors.

-

Industrial Equipment:

Used in various machines and devices where secure, vibration-resistant fastening is required.

Quality Assurance and Testing

As an experienced Allen bolt manufacturer, we take quality seriously. We subject each bolt to rigorous testing to ensure they meet the required specifications. Some of our key testing methods include:

-

Tensile Strength Testing:

To verify that bolts can withstand the expected loads without failure.

-

Hardness Testing:

To confirm the material's hardness and ensure proper strength and durability.

-

Corrosion Resistance Testing:

Including salt spray tests to ensure durability in harsh environments.

-

Dimensional Inspection:

To ensure precise fit and thread quality for compatibility with other components.

-

Vibration and Impact Testing:

To ensure that fasteners remain secure under high-vibration conditions.

Production Process of Allen Bolts

Our Allen bolts are manufactured using state-of-the-art technology and the highest quality materials. The process includes:

-

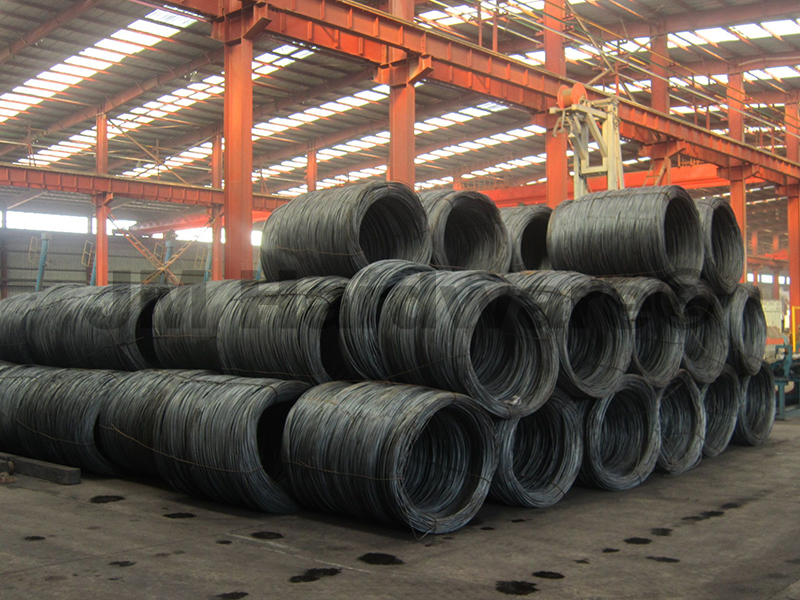

Material Selection:

We start with premium raw materials to ensure the strength and longevity of each bolt.

-

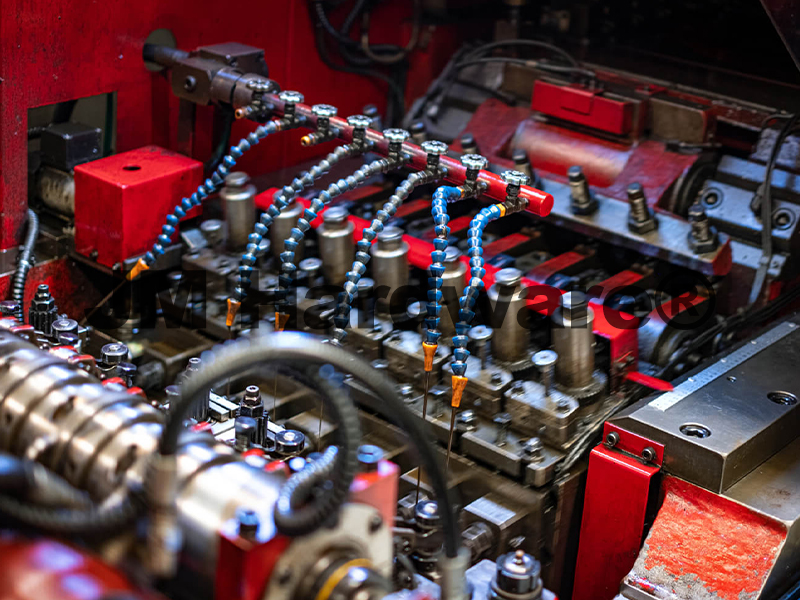

Forging and Shaping:

The bolts are forged or cold-formed to achieve the desired dimensions and thread profiles.

-

Thread Rolling:

Precision thread rolling enhances the strength and durability of the bolts, improving their resistance to wear and tear.

-

Heat Treatment:

Bolts are heat-treated to enhance their strength, hardness, and corrosion resistance.

-

Surface Finishing:

Depending on the application, bolts may undergo surface treatments such as galvanizing, anodizing, or plating.

-

Final Inspection:

Each bolt undergoes a thorough inspection to ensure it meets dimensional, material, and quality specifications before being shipped.

Why Choose JM Hardware® as Your Allen Bolt Manufacturer?

1.Wide Product Range: We offer a broad selection of Allen boltsin various materials, grades, and finishes to meet your specific project needs.

2.Customization: Custom sizes, materials, and coatings available for specialized applications.

3.High-Quality Materials: Our bolts are made from high-strength materials that ensure long-term performance.

4.Global Shipping: We ensure timely and reliable delivery to projects worldwide.

5.Expertise: Decades of experience as a trusted Allen bolt manufacturerin various industries.

6.Competitive Pricing: We provide top-quality fasteners at competitive prices without compromising on performance.

Contact JM Hardware® for Allen Bolt Solutions

Looking for high-quality Allen bolts for your next project? JM Hardware® is here to provide durable, reliable, and high-performance fasteners. Contact us today for a custom quote or to discuss your specific requirements. Let us be your trusted partner for all your Allen bolt needs!