-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we take pride in being a leading carriage bolt manufacturer, specializing in the production of high-quality carriage bolts that offer exceptional strength, durability, and versatility. Our carriage bolts are designed for a variety of applications, from construction and woodworking to automotive and heavy-duty equipment. With extensive experience and a commitment to delivering the highest standards of quality, we provide fasteners that meet the most demanding needs of industries worldwide.

Different Names for Carriage Bolts

Carriage bolts are known by various names across different regions and applications, including:

-

Coach Bolts:

Commonly used in some areas for construction and woodworking.

-

Round Head Bolts:

Describing the shape of the bolt head.

-

Square Neck Bolts:(for square pipes and channels)

Due to their square neck that prevents rotation when installed.

-

Tamper-Proof Bolts:

Often used in outdoor installations where tampering is a concern.

-

Slotted Head Bolts: (customized to specific dimensions or finishes)

Referring to the slotted head design of the carriage bolt.

Carriage bolts feature a smooth, rounded head with a square neck that locks into place during installation, preventing rotation and ensuring a secure, stable connection.

Materials Used in Carriage Bolt Manufacturing

As a trusted carriage bolt manufacturer, we offer carriage bolts in various materials that ensure optimal performance, strength, and corrosion resistance for different applications:

-

Carbon Steel:

Ideal for general-purpose applications where high strength and affordability are essential.

-

Stainless Steel (SS304, SS316):

Perfect for outdoor and corrosive environments, offering excellent corrosion resistance.

-

Alloy Steel:

Used for high-strength applications where added durability is needed.

-

Hot-Dip Galvanized Steel:

Offers superior corrosion resistance, particularly for outdoor or marine applications.

-

Brass:

Offers good corrosion resistance and aesthetic appeal for decorative uses, including furniture and cabinetry.

-

Aluminum:

Lightweight and corrosion-resistant, and ideal for applications where weight is a concern.

-

Boron Steel:

Known for its enhanced wear resistance, often used in automotive or heavy machinery applications.

We also offer custom material options depending on your project’s specific requirements, ensuring our bolts meet your performance standards.

Surface Finishes for Carriage Bolts

The performance and longevity of carriage bolts can be significantly enhanced through various surface treatments. Our range of surface finishes includes:

-

Zinc Plating:

Offers a moderate level of protection against rust and corrosion, typically used in indoor or low-humidity environments.

-

Hot-Dip Galvanizing:

Provides long-lasting corrosion protection, ideal for outdoor use in harsh weather conditions.

-

Black Oxide Coating:

Aesthetic black finish that provides a degree of rust resistance, suitable for decorative applications.

-

Epoxy Coating:

Provides a protective layer that is resistant to chemicals, corrosion, and abrasions, ideal for industrial settings.

-

Dacromet Coating:

A superior corrosion-resistant coating ideal for heavy-duty, high-stress applications in outdoor environments.

-

Powder Coating:

Delivers excellent durability and a smooth, attractive finish for various outdoor and industrial applications.

-

Passivation(for stainless steel):

Applied to stainless steel carriage bolts to increase resistance to rust and corrosion.

These coatings not only enhance the bolt’s aesthetic appeal but also significantly improve their performance in various environmental conditions.

Grades of Carriage Bolts

As a leading bolt manufacturer, we provide bolts with internal threads in various grades, depending on their strength and application requirements. Common grades include:

-

Grade 4.8, 8.8, 10.9, and 12.9 (Carbon Steel)

Standard strength bolts for general-purpose use.

-

Grade A193 B7(Alloy Steel)

Alloy steel bolts designed for use in high-pressure, high-temperature environments.

-

ASTM A325

Structural-grade carriage bolts for heavy-duty construction applications.

-

Grade 5

Medium-strength bolts, commonly used in automotive and industrial applications.

-

Grade 8 (Alloy Steel)

High-strength bolts suitable for high-tensile applications.

-

A4-70, A4-80 (Stainless Steel) (Stainless Steel)

Stainless steel carriage bolts for applications requiring superior corrosion resistance.

Each grade is engineered to meet specific mechanical properties, ensuring that our carriage bolts perform reliably in a range of industries.

Standards for Carriage Bolts

To ensure the highest quality, we manufacture carriage bolts that adhere to a variety of international standards:

-

ISO 9001:

Quality management system ensuring product consistency and reliability.

-

DIN(Deutsches Institut für Normung):

European standards for carriage bolt dimensions, threads, and material properties.

-

ASTM (American Society for Testing and Materials):

Standards for mechanical properties and performance specifications.

-

SAE J429:

Industry standard for bolts used in automotive and mechanical applications.

-

BS (British Standards):

Ensures the bolts meet stringent mechanical and dimensional tolerances in the UK.

-

JIS (Japanese Industrial Standards):

Specifications for bolt design, dimensions, and performance in industrial applications.

These standards guarantee that our carriage bolts are manufactured with precision and are suitable for various critical applications.

Applications of Carriage Bolts

Carriage bolts are widely used in a variety of applications that require secure, stable fastening with minimal maintenance. Common applications include:

-

Automotive Industry:

Used to assemble car frames, bumpers, and structural components that require high-strength connections.

-

Furniture Assembly:

Often used in assembling wooden furniture, where a strong, secure connection is needed.

-

Construction:

Securing timber and steel components in building frameworks and substructures.

-

Electrical Enclosures:

Securing electrical components and cabinets in telecom and utility systems.

-

Bridge Construction:

Essential for connecting bridge components, including beams, decking, and supports.

-

Woodworking:

Common in timber framing and connecting wooden beams and posts.

-

Heavy Machinery:

Used to fasten heavy machinery components and assemblies that require resistance to vibration and high loads.

-

Railroads:

Used for securing components in railroad track systems and related infrastructure.

Our carriage bolts offer the strength and reliability needed for both structural and decorative applications, providing versatile solutions across industries.

Quality Assurance and Testing

At JM Hardware®, quality is at the core of everything we do. We follow stringent quality control processes to ensure that each carriage bolt meets the highest standards:

-

Tensile Strength Testing:

Verifies the bolt’s ability to withstand the required loads without failure.

-

Hardness Testing:

Ensures that the material meets the required hardness specifications for durability.

-

Corrosion Resistance Testing:

Confirms the performance of coatings in harsh environments.

-

Dimensional Inspection:

Ensures the bolt meets the precise measurements and thread specifications for a perfect fit.

-

Impact Testing:

Verifies that the bolt can withstand high-stress impacts without breaking or failing.

-

Fatigue Testing:

Assesses the bolt’s ability to endure repeated load cycles without degradation.

Production Process for Carriage Bolts

We employ advanced manufacturing techniques to produce carriage bolts with consistent quality and high precision. Our production process includes:

-

Material Selection:

We use high-quality raw materials sourced from trusted suppliers, ensuring that every bolt meets the required specifications.

-

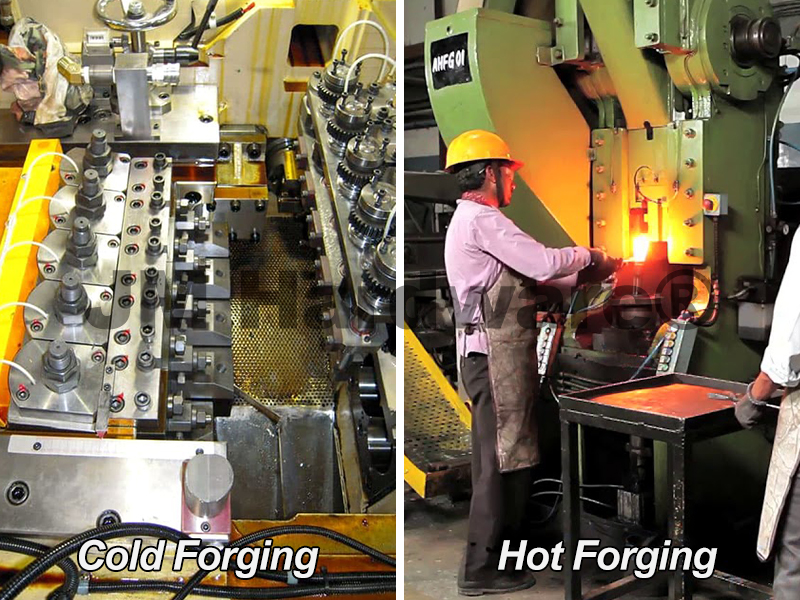

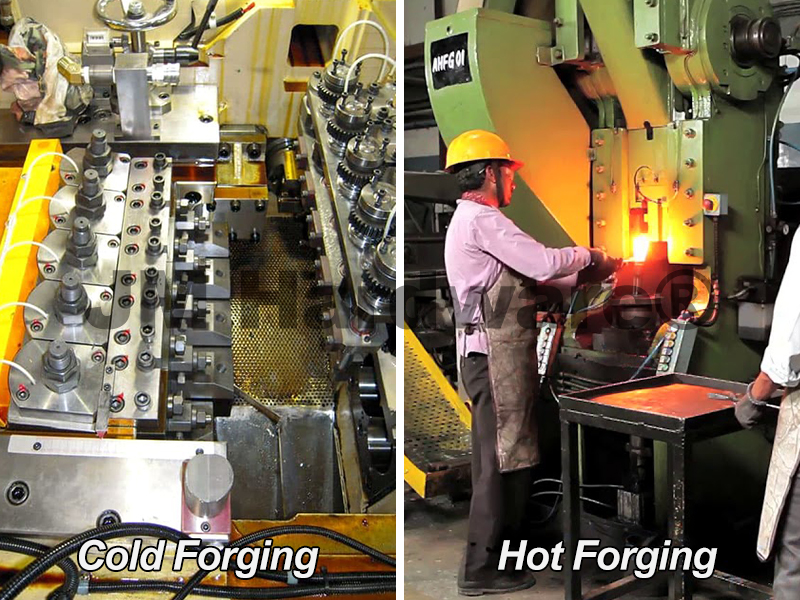

Forging:

The bolts are forged using precise machinery, creating a solid, uniform structure that meets strength and durability standards.

-

Thread Rolling:

Threads are rolled onto the bolts for increased strength and to avoid material loss, ensuring a tight, durable fit.

-

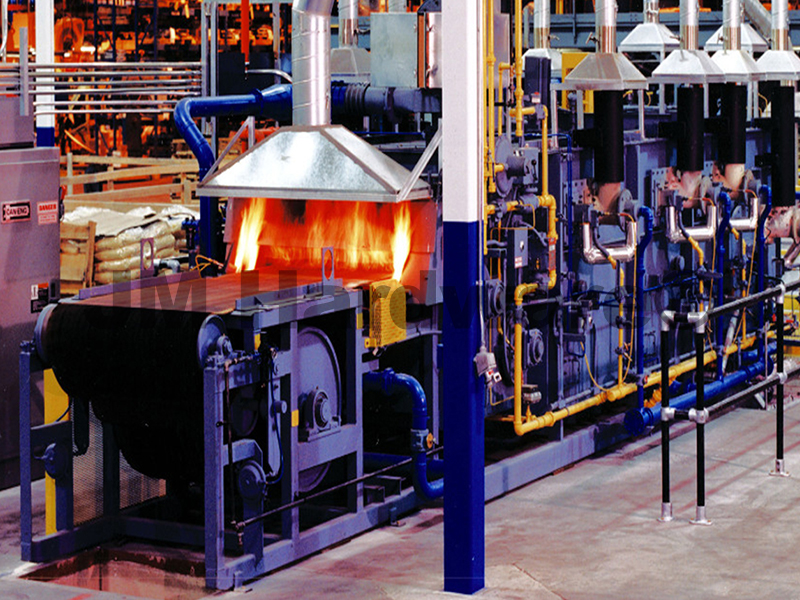

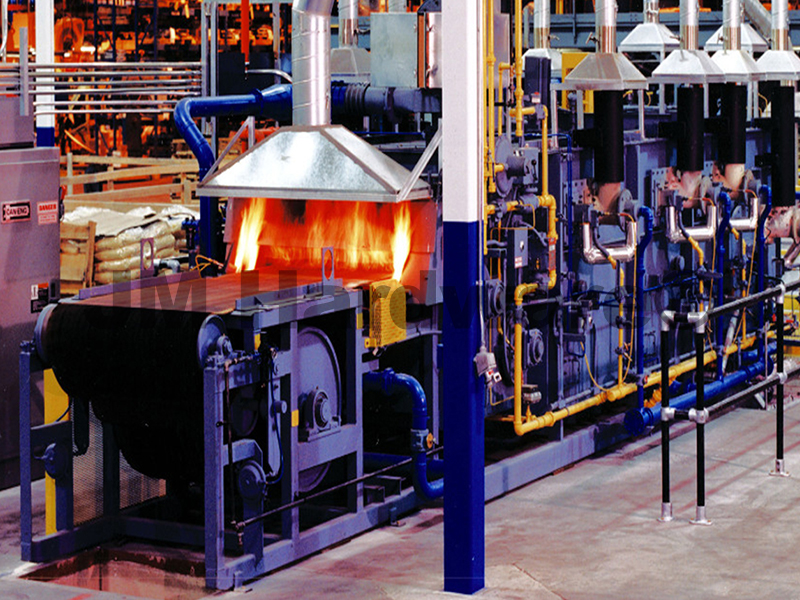

Heat Treatment:

Bolts undergo heat treatment to enhance their mechanical properties, such as hardness and strength.

-

Coating and Finishing:

Surface treatments like galvanizing, plating, or powder coating are applied to improve corrosion resistance and extend the lifespan of the bolts.

-

Final Inspection:

Every carriage bolt undergoes rigorous quality checks to ensure it meets the specified dimensions, material properties, and finish.

Why Choose JM Hardware® as Your Carriage Bolt Manufacturer?

1.Extensive Product Range: We offer a wide selection of carriage bolts, from standard designs to custom solutions.

2.High-Quality Materials: We use premium-grade materials to ensure strength, durability, and long-lasting performance.

3.Customization: Tailored solutions for unique specifications, including custom sizes, threads, and finishes.

4.Reliable Delivery: We ensure timely delivery of all orders, whether you require small or large quantities.

5.Competitive Pricing: We offer high-quality carriage bolts at affordable prices, making us a cost-effective choice for your fastener needs.

6.Proven Expertise: With years of experience in the fastener manufacturing industry, we are a trusted partner for construction, automotive, and industrial projects.

Contact JM Hardware® for Carriage bolt Solutions

Whether you are working on construction, automotive, or industrial projects, JM Hardware® has the right carriage bolts for your application. Contact us today to discuss your needs or request a custom quote. We are your trusted bolt manufacturer, providing high-quality fasteners for a variety of industries!