-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a trusted Tension Control Structural Bolt Manufacturer offering premium fastening solutions for construction, infrastructure, and industrial applications. Tension control (TC) bolts are designed for high-strength structural connections, providing exceptional durability, reliability, and ease of installation. As an experienced manufacturer, we pride ourselves on delivering high-quality TC bolts that meet the rigorous demands of global industries. Whether for bridges, skyscrapers, or power plants, JM Hardware® ensures precision-engineered bolts that guarantee performance under the toughest conditions.

What Are Tension Control Structural Bolts?

Tension control bolts, also known as TC bolts or torque-controlled bolts, are a specialized type of structural fastener used in heavy-duty applications. These bolts feature a unique design with a splined end that shears off when the correct tension is achieved during installation. This ensures uniformity, reduces installation errors, and provides visual confirmation of proper tightening. TC bolts are widely used in projects requiring structural integrity and reliability.

Key Features of Tension Control Bolts

-

Precision Tensioning:

Ensures consistent bolt tension, reducing the risk of over- or under-tightening.

-

Ease of Installation:

No torque wrench is required; installation uses a shear wrench for fast and efficient tightening.

-

High Strength:

Designed for structural applications requiring superior load-bearing capacity.

-

Visual Confirmation:

The splined end shears off when proper tension is reached, ensuring every bolt is correctly installed.

-

Corrosion Resistance:

Available in various materials and finishes to withstand harsh environmental conditions.

Materials for Tension Control Structural Bolts

As a professional Tension Control Structural Bolt Manufacturer, we provide bolts in a variety of high-performance materials to meet the unique requirements of your projects:

-

Carbon Steel:

Offers excellent strength and durability for standard construction projects.

-

Stainless Steel (SS304, SS316):

Provides superior corrosion resistance, making it suitable for marine, chemical, and outdoor environments.

-

Alloy Steel:

Ideal for high-strength applications, such as heavy machinery and infrastructure.

-

Weathering Steel (Corten Steel):

Designed for outdoor use, forming a protective rust layer to resist corrosion in bridges and towers.

-

High-Strength Low-Alloy (HSLA) Steel:

Combines strength with excellent weldability, commonly used in large-scale structures.

Surface Treatments for Tension Control Bolts

We offer a variety of surface treatments to enhance the performance, durability, and appearance of TC bolts:

-

Zinc Plating:

Offers a cost-effective solution for moderate corrosion resistance in standard environments.

-

Hot-Dip Galvanizing:

Provides long-lasting protection against rust, ideal for outdoor and marine environments.

-

Teflon Coating:

Excellent resistance to chemicals and friction, suitable for industrial environments.

-

Black Oxide Coating:

Adds a sleek finish with basic corrosion protection, often used for aesthetic purposes.

-

Epoxy Coating:

Delivers advanced corrosion and wear resistance for extreme environments.

-

Phosphate Coating:

Reduces friction and improves corrosion resistance for threaded components.

Applications of Tension Control Structural Bolts

Tension control bolts are essential for various industries and applications where structural integrity is critical:

-

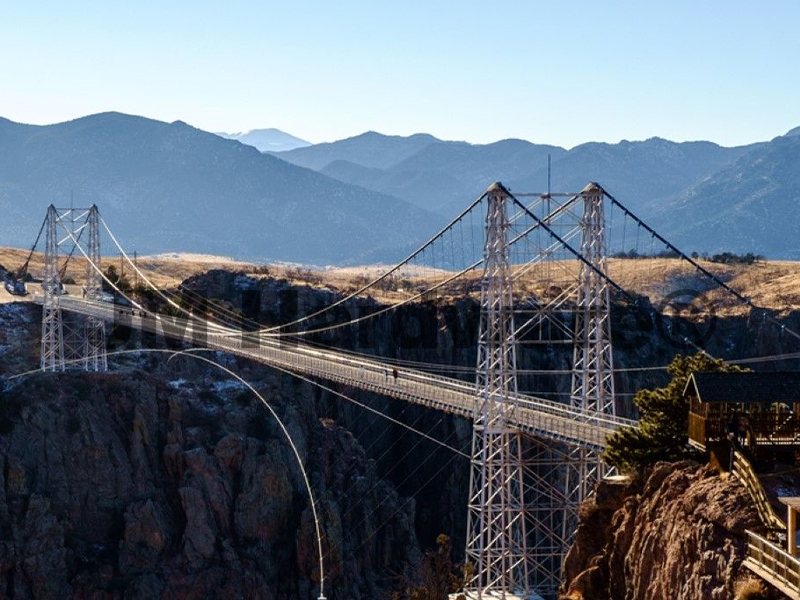

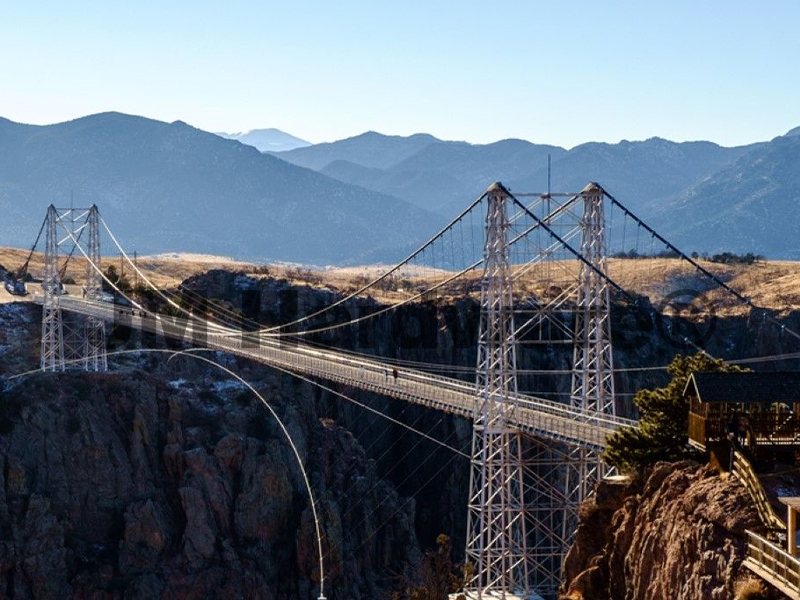

Bridges

Used in the assembly of girders, trusses, and suspension systems to ensure long-term stability.

-

High-Rise Buildings

Fasten structural steel frameworks in skyscrapers and large commercial buildings.

-

Wind Turbines

Fasten tower sections, ensuring durability and reliability under constant wind loads.

-

Railway Infrastructure

Connect structural components of rail bridges and stations.

-

Stadiums and Arenas

Provide structural support for large-scale sports facilities.

-

Cranes and Heavy Equipment

Fasten components in industrial machinery and lifting systems.

-

Oil & Gas Platforms

Secure structural steel in offshore and onshore rigs under harsh environmental conditions.

-

Power Plants

Secure structural components in energy facilities, including nuclear, coal, and hydroelectric plants.

Grades of Tension Control Structural Bolts

Our TC bolts are available in a range of grades to suit different structural and industrial applications:

-

DIN 6914

Widely used in steel construction, offering exceptional strength and reliability.

-

ASTM A325

High-strength bolts for structural steel connections, commonly used in construction and bridges.

-

ISO 898-1 Grade 10.9

Suitable for high-stress applications in industrial and infrastructure projects.

-

ASTM A490

Higher-strength bolts for critical connections requiring extreme load-bearing capabilities.

-

EN 14399-4

European standards for structural bolts with enhanced pre-load properties.

Testing and Quality Assurance

As a leading Tension Control Structural Bolt Manufacturer, we ensure that every product meets the highest quality standards. Our rigorous testing methods include:

-

Tensile Strength Testing:

Verifies the bolt’s ability to withstand applied forces without failure.

-

Corrosion Resistance Testing:

Ensures the fasteners perform reliably in harsh environments.

-

Shear Testing:

Confirms the integrity of the splined end and its ability to shear off at the correct tension.

-

Dimensional Inspection:

Ensures precise thread dimensions and bolt lengths for seamless installation.

-

Vibration Testing:

Ensures that the bolt maintains its integrity under continuous vibration.

-

Hardness Testing:

Ensures the material meets the required hardness levels for durability.

Production Process for Tension Control Bolts

Our advanced manufacturing processes ensure precision and reliability in every TC bolt we produce:

-

Material Selection:

We use premium raw materials to meet strength and durability requirements.

-

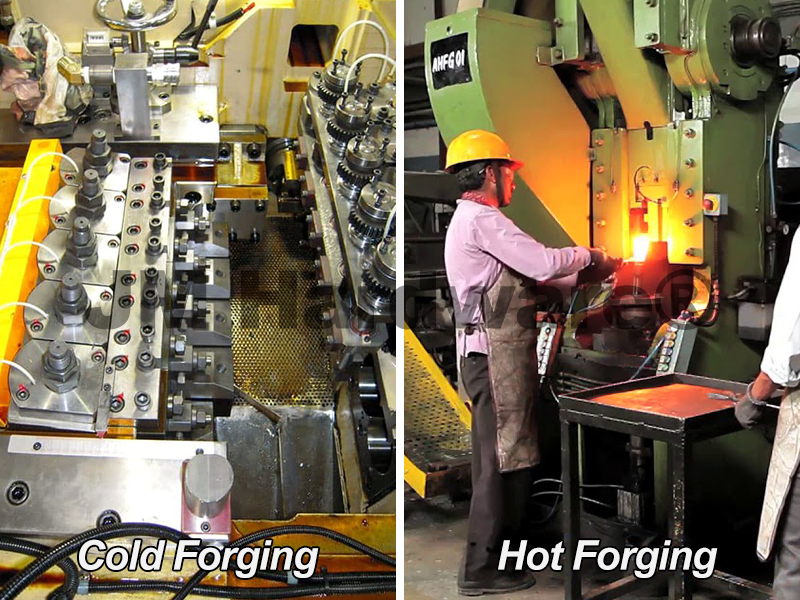

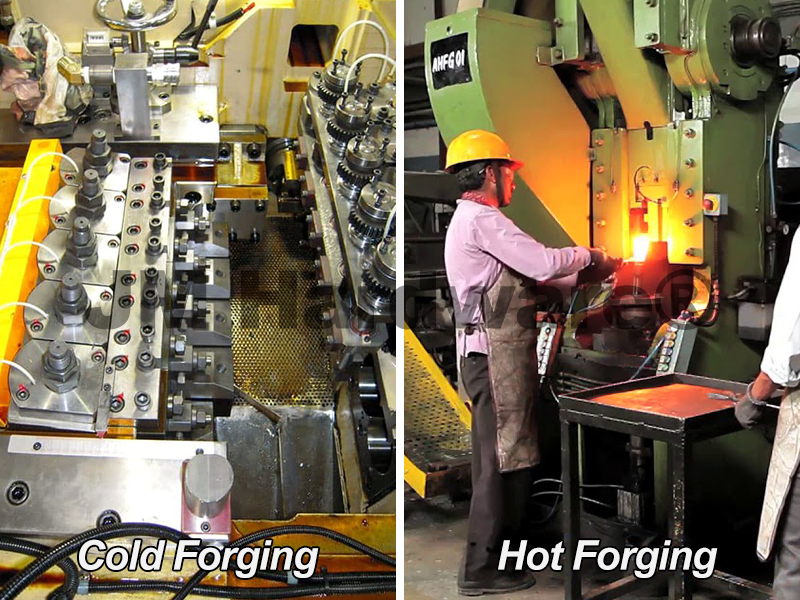

Cold or Hot Forging

Bolts are forged to ensure uniformity and strength.

-

Thread Rolling:

Threads are rolled, not cut, to enhance strength and durability.

-

Heat Treatment:

Bolts are heat-treated to achieve the desired mechanical properties.

-

Surface Coating:

Coatings and finishes are applied to enhance corrosion resistance and overall performance.

-

Quality Control:

Each bolt is inspected and tested to ensure compliance with customer specifications and industry standards.

Why Choose JM Hardware® as Your Tension Control Structural Bolt Manufacturer?

1.Extensive Product Range: From ASTM A325 to custom grades, we provide bolts for all structural applications.

2.Custom Solutions: Tailored designs, sizes, and finishes to meet your unique project requirements.

3.Global Expertise: Proven track record in delivering high-quality bolts to international markets.

4.Durable and Reliable: Designed to withstand extreme loads, harsh environments, and long-term use.

5.Advanced Manufacturing: State-of-the-art facilities ensure precision and efficiency in every product.

6.Competitive Pricing: High-quality products at affordable prices for large-scale and specialty projects.

7.Fast Delivery: Efficient logistics and inventory management ensure on-time delivery worldwide.

Contact JM Hardware® for Your Tension Control Bolt Needs

As a trusted Tension Control Structural Bolt Manufacturer, we are committed to delivering the highest quality fasteners for your projects. Contact us today to discuss your requirements, request a custom solution, or receive a competitive quote. Let JM Hardware® be your reliable partner for premium structural bolts that ensure the success of your projects!