-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing Foundation anchor bolts tailored to meet the demanding requirements of various industries, including construction, infrastructure, power plants, and oil & gas projects. As a leading Foundation anchor bolt manufacturer, we provide reliable, high-quality, and customizable solutions that ensure the structural integrity of your projects. Our advanced manufacturing capabilities and strict quality control processes make us the ideal partner for your anchor bolt needs.

What Are Foundation Anchor Bolts?

Headed anchor bolts are essential fasteners used to secure structural and non-structural elements to concrete. They feature a forged or welded head at one end, ensuring superior grip and load transfer within the concrete structure. Commonly used in foundations, bridges, power plants, and other critical applications, Foundation anchor bolts are renowned for their durability and performance in high-load scenarios.

Different Names for Foundation Anchor Bolts

Foundation anchor bolts are known by several names across industries, highlighting their versatility and application:

-

Headed Bolts

-

Anchor Stud Bolts

-

Concrete Foundation Bolts

-

Embedded Anchor Bolts

-

Heavy-Duty Foundation Bolts

-

Steel Anchor Bolts with Heads

These fasteners come in various types and designs to meet diverse project requirements.

Types of Foundation Anchor Bolts We Manufacture

As a specialized foundation anchor bolt manufacturer, we produce a wide range of bolt types to meet industry needs:

-

Hex Head Anchor Bolts:

Designed for superior gripping and fastening strength.

-

Square Head Anchor Bolts:

Commonly used for heavy-duty industrial applications.

-

Square bend J bolt:

Square bend J bolt:Suitable for structural foundations requiring smooth finishes.

-

Foundation anchor bolts with sleeves:

Ideal for embedded concrete applications and pre-engineered structures.

-

F-Head Anchor Bolts:

Custom-designed for specific load and concrete requirements.

-

Heavy Hex Anchor Bolts:

Engineered for high-tensile strength applications.

Materials Used for Foundation Anchor Bolts

Foundation anchor bolts must endure significant loads, environmental factors, and prolonged use. At JM Hardware®, we manufacture bolts in a variety of materials to suit different applications:

-

Carbon Steel:

Widely used for general construction, offering excellent tensile strength and cost-effectiveness.

-

Stainless Steel (SS304, SS316):

Provides superior corrosion resistance, making it ideal for marine, chemical, and outdoor applications.

-

Alloy Steel:

Perfect for high-load scenarios due to its exceptional strength and durability.

-

High-Strength Steel (ASTM A193 Grade B7):

Engineered for extreme conditions, such as oil & gas applications.

-

Galvanized Steel:

Hot-dip galvanized bolts offer long-lasting protection against corrosion.

-

Duplex Stainless Steel:

Combines strength and corrosion resistance, suitable for harsh industrial environments.

-

Special Alloys:

For specific industry needs, including Hastelloy, Inconel, and Monel.

Surface Finishes for Enhanced Durability

Our anchor bolts are available in a variety of finishes to ensure durability, corrosion resistance, and adaptability to challenging environments:

-

Zinc Plating:

Cost-effective rust protection for indoor or low-exposure environments.

-

Hot-Dip Galvanizing:

Provides exceptional corrosion resistance, especially for outdoor and marine projects.

-

Teflon Coating:

Chemical-resistant and ideal for industrial environments.

-

Epoxy Coating:

Excellent protection against moisture, chemicals, and harsh weather.

-

Black Oxide Coating:

Enhances aesthetics and provides moderate corrosion protection.

-

Phosphate Coating:

Reduces friction during installation and offers basic corrosion resistance.

Applications of Foundation Anchor Bolts

Foundation anchor bolts play a critical role in securing structural components and foundations. They are widely used in:

-

Highway and Transportation Infrastructure

Supporting signposts, guardrails, and light poles.

-

Bridges and Overpasses

Connecting structural elements in high-stress, load-bearing environments.

-

Building Foundations

Securely fastening steel columns and beams to concrete bases.

-

Power Plants

Providing support for heavy machinery and equipment.

-

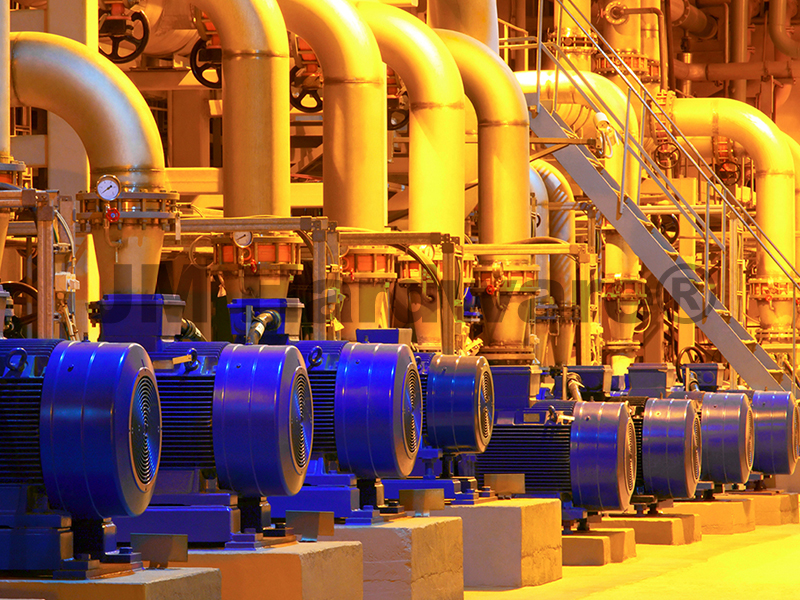

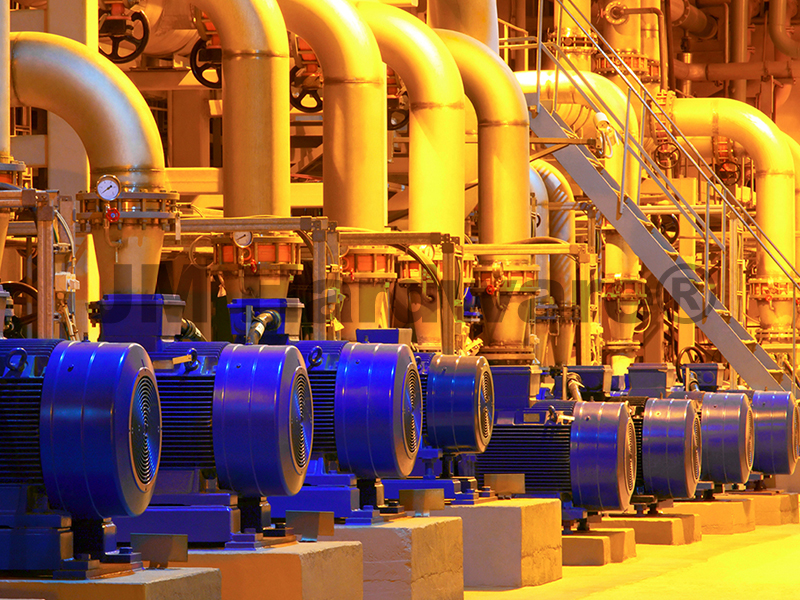

Oil & Gas Industry

Securing pipelines, storage tanks, and offshore platforms.

-

Industrial Equipment

Fastening machinery to concrete foundations for stability.

-

Renewable Energy Projects

Anchoring wind turbines, solar panel arrays, and hydroelectric systems.

Standards and Grades for Foundation Anchor Bolts

As a trusted foundation anchor bolt manufacturer, we ensure our products meet international standards and grades to guarantee their performance and reliability:

-

ISO 898

International standards for strength and mechanical properties.

-

DIN 529

European standard for anchor bolts.

-

ASTM A325 & A490

High-strength structural bolts for demanding applications.

-

ASTM A307

Carbon steel bolts for general-purpose construction.

-

ASTM A193 Grade B7 & B16

For high-pressure and high-temperature environments..

-

ASTM F1554

Specifically designed for anchor bolts in structural applications, available in Grades 36, 55, and 105.

Quality Assurance and Testing

At JM Hardware®, we maintain the highest quality standards to ensure our headed anchor bolts deliver superior performance. Our quality control process includes:

-

Tensile Testing:

Ensures bolts can handle high loads and stress.

-

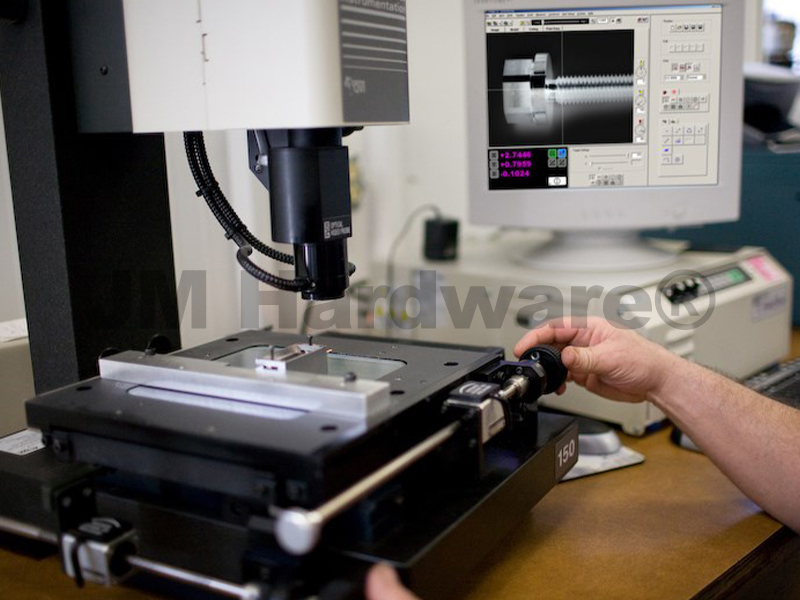

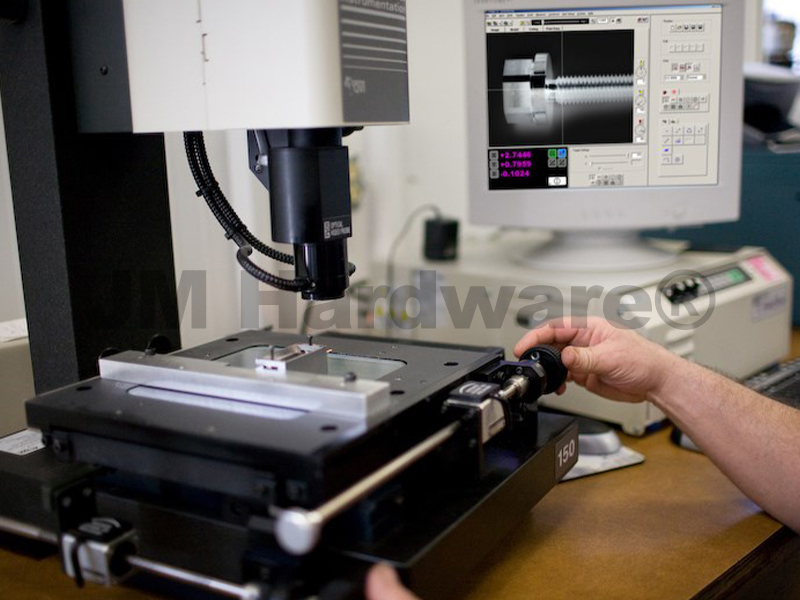

Non-Destructive Testing (NDT)

Identifies internal flaws or defects without damaging the product.

-

Corrosion Resistance Testing:

Simulates harsh environments to assess durability.

-

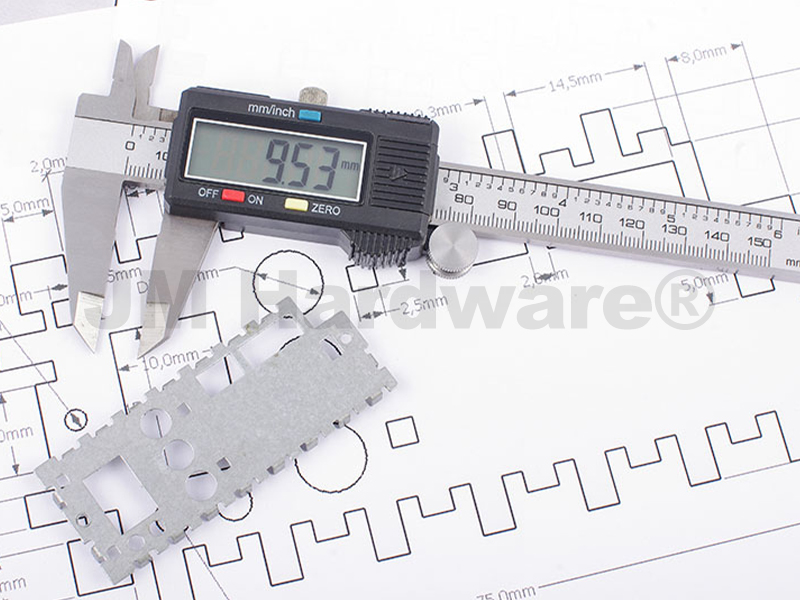

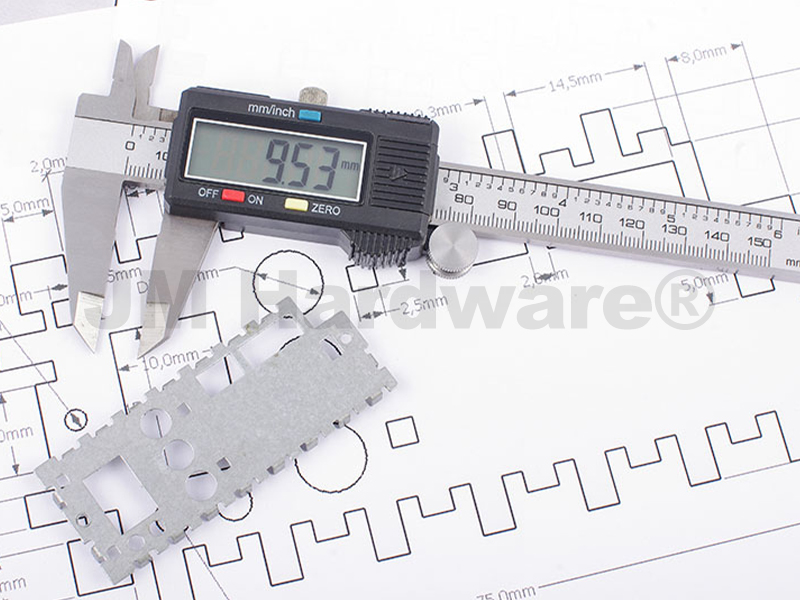

Dimensional Accuracy Testing:

Ensures precise measurements for seamless installation.

-

Impact Resistance Testing:

Evaluates bolt performance under dynamic loads or impacts.

-

Hardness Testing:

Verifies the material’s ability to resist deformation under stress.

Manufacturing Process for Foundation Anchor Bolts

As a leading foundation anchor bolt manufacturer, we utilize advanced production processes to deliver consistent, high-quality products:

-

Raw Material Selection:

Premium materials are sourced to meet strength and corrosion resistance requirements.

-

Forging:

The bolt heads are forged to ensure uniformity and structural integrity.

-

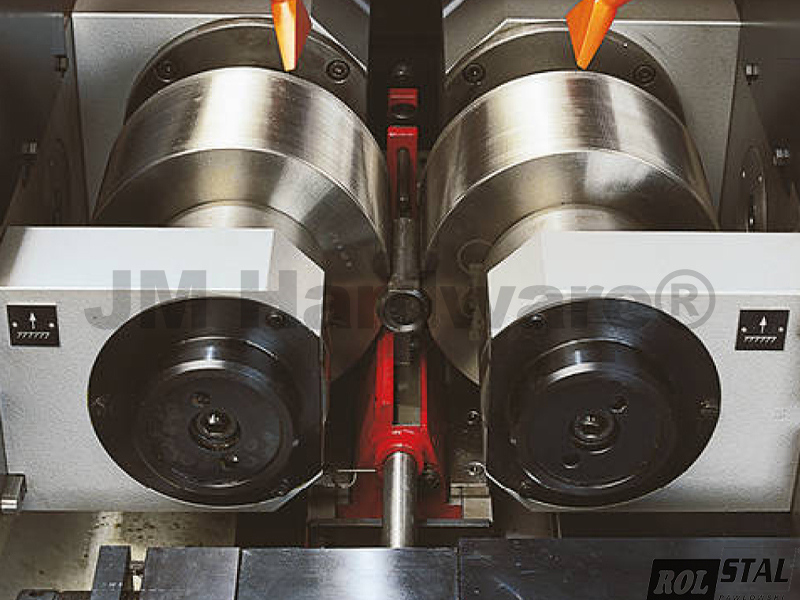

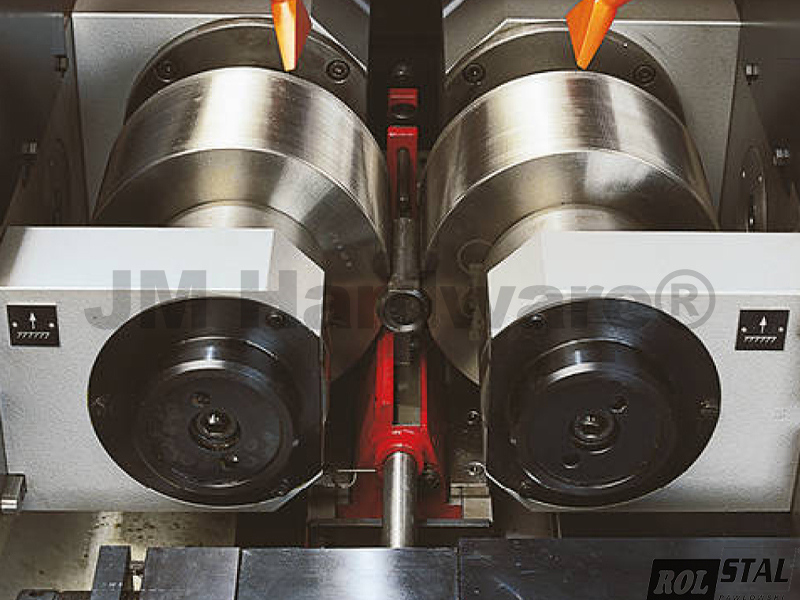

Thread Rolling:

Threads are rolled to enhance strength and prevent material weakening.

-

Heat Treatment:

Bolts are heat-treated to achieve the desired hardness and tensile strength.

-

Surface Treatment:

Coatings are applied to improve corrosion resistance and durability.

-

Final Inspection:

Each bolt undergoes rigorous testing and inspection to meet customer specifications.

Why Choose JM Hardware® as Your Foundation Anchor Bolt Manufacturer?

1.Custom Solutions: We offer tailored fasteners for specific construction needs, ensuring compatibility with your project requirements.

2.Wide Range of Products: From standard to high-strength and corrosion-resistant bolts, we offer an extensive selection of concrete bolts.

3.High-Quality Materials: Our bolts are made from high-quality materials for optimal strength, durability, and corrosion resistance.

4.Global Reach: We provide fasteners to construction projects around the world, ensuring timely delivery and availability.

5.Comprehensive Support: From product selection to post-delivery assistance, we provide end-to-end support for your concrete bolt needs.

6.Competitive Pricing: We offer high-quality bolts at competitive prices to fit your budget while maintaining exceptional performance.

Contact JM Hardware® for Foundation Anchor Bolt Solutions

Looking for a trusted foundation anchor bolt manufacturer for your next project? At JM Hardware®, we combine technical expertise, advanced manufacturing, and rigorous quality control to deliver reliable and durable anchor bolt solutions. Contact us today for a consultation or to request a custom solution. Trust JM Hardware® to anchor your success!