-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a trusted eye bolt manufacturer dedicated to producing durable, reliable, and high-quality eye bolts for industrial, construction, marine, and heavy-duty applications. Eye bolts are a critical fastener type, used primarily for lifting, rigging, and securing loads. With years of experience and advanced manufacturing capabilities, JM Hardware® delivers eye bolts that meet and exceed industry standards, offering exceptional performance across diverse industries.

What is an Eye Bolt?

Aneye bolt is a type of fastener featuring a loop (eye) at one end and a threaded shaft on the other. Its primary function is to serve as a connection point for lifting equipment, rigging systems, or tension cables. Eye bolts are essential in applications requiring secure and durable attachments under heavy loads, making them indispensable in industrial and commercial operations.

Types of Eye Bolts We Manufacture

At JM Hardware®, we manufacture a variety of eye bolts to suit diverse applications:

-

Forged Eye Bolts:

Made from one solid piece of steel, providing unmatched strength and durability for heavy loads.

-

Shoulder Eye Bolts:

Designed for angular loads and tension applications, preventing deformation under stress.

-

Plain Eye Bolts:

Ideal for vertical loads, commonly used in simple lifting and securing tasks.

-

Swivel Eye Bolts:

Rotating eye bolts that prevent tangling of attached cables or ropes, ideal for dynamic loads.

-

Lag Eye Bolts:

Featuring a screw-like thread, they are designed for wood or soft material installations.

-

Heavy-Duty Eye Bolts:

Built for extreme loads, often used in construction and industrial lifting applications.

-

Custom Eye Bolts:

Tailored to meet unique specifications, including size, material, and design.

Materials Used for Eye Bolts

We manufacture eye bolts using premium materials to ensure durability, strength, and resistance to environmental challenges. Our material options include:

-

Carbon Steel:

Offers excellent tensile strength, making it suitable for heavy-duty applications in controlled environments.

-

Stainless Steel (SS304, SS316):

Provides superior corrosion resistance, ideal for marine, chemical, and outdoor environments.

-

Alloy Steel:

Used in high-stress and high-temperature applications due to its exceptional strength and fatigue resistance.

-

Galvanized Steel:

Coated to resist rust and corrosion, perfect for outdoor and industrial settings.

-

Brass and Bronze

Non-sparking and corrosion-resistant, making them suitable for electrical and hazardous environments.

-

Titanium

Lightweight and resistant to extreme temperatures and corrosion, often used in aerospace and marine applications.

-

Duplex Stainless Steel:

Combines high strength with excellent resistance to chloride corrosion, perfect for coastal and offshore installations.

Surface Treatments for Enhanced Performance

To enhance durability, corrosion resistance, and aesthetics, we offer various surface finishes for our eye bolts:

-

Zinc Plating:

Offers moderate rust resistance and is commonly used in general-purpose applications.

-

Hot-Dip Galvanizing:

Provides superior protection against corrosion, ideal for outdoor applications.

-

Powder Coating:

Adds a durable, protective layer with color options for custom applications.

-

Electropolishing:

Provides a smooth, shiny finish and enhances corrosion resistance for stainless steel eye bolts.

-

Teflon Coating:

Non-stick and chemical-resistant, suitable for extreme environments.

-

Black Oxide Coating:

Adds a sleek black finish and light corrosion resistance, suitable for indoor or low-humidity environments.

-

Phosphate Coating:

Improves wear resistance and reduces friction in mechanical applications.

Applications of Eye Bolts

Eye bolts are versatile fasteners used in a wide variety of industries and applications:

-

Construction

Lifting and securing heavy components like beams, scaffolding, and equipment.

-

Oil & Gas

Securely anchoring equipment and cables in harsh, corrosive environments.

-

Industrial Equipment

Fastening, lifting, or tensioning components in machinery and heavy equipment.

-

Aerospace

Lightweight and high-strength eye bolts for securing sensitive equipment in high-stress environments.

-

Renewable Energy Energy

Fastening and lifting components in wind turbines and solar panel structures.

-

Marine Applications

Used in mooring, rigging, and lifting systems where corrosion resistance is essential.

-

Utilities

Used in power line installations, cable management, and pole attachments.

-

Transportation

Securing cargo, lifting heavy vehicle parts, and assembling rail or bridge components.

Grades and Standards for Eye Bolts

As a trusted eye bolt manufacturer, our products meet a variety of international standards and grades to ensure quality and reliability:

-

ISO 3266:

Covers dimensional and performance standards for lifting eye bolts.

-

DIN 580 (German Standard)

Common for forged eye bolts in industrial applications.

-

ASTM B30.26 (American Standard)

Focuses on lifting and rigging applications.

-

ASTM F541 (American Standard)

Specifications for forged eye bolts in heavy-duty applications.

-

BS 4278 (British Standard)

For general-purpose eye bolts with load ratings.

-

SAE J429

Standards for mechanical properties of alloy and carbon steel fasteners.

-

Custom Grades:

We also provide eye bolts manufactured to meet customer-specific requirements.

Quality Assurance and Testing Methods

At JM Hardware®, we follow stringent quality control measures to ensure that our eye bolts meet the highest safety and performance standards. Our testing methods include:

-

Tensile Testing:

Ensures that bolts can withstand high loads without failure.

-

Load Testing:

Confirms the safe working load (SWL) and breaking load of each bolt.

-

Corrosion Resistance Testing:

Simulates harsh environments to ensure durability in marine or outdoor applications.

-

Dimensional Accuracy Testing:

Verifies precise measurements to ensure compatibility with assembly components.

-

Impact Resistance Testing:

Tests the bolt’s ability to handle sudden shocks and stresses.

-

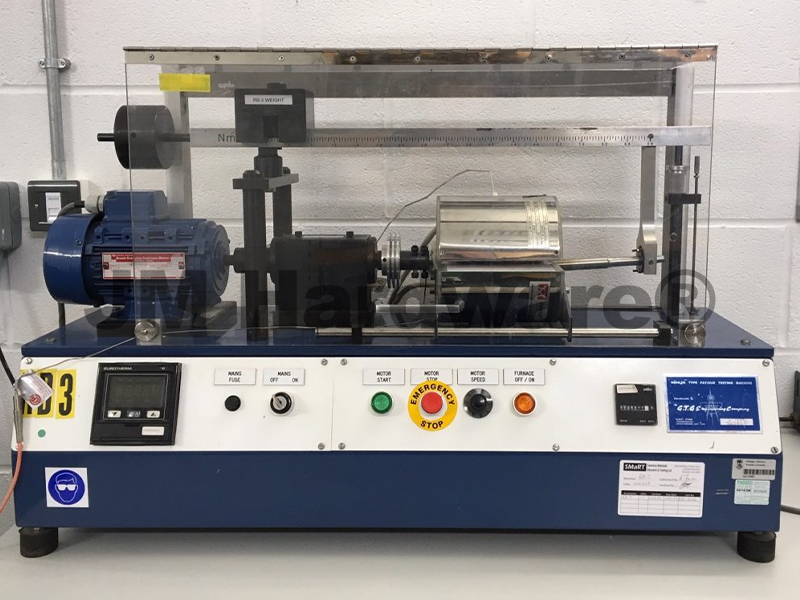

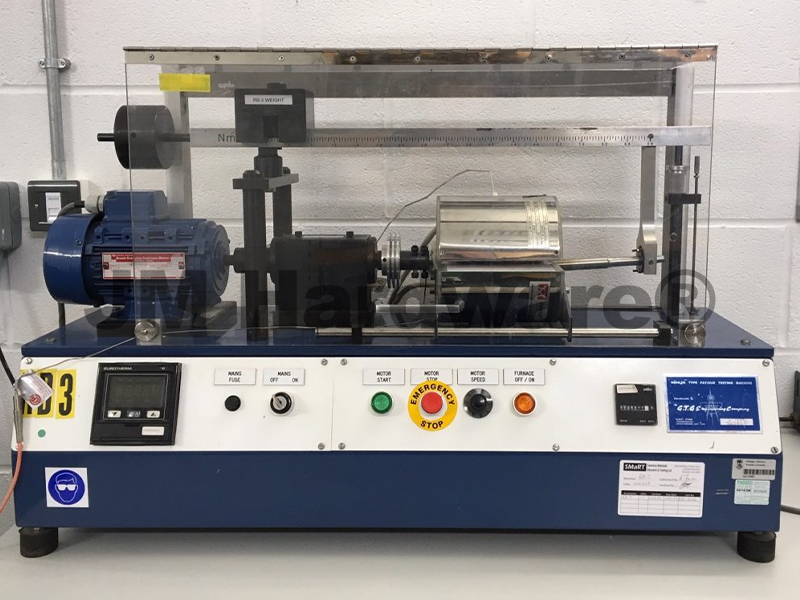

Fatigue Testing:

Evaluates performance under repeated load cycles to ensure long-term reliability.

-

Thread Integrity Testing:

Ensures smooth threading and proper alignment for easy installation.

Manufacturing Process of Eye Bolts

As a leading eye bolt manufacturer, our production process combines advanced technology and skilled craftsmanship:

-

Material Selection:

High-quality raw materials are chosen based on the application’s strength and environmental requirements.

-

Forging and Forming:

Eye bolts are forged or cold-formed to achieve the desired shape and strength.

-

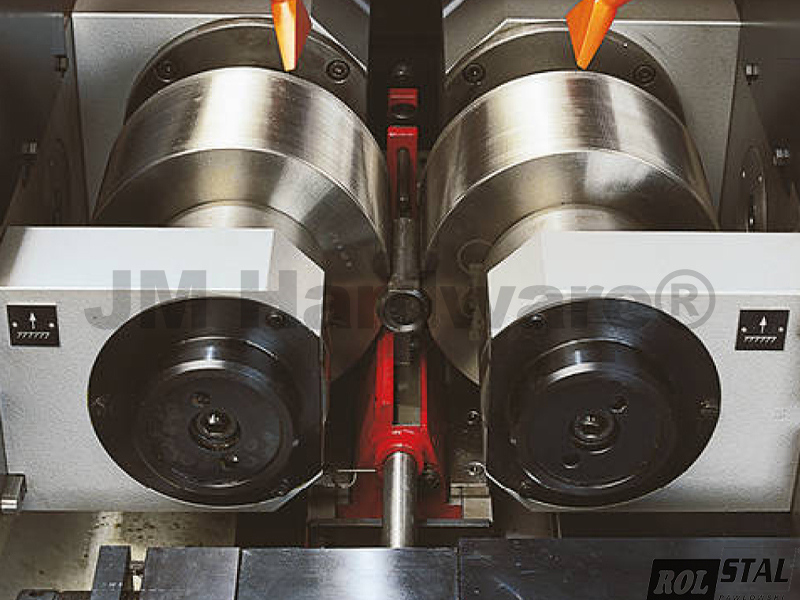

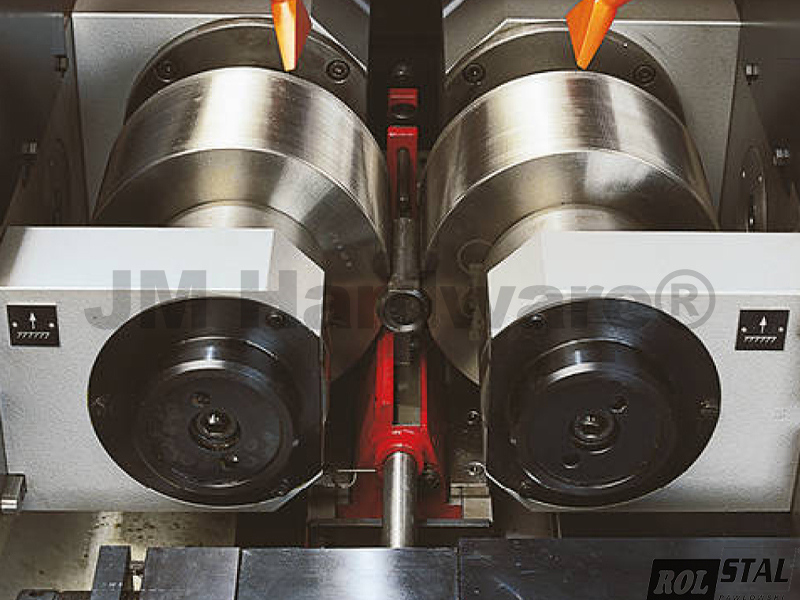

Thread Rolling:

Threads are rolled to ensure strength and precision, avoiding material loss compared to cutting.

-

Heat Treatment:

Heat treatment enhances the bolt’s tensile strength, hardness, and durability.

-

Surface Coating:

The bolts are treated with protective finishes to enhance their corrosion resistance and performance.

-

Quality Inspection:

Each bolt undergoes rigorous testing to ensure compliance with industry standards.

Why Choose JM Hardware® as Your Eye Bolt Manufacturer?

1.Extensive Product Range: We offer a wide variety of eye bolts to meet the needs of different industries.

2.Customization Options: Tailored eye bolts designed to meet your specific requirements, including size, material, and coatings.

3.High-Quality Standards: Our eye bolts meet or exceed international standards for safety, durability, and performance.

4.Global Supply: Reliable delivery to project sites worldwide, ensuring fast and efficient logistics.

5.Experienced Team: Decades of expertise in designing and manufacturing fasteners for critical applications.

6.Competitive Pricing: High-quality products at cost-effective prices, providing value without compromise.

Contact JM Hardware® for Eye Bolt Needs

Looking for a reliable eye bolt manufacturer? At JM Hardware®, we specialize in producing high-performance eye bolts for lifting, rigging, and securing applications. Contact us today to discuss your project requirements or request a quote. Trust JM Hardware® for precision-engineered fasteners that deliver unmatched quality and reliability!