-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a trusted Dyna bolt manufacturer, offering high-quality expansion bolts designed to provide reliable and secure fastening in concrete, brick, and masonry applications. With decades of expertise, we specialize in delivering standard and custom Dyna bolts that meet the demanding needs of construction, infrastructure, and industrial projects. Our comprehensive product offerings, advanced manufacturing capabilities, and strict quality assurance make us the preferred partner for global buyers.

What Are Dyna Bolts?

Dyna bolts, also known as expansion anchors, are heavy-duty fasteners designed for securing fixtures to solid materials like concrete, stone, or brick. Unlike regular bolts, Dyna bolts expand within a pre-drilled hole to create a strong grip, making them ideal for high-load applications. These bolts are commonly used in construction, industrial machinery, and infrastructure projects due to their exceptional holding power and versatility.

Key Features of Our Dyna Bolts

-

Secure Expansion Mechanism:

Provides a firm grip in concrete and masonry, ensuring stability even under heavy loads.

-

Variety of Sizes:

Available in a range of diameters and lengths to suit different project requirements.

-

Corrosion Resistance:

Designed with materials and coatings to withstand harsh environmental conditions.

-

Easy Installation:

Simple to use with pre-drilled holes, reducing installation time and labor costs.

-

Custom Solutions:

We offer tailor-made Dyna bolts for unique applications, including non-standard sizes and materials.

Materials Used in Dyna Bolt Manufacturing

As a professional Dyna bolt manufacturer, we offer bolts in a variety of materials to ensure performance and longevity:

-

Carbon Steel:

Ideal for general-purpose applications where cost-efficiency is key.

-

Stainless Steel (SS304, SS316):

Known for excellent corrosion resistance, especially in outdoor or marine environments.

-

Alloy Steel:

Offers superior strength and is suitable for heavy-duty industrial use.

-

Galvanized Steel:

Provides enhanced corrosion protection for outdoor and structural applications.

-

Brass:

Commonly used in applications requiring non-magnetic properties or resistance to certain chemicals.

-

Duplex Stainless Steel:

Combines strength and corrosion resistance, making it ideal for challenging environments.

Surface Finishes for Dyna Bolts

To enhance performance and durability, we provide a variety of surface treatments for Dyna bolts:

-

Zinc Plating:

Provides basic corrosion resistance for indoor and low-humidity applications.

-

Hot-Dip Galvanizing:

Offers superior rust protection, ideal for outdoor and coastal environments.

-

Powder Coating:

Ensures aesthetic appeal while adding a layer of rust protection.

-

Epoxy Coating:

Adds a durable layer of protection against chemical exposure and harsh environments.

-

Teflon Coating:(for stainless steel):

Offers a non-stick, corrosion-resistant surface for specialized applications.

Applications of Dyna Bolts

As a specialized Dyna bolt manufacturer, we cater to a wide range of industries and applications:

-

Construction

·Securing structural components like beams, brackets, and frames.

·Anchoring heavy equipment and machinery. -

Infrastructure

·Fixing guardrails, signposts, and fences in highways and bridges.

·Attaching utility structures like poles and towers to concrete bases. -

Industrial Projects

·Anchoring machinery and equipment to factory floors.

·Installing pipelines and support brackets in industrial facilities. -

HVAC Systems

Fixing air conditioning units and duct systems to walls and ceilings.

-

Solar Energy

Mounting solar panels and support structures to concrete foundations.

-

Marine Applications

Securing components in docks, piers, and offshore platforms.

-

Residential Projects

Installing balustrades, railings, and decorative fixtures.

Standards and Certifications

As a leading Dyna bolt manufacturer, all our products comply with international standards to ensure reliability and safety:

-

ISO 9001:

Ensures strict quality management processes.

-

DIN (Deutsches Institut für Normung):

European standards for dimensional accuracy and performance.

-

ASTM Standards:

Guarantees compliance with mechanical and material property requirements.

-

BS (British Standards):

Ensures suitability for infrastructure and structural applications.

-

JIS (Japanese Industrial Standards):

Focuses on precision manufacturing for industrial needs.

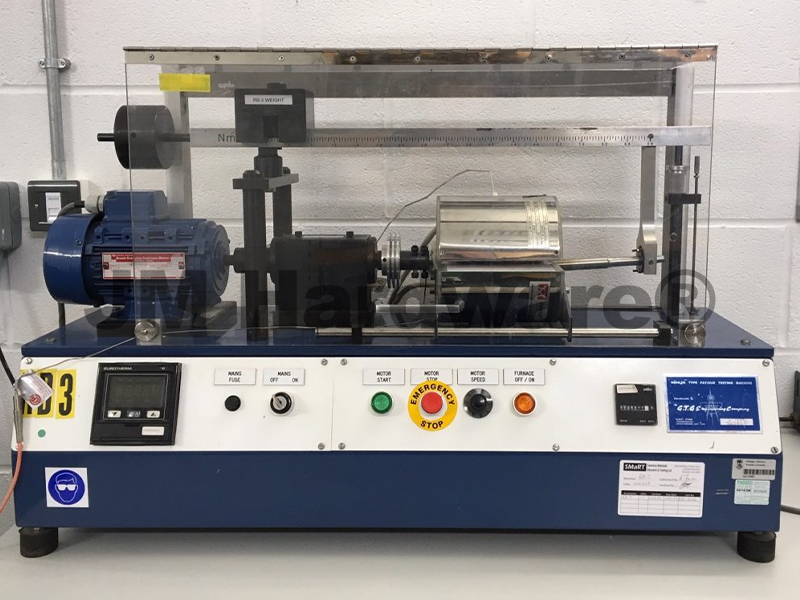

Testing and Quality Assurance

We follow rigorous quality control measures to ensure every Dyna bolt meets the highest standards for performance and safety. Our testing methods include:

-

Tensile Testing:

Ensures that bolts can withstand high loads without failure.

-

Pull-Out Strength Testing:

Verifies the holding capacity of the bolt in different materials.

-

Corrosion Resistance Testing:

Measures the fastener’s ability to withstand environmental challenges, such as salt spray.

-

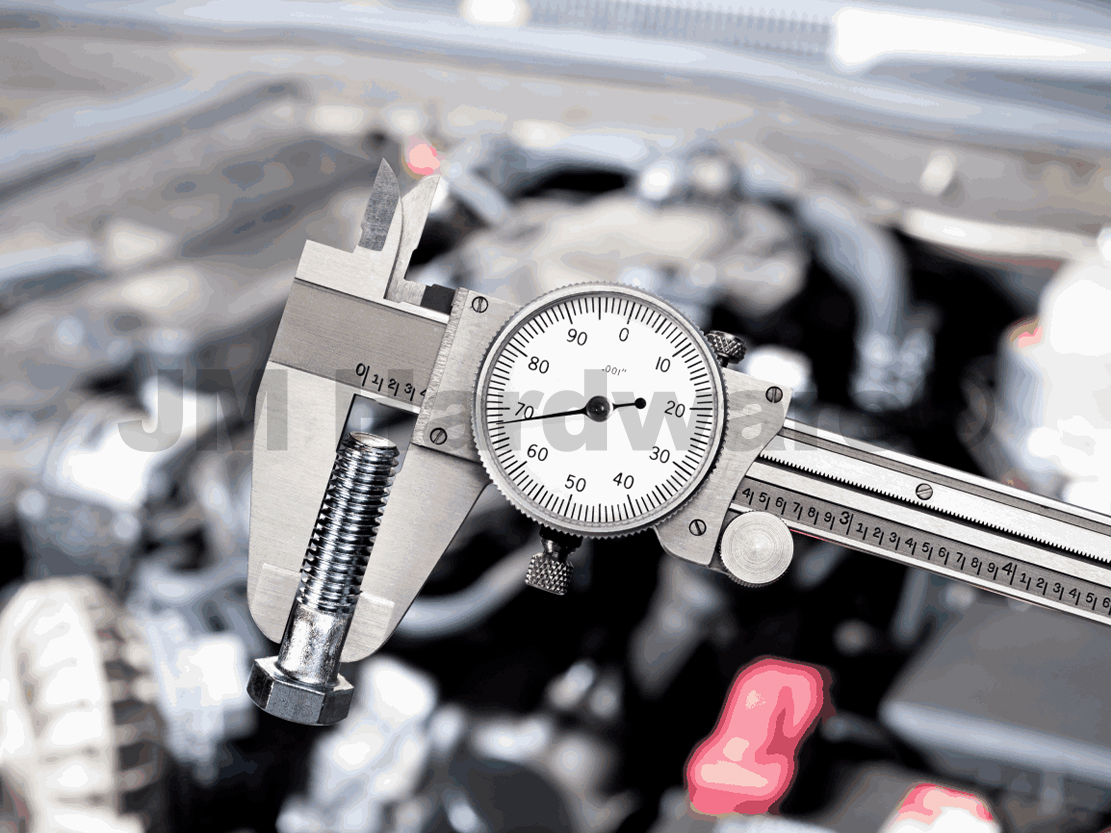

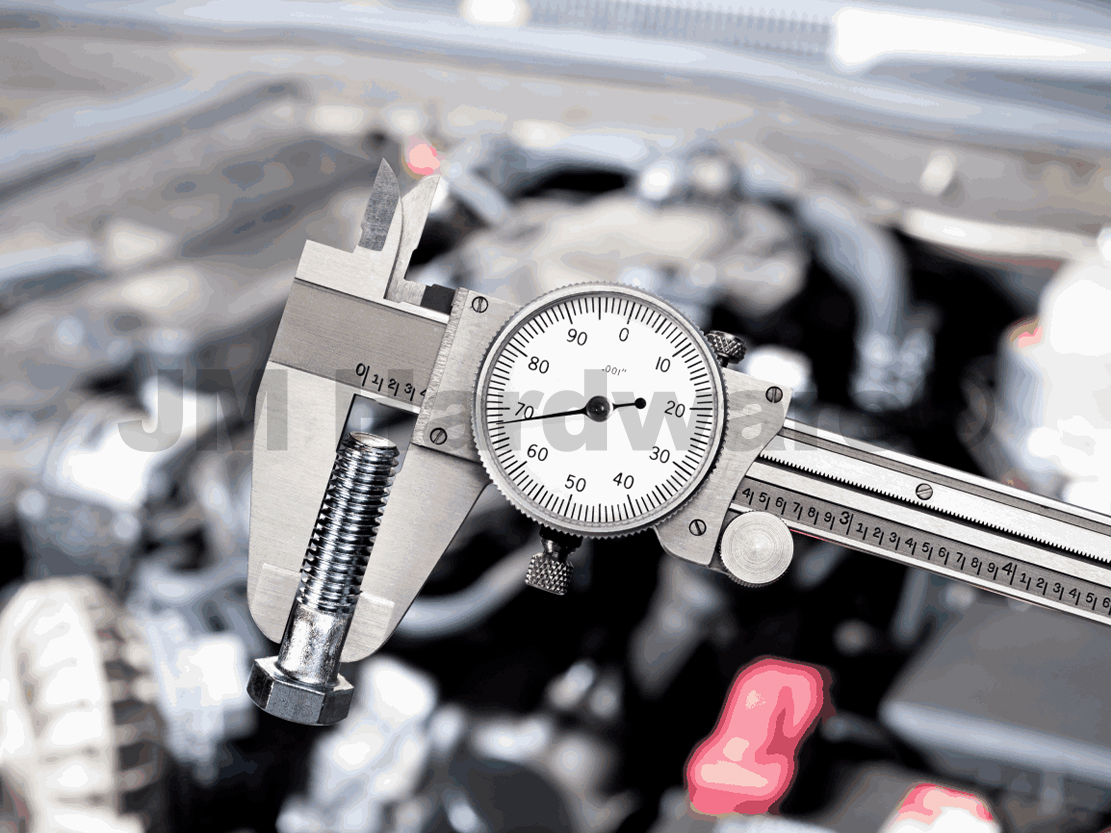

Dimensional Accuracy Testing:

Confirms precision in size, thread quality, and expansion mechanisms.

-

Impact Resistance Testing:

Evaluates performance under sudden impacts or vibrations.

-

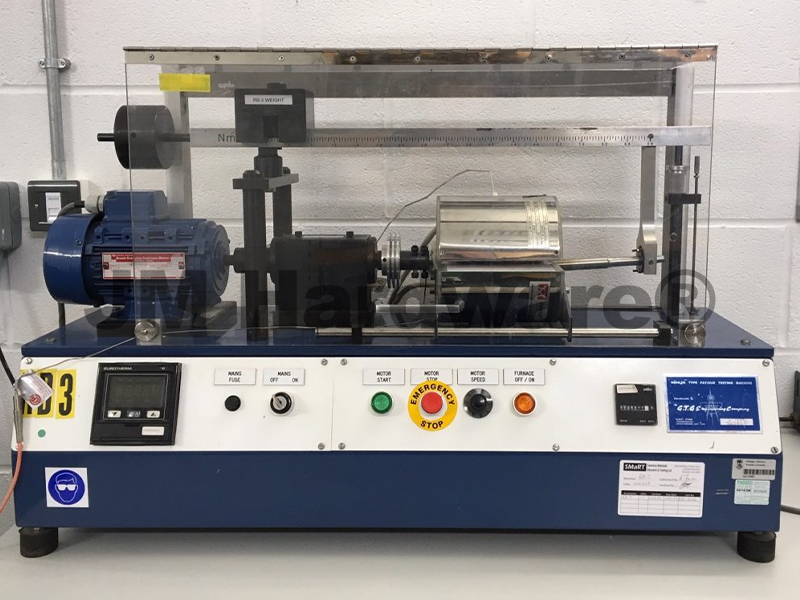

Fatigue Testing:

Ensures long-term durability under repeated loads.

Production Process for Dyna Bolts

Our advanced manufacturing facilities and skilled workforce allow us to produce high-quality Dyna bolts efficiently. The production process includes:

-

Material Selection:

We source premium raw materials to ensure strength and performance.

-

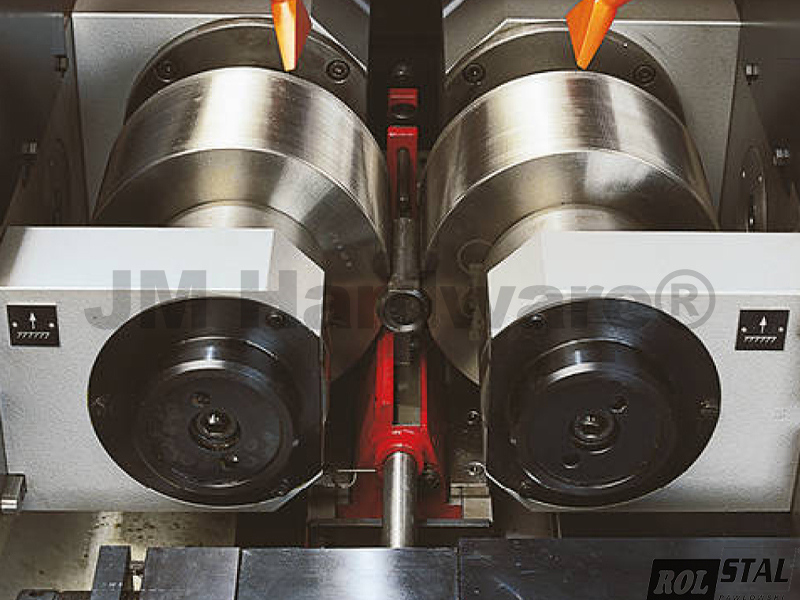

Precision Forging:

Creates the bolt head and expansion sleeve with high accuracy.

-

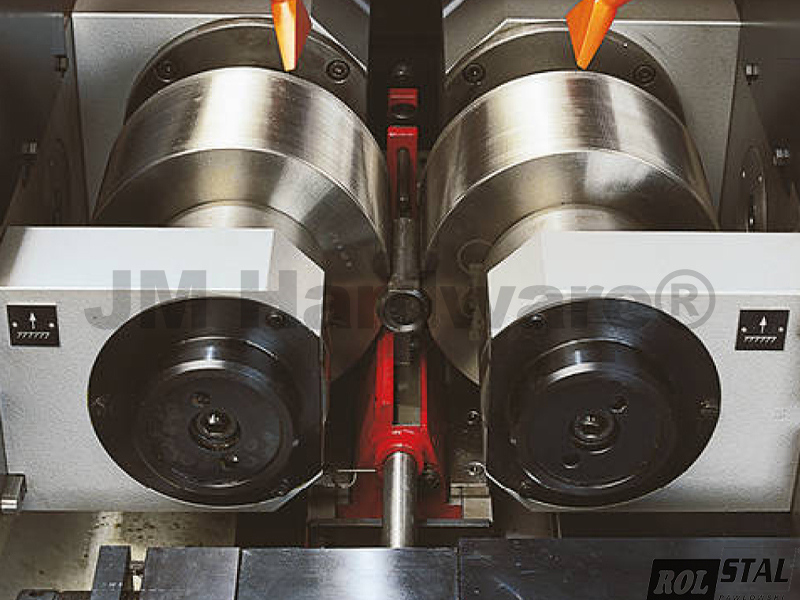

Thread Rolling:

Forms precise threads for secure fastening.

-

Heat Treatment:

4.Enhances the bolt’s strength and durability.

-

Surface Coating:

Applies coatings to improve corrosion resistance and aesthetics.

-

Quality Inspection:

Every bolt undergoes rigorous testing to ensure compliance with specifications.

Why Choose JM Hardware® as Your Dyna Bolt Manufacturer?

1.Comprehensive Product Range: We offer a wide variety of Dyna bolts for all applications.

2.Custom Manufacturing: Tailored solutions for unique project requirements.

3.High-Quality Materials: Premium materials ensure durability and performance.

4.Advanced Production Facilities: State-of-the-art equipment for precision manufacturing.

5.Global Delivery: Reliable shipping to meet tight project timelines worldwide.

6.Competitive Pricing: Affordable solutions without compromising on quality.

7.Expert Support: Dedicated team providing technical assistance and recommendations.

Contact JM Hardware® for Dyna Bolt Solutions

As a trusted Dyna bolt manufacturer, we are committed to delivering high-quality fasteners that meet your project’s specific needs. Whether you require standard expansion anchors or custom solutions, JM Hardware® has the expertise and resources to provide the best fastening products. Contact us today to learn more about our products or request a quote. Let us help you build with confidence!