-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing heavy hex structural bolts designed for demanding applications in construction, infrastructure, and industrial projects. As a leading heavy hex structural bolt manufacturer, we provide precision-engineered fasteners that meet rigorous performance requirements for strength, durability, and reliability. With our advanced manufacturing capabilities, wide material options, and strict quality standards, we are the trusted partner for B2B buyers worldwide.

Key Features of Heavy Hex Structural Bolts

Hex cap bolts are versatile fasteners designed with a hexagonal head and a threaded body, used for secure and reliable connections in a variety of industrial applications. These bolts are typically used with nuts or directly threaded into tapped holes for fastening components. Hex cap bolts are highly valued for their durability, strength, and ability to withstand high loads and environmental challenges.

Why Choose JM Hardware® as Your Hex Cap Bolt Manufacturer?

1.Increased Head Size: Provides greater surface contact for secure fastening.

2.High Tensile Strength: Engineered to handle extreme loads and stress in structural applications.

3.Corrosion Resistance: Available in materials and coatings designed to withstand harsh environments.

4.Compliance with Industry Standards: Manufactured to meet international standards for safety and reliability.

5.Precision Threads: Ensures seamless fit and proper load transfer in structural assemblies.

Materials for Heavy Hex Structural Bolts

As a professional heavy hex structural bolt manufacturer, we offer bolts in a variety of materials to suit specific project requirements:

-

Carbon Steel:

Provides excellent strength and durability for general structural applications.

-

Alloy Steel:

Suitable for high-stress environments due to its superior tensile and yield strength.

-

Stainless Steel (SS304, SS316):

Corrosion-resistant and ideal for marine, coastal, and high-moisture environments.

-

Quenched and Tempered Steel:

Heat-treated for exceptional mechanical properties in demanding applications.

-

Weathering Steel:

Offers natural rust resistance for outdoor structures, eliminating the need for additional coatings.

-

Duplex Stainless Steel:

Combines high strength with superior resistance to chloride-induced corrosion, perfect for offshore and chemical projects.

Surface Finishes for Enhanced Durability

To ensure long-term performance and protection, we provide a variety of surface treatments for our heavy hex structural bolts:

-

Zinc Plating:

Cost-effective rust protection for indoor or low-exposure environments.

-

Hot-Dip Galvanizing:

Provides exceptional corrosion resistance, especially for outdoor and marine projects.

-

Teflon Coating:

Chemical-resistant and ideal for industrial environments.

-

Black Oxide Coating:

Adds a sleek finish with moderate corrosion resistance.

-

Powder Coating:

Provides a durable, protective layer with customizable colors for aesthetic and functional purposes.

-

Epoxy Coating:

Improves lubrication and corrosion resistance, commonly used in automotive and machinery industries.

Grades of Heavy Hex Structural Bolts

We manufacture heavy hex structural bolts in various grades to meet the performance requirements of different industries. Common grades include:

1.ASTM A325: High-strength bolts designed for structural steel-to-steel connections.

2.ASTM A490: Provides even higher strength for demanding structural applications.

3.Grade 8.8 and 10.9: Medium- to high-strength bolts suitable for industrial machinery and construction.

4.ASTM F3125: Covers high-strength structural bolts, including both A325 and A490.

5.Grade 5 and Grade 8: For moderate to heavy-duty structural applications.

BS 3692: Covers metric bolts used in steel structures and engineering projects

Standards for Heavy Hex Structural Bolts

Our heavy hex structural bolts are manufactured to meet or exceed the following international standards:

-

ISO (International Organization for Standardization)

International standards for strength and mechanical properties.

-

DIN (Deutsches Institut für Normung)

European standards for precision and performance.

-

ASTM(American Society for Testing and Materials)

Defines mechanical and material properties.

-

SAE (Society of Automotive Engineers)

Standards for automotive and machinery applications.

-

BS (British Standards)

Standards for industrial and construction fasteners.

-

JIS

The standards are used for industrial activities in Japan, coordinated by the Japanese Industrial Standards Committee (JISC)

Applications of Heavy Hex Structural Bolts

Heavy hex structural bolts are essential in critical construction and infrastructure projects where strength and durability are non-negotiable. Some common applications include:

-

Bridge Construction

Bolts secure large structural components, such as girders and trusses, ensuring the stability of the entire structure.

-

Steel Buildings

Used in the assembly of beams, columns, and other steel framework elements.

-

Power Plants

Critical for securing heavy machinery and structural components in energy facilities..

-

Wind Turbines

Withstand extreme loads and environmental conditions in renewable energy projects.

-

Transmission Towers

Securely fasten tower structures for power and telecom lines.

-

Heavy Equipment

Used in the assembly of industrial machinery and mining equipment.

-

Oil & Gas Industry

Suitable for offshore rigs, refineries, and pipelines due to their strength and corrosion resistance.

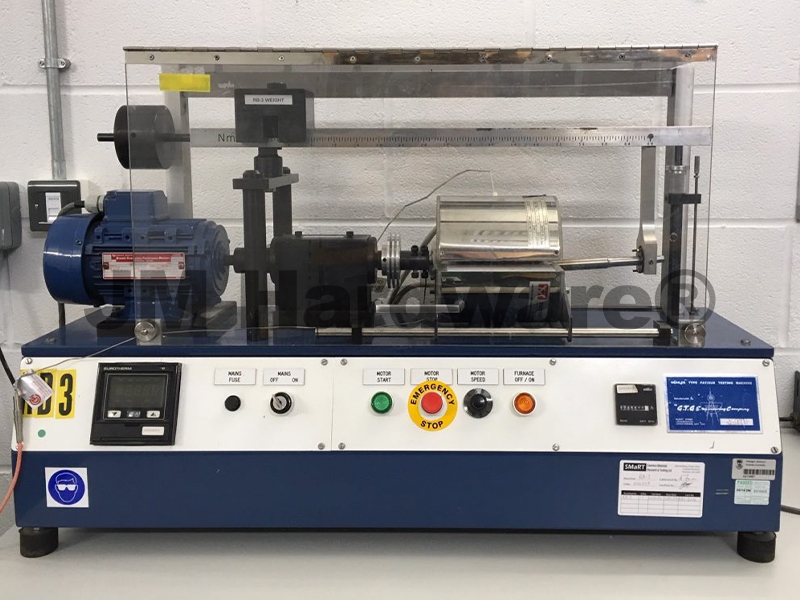

Testing Methods for Heavy Hex Structural Bolts

As a reputable heavy hex structural bolt manufacturer, we ensure that every bolt meets the highest standards of quality through rigorous testing:

-

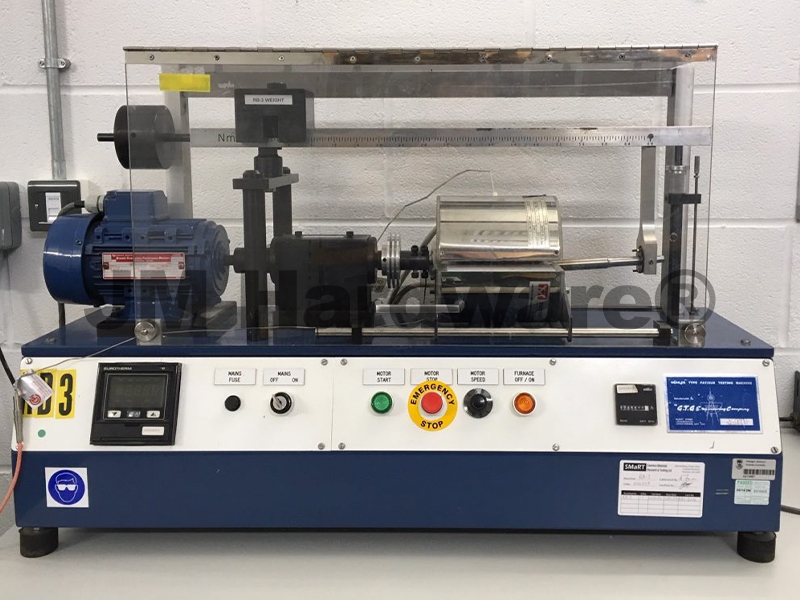

Tensile Testing:

Ensures bolts can handle high loads and stress.

-

Salt Spray Testing

Confirms corrosion resistance in harsh environments.

-

Corrosion Resistance Testing:

Simulates harsh environments to assess durability.

-

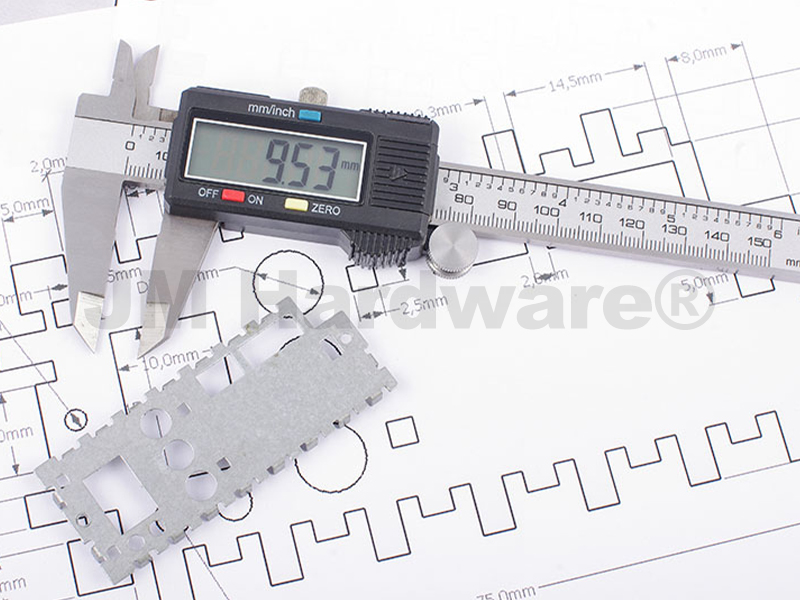

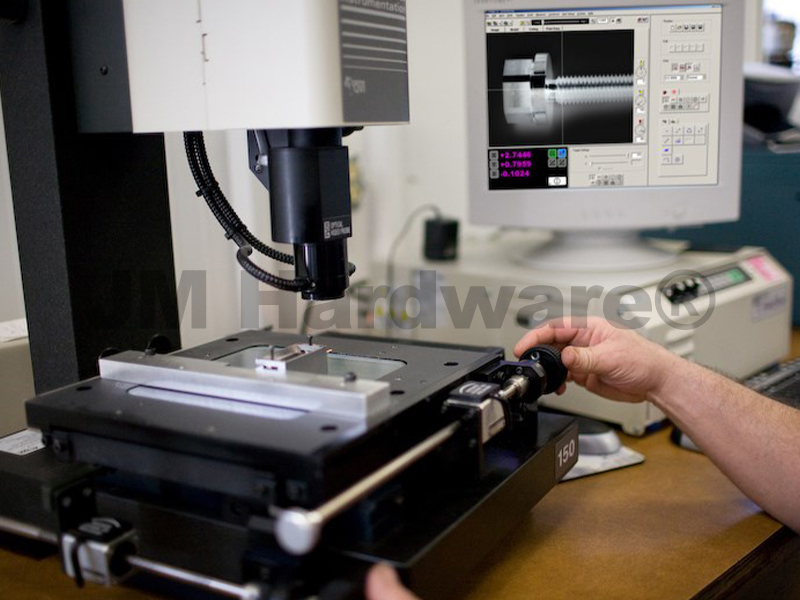

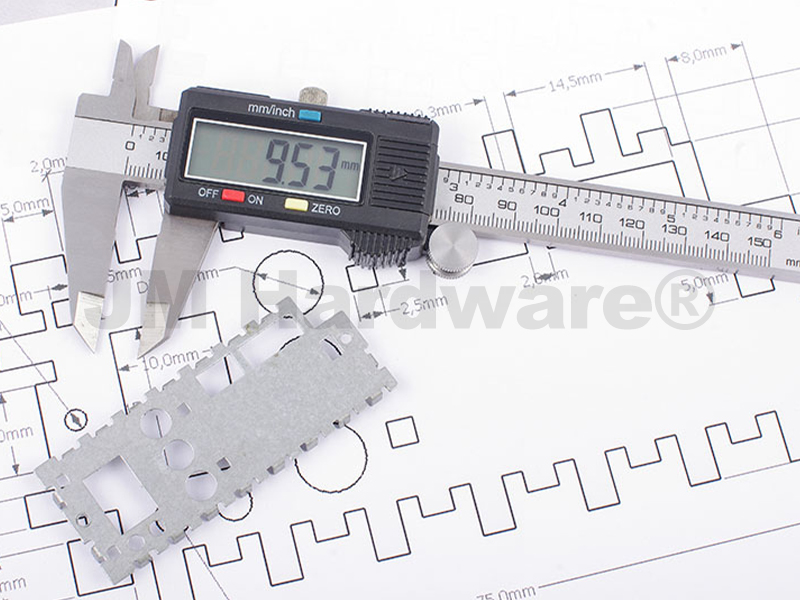

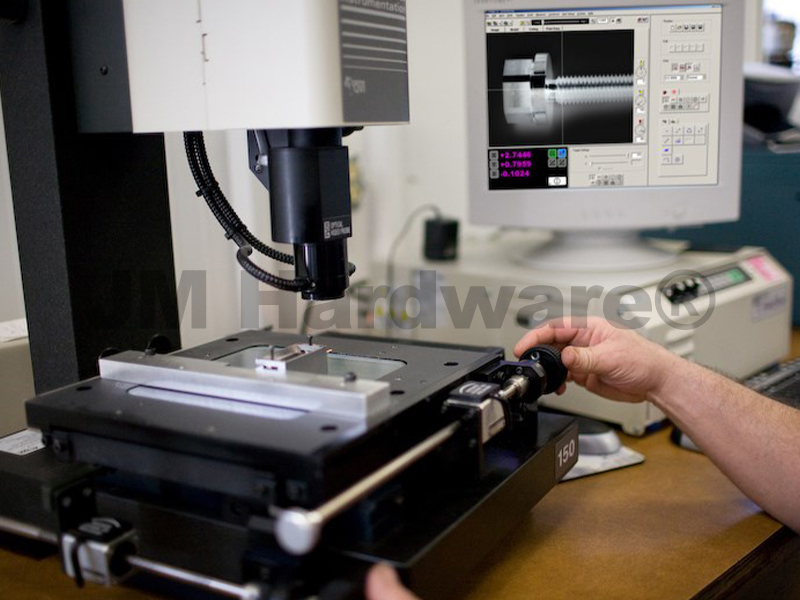

Dimensional Accuracy Testing:

Ensures precise measurements for seamless installation.

-

Impact Resistance Testing:

Evaluates bolt performance under dynamic loads or impacts.

-

Hardness Testing:

Verifies the material's ability to resist deformation under stress.

-

Vibration Testing: Ensures bolts remain secure under dynamic loads and high vibrations.

Production Process of Heavy Hex Structural Bolts

Our advanced manufacturing processes ensure precision and quality at every stage:

-

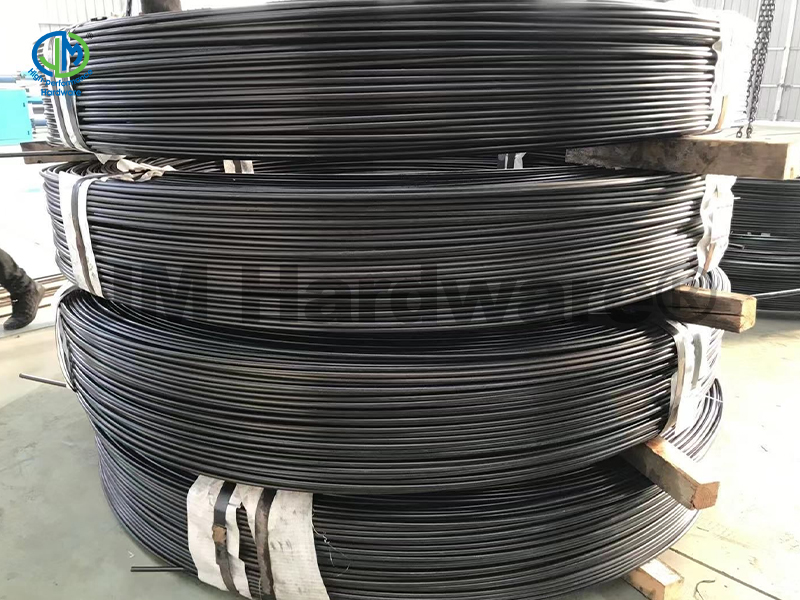

Raw Material Selection:

Premium materials are sourced to meet strength and corrosion resistance requirements.

-

Forging:

The bolt heads are forged to ensure uniformity and structural integrity.

-

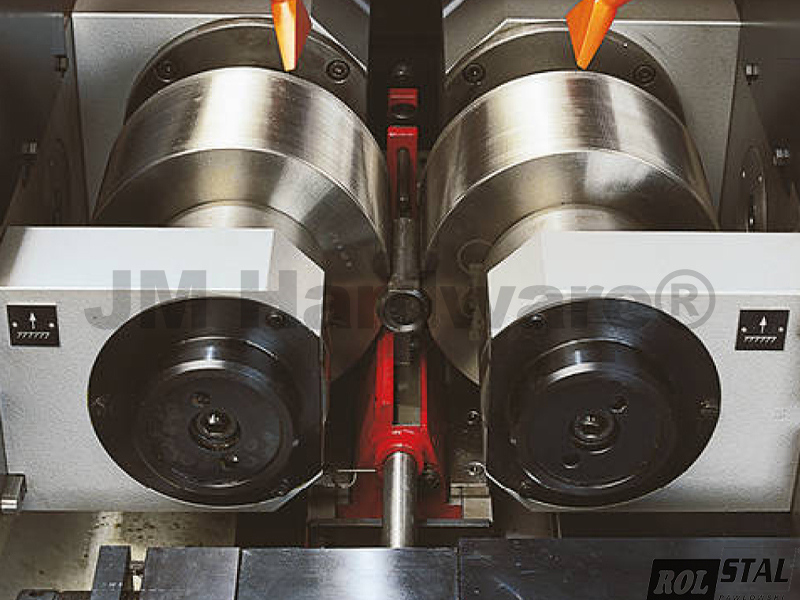

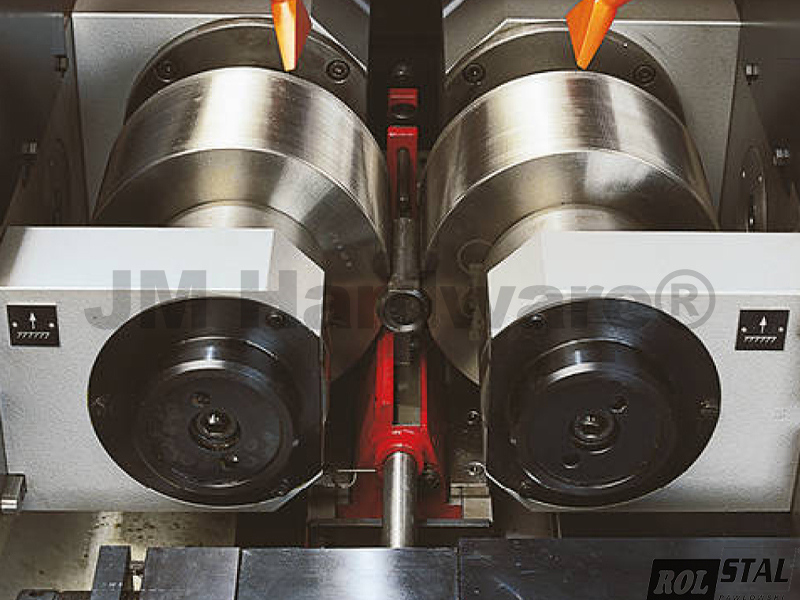

Thread Rolling:

Threads are rolled to enhance strength and prevent material weakening.

-

Heat Treatment:

Bolts are heat-treated to achieve the desired hardness and tensile strength.

-

Surface Treatment:

Coatings are applied to improve corrosion resistance and durability.

-

Final Inspection:

Each bolt undergoes rigorous testing and inspection to meet customer specifications.

Why Choose JM Hardware® as Your Heavy Hex Structural Bolt Manufacturer?

1.Extensive Product Range: Offering a variety of materials, grades, and finishes to meet project-specific needs.

2.Custom Manufacturing: Tailored solutions for unique applications, including non-standard sizes and finishes. 3.Global Delivery: Efficient logistics ensure fast and reliable delivery to projects worldwide.

4.Advanced Facilities: State-of-the-art manufacturing and testing equipment ensure precision and quality.

5.Compliance with Standards: Bolts manufactured to meet ASTM, DIN, ISO, and other global standards.

6.Competitive Pricing: High-quality bolts at cost-effective rates for large-scale projects.

7.Expert Support: A dedicated team of professionals ready to assist with product selection and custom solutions.

Contact JM Hardware® for Heavy Hex Structural Bolts

Looking for a reliable heavy hex structural bolt manufacturer? JM Hardware® is your trusted partner for high-strength fasteners. Contact us today to discuss your project requirements or request a quote. Let us provide you with the best fastener solutions to ensure the success of your structural projects!