-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing high-quality guardrail bolts, tailored for safety-critical applications in highway, bridge, and infrastructure projects. As a trusted guardrail bolt manufacturer, we provide a wide range of fasteners designed to meet the stringent requirements of the transportation and construction industries. Whether it’s for securing guardrails, crash barriers, or other structural components, our bolts are engineered for strength, durability, and long-lasting performance.

Why Choose JM Hardware® as Your Guardrail Bolt Manufacturer?

1.Comprehensive Product Range: We supply a wide variety of guardrail bolts, including hex bolts, carriage bolts, and custom-designed bolts for specific guardrail systems.

2.Custom Solutions: With our in-house design and manufacturing capabilities, we can produce bolts in non-standard sizes, materials, and finishes to meet unique project requirements.

3.Unmatched Durability: Our guardrail bolts are built to withstand harsh weather, heavy loads, and high vibrations, ensuring long-term safety and reliability.

4.Global Reach: With years of experience as a guardrail bolt manufacturer, we’ve supplied products to major infrastructure projects worldwide, including highways, bridges, and urban transportation systems.

5.Strict Quality Standards: Our bolts undergo rigorous testing to ensure compliance with international standards, providing confidence and peace of mind to our customers.

Comprehensive Guardrail Bolt Solutions

We offer a full line of fasteners designed specifically for guardrail applications, including

-

Hex Bolts:

Commonly used to fasten guardrail panels to posts, ensuring a strong and secure connection.

-

Carriage Bolts:

Perfect for guardrail assembly, with a smooth head that prevents tampering and enhances safety.

-

Shear Bolts:

Designed to protect structural components by absorbing impacts in crash scenarios.

-

Anchor Bolts:

Used for securing guardrails to concrete foundations or bridge structures.

-

Custom Bolts:

Specially designed to meet non-standard requirements or specific guardrail system designs.

Additionally, we provide a full range of complementary fasteners, such as nuts, washers, and spacers, to ensure seamless installation and secure connections.

Materials Used for Guardrail Bolts

Guardrails are exposed to extreme environmental conditions, including rain, snow, salt, and heavy traffic. To address these challenges, we manufacture our guardrail bolts from high-performance materials, including:

-

Carbon Steel:

Strong and cost-effective, suitable for standard applications.

-

Stainless Steel (SS304, SS316):

Provides excellent corrosion resistance, making it ideal for coastal highways and bridges.

-

High-Strength Alloy Steel:

Designed for heavy-duty applications where high tensile strength is critical.

-

Galvanized Steel:

Coated to resist rust and corrosion, perfect for outdoor and industrial settings.

-

Duplex Stainless Steel:

Combines high strength with excellent resistance to chloride corrosion, perfect for coastal and offshore installations.

Surface Finishes for Enhanced Durability

To ensure long-lasting performance in harsh environments, our guardrail bolts come with a variety of surface finishes, including:

-

Zinc Plating:

Cost-effective rust protection for indoor or low-exposure environments.

-

Hot-Dip Galvanizing:

Provides exceptional corrosion resistance, meeting the requirements of highway and bridge projects.

-

Powder Coating:

Offers additional corrosion resistance and can be customized in different colors for specific applications.

-

Teflon Coating:

Adds chemical resistance and ensures smooth installation.

-

Epoxy Coating:

Protects bolts from chemical exposure and extreme weather conditions.

Applications of Guardrail Bolts

As a leading guardrail bolt manufacturer, we supply fasteners for a wide range of safety-critical and infrastructure projects, including:

-

Highway Guardrails

Fastening guardrail panels, posts, and crash barriers along highways and roads.

-

Bridge Structures

Securing railings and protective barriers on bridges to enhance safety.

-

Crash Barriers

Providing impact-resistant connections in high-traffic and high-speed areas.

-

Urban Railings

Fasteners for protective railings in urban and pedestrian areas.

-

Tunnels and Overpasses

Bolts used in securing barriers and guardrails in confined or elevated environments.

-

Marine and Coastal Roads

Corrosion-resistant bolts for infrastructure exposed to saltwater environments.

-

Temporary Barriers

Fasteners for portable and movable guardrail systems used in construction zones.

Standards for Guardrail Bolts

As a trusted eye bolt manufacturer, our products meet a variety of international standards and grades to ensure quality and reliability:

-

ISO 898

Standards for mechanical properties of bolts.

-

DIN931 & 933

Specifications for hex bolts used in infrastructure projects.

-

ASTM A325 & A490

For structural bolts used in highway and bridge applications.

-

BS EN 14399

Standards for high-strength structural bolts for preloading.

-

JIS B1189

Japanese standards for bolt performance in guardrail systems.

Rigorous Testing for Quality Assurance

To ensure the highest level of safety and performance, our guardrail bolts are subjected to rigorous testing and inspection. Key tests include:

-

Tensile Testing:

Ensures bolts can handle high loads and stress.

-

Vibration Testing:

Ensures bolts maintain their integrity under constant vibration from heavy traffic.

-

Corrosion Resistance Testing:

Verifies durability in salt spray and extreme weather conditions.

-

Dimensional Accuracy Testing:

Confirms precise dimensions and thread quality for seamless installation.

-

Impact Resistance Testing:

Validates performance in crash and high-impact scenarios.

-

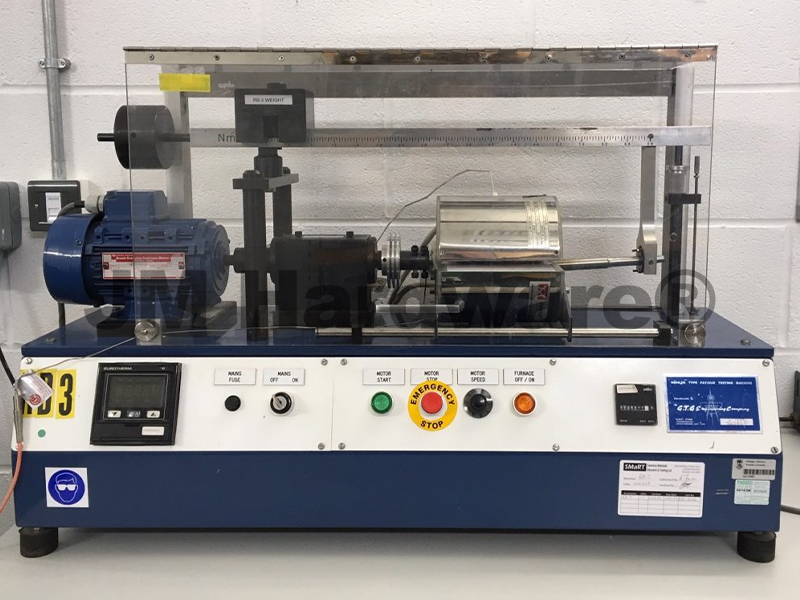

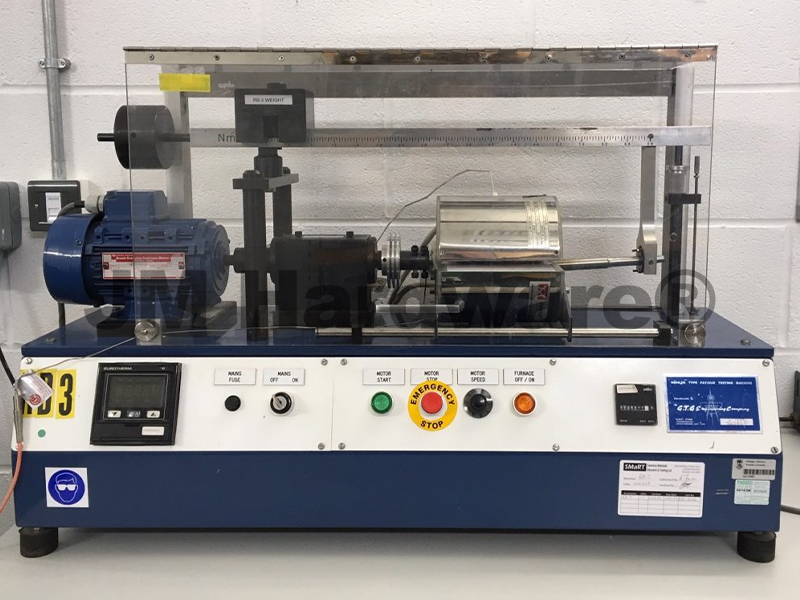

Fatigue Testing:

Assesses long-term durability in dynamic load conditions.

Production Process for Guardrail Bolts

As a trusted guardrail bolt manufacturer, we utilize advanced production techniques to ensure consistent quality and performance:

-

Material Selection:

High-grade raw materials are carefully chosen to meet the specific strength and corrosion resistance requirements of guardrail bolts.

-

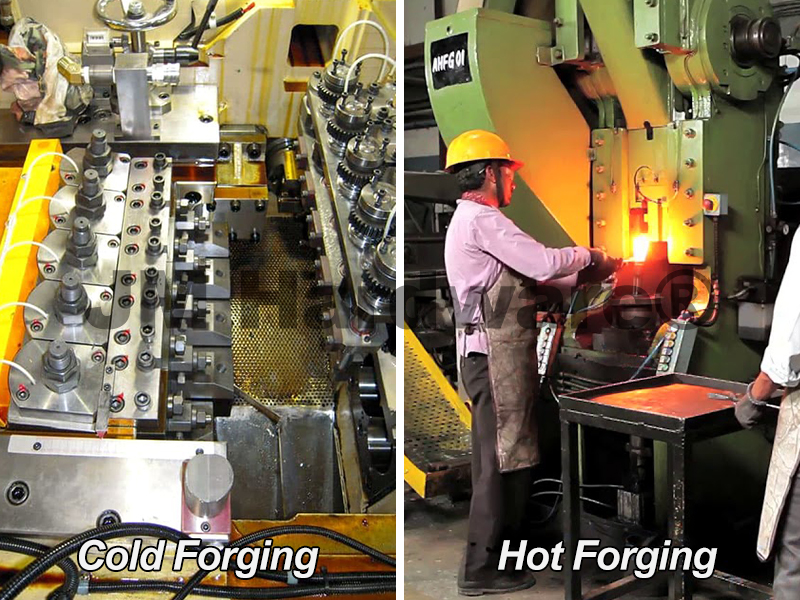

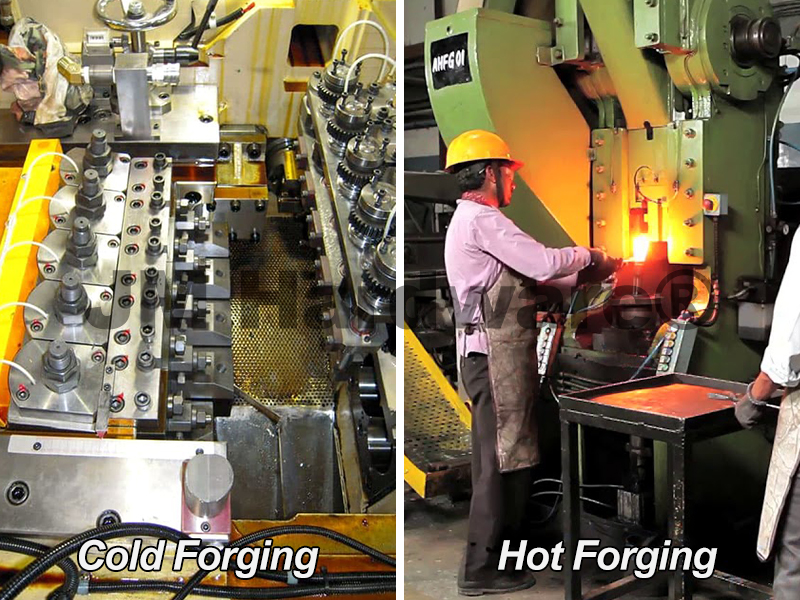

Cold and Hot Forging:

Forging processes create bolts with superior mechanical properties and dimensional accuracy.

-

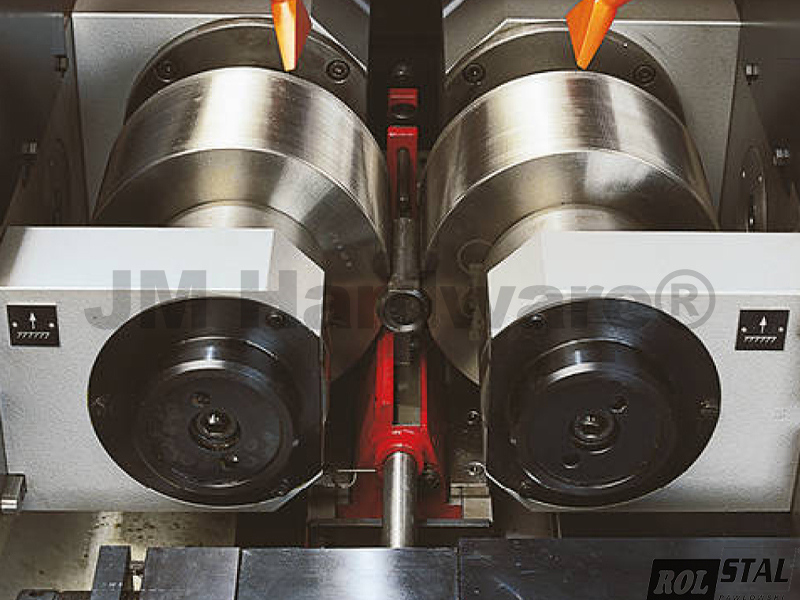

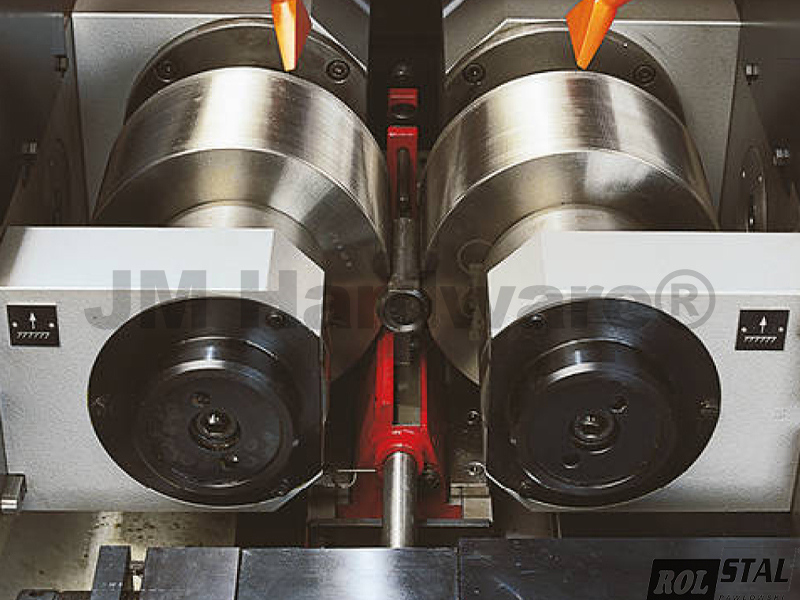

Thread Rolling:

Threads are rolled to enhance strength and prevent material weakening.

-

Heat Treatment:

Bolts are heat-treated to achieve the desired hardness and tensile strength.

-

Surface Coating:

Protective coatings are applied to improve corrosion resistance and durability.

-

Quality Control:

Each bolt undergoes comprehensive testing to ensure compliance with international standards.

Customized Solutions for Guardrail Bolts

We understand that each project has unique requirements. That’s why JM Hardware® offers custom guardrail bolt solutions, including:

- Non-standard sizes and dimensions.

- Custom coatings for enhanced corrosion resistance.

- Pre-assembled kits for easier installation on-site.

- Packaging tailored to project-specific logistics.

Why JM Hardware® is Your Best Choice for Guardrail Bolts

1,Extensive Industry Experience: Decades of expertise as a guardrail bolt manufacturerfor infrastructure projects worldwide.

2.Wide Product Range: From standard hex bolts to custom solutions, we cover all your needs.

3.Global Supply Chain: Reliable delivery to any location, ensuring your projects stay on schedule.

4.Advanced Manufacturing: State-of-the-art facilities produce bolts with unmatched precision and durability.

5.Commitment to Quality: Every bolt meets strict safety and performance standards.

6.Customer-Centric Approach: We offer tailored solutions and dedicated support for your project.

Contact JM Hardware® for High-Quality Guardrail Bolts

Looking for a reliable guardrail bolt manufacturer? JM Hardware® delivers durable, high-performance bolts for your highway, bridge, and safety barrier projects. Contact us today to discuss your requirements or request a custom solution. Partner with us to ensure safety, reliability, and success in every project!