-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

Fasteners and Hardware for Tower and Pole Line Projects

At JM Hardware®, we provide comprehensive fastener and hardware solutions specifically designed for tower and pole line construction and maintenance. Whether it’s for transmission towers, utility poles, communication towers, or lighting poles, our high-quality fasteners and hardware ensure reliability, safety, and long-term durability. These critical structures demand robust and precision-engineered components to withstand extreme environmental conditions, heavy loads, and vibrations. Our extensive product range and customization capabilities make us a trusted partner for tower and pole line projects worldwide.

Comprehensive Hardware Solutions for Tower and Pole Line Projects

We offer a wide variety of fasteners and hardware specifically engineered for tower and pole line applications:

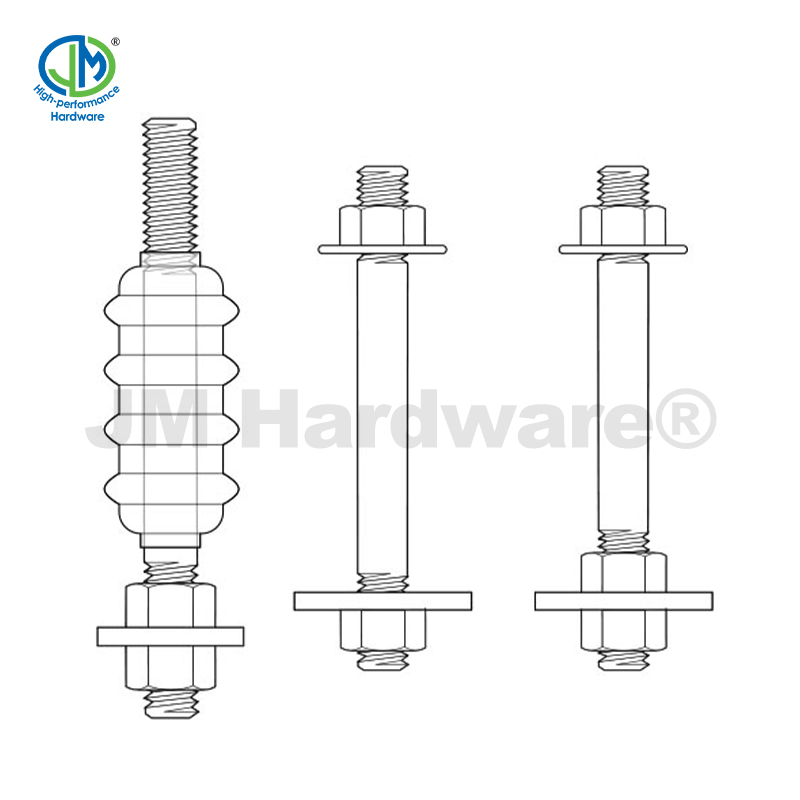

1.Anchor Bolts: Essential for securing poles and towers to their foundations. Available in J-Type, L-Type, Straight Type, and custom designs to meet your specific requirements.

2.U-Bolts: Used for securing cables, pipes, and braces to pole structures, ensuring firm and vibration-resistant connections.

3.Guy Clamps and Brackets: Critical for attaching guy wires to poles and towers, maintaining stability against wind and load forces.

4.Hex Bolts and Nuts: High-strength bolts and nuts designed for assembling tower components and pole fittings.

5.Threaded Rods: Used in tensioning and bracing applications to ensure structural integrity.

6.Flat and Lock Washers: Distribute loads and prevent fasteners from loosening due to vibration.

7.Eye Bolts and Eye Nuts: Serve as attachment points for cables and guy wires in transmission towers and poles.

8.Clevis and Yoke Plates: Heavy-duty connection components for insulator strings and tower fittings.

9.Line Spacers and Conductor Clamps: Secure and organize conductors for efficient transmission and reduced sagging.

10.Base Plates and Braces: Ensure stability and even load distribution in tower bases.

11.Hangers and Suspension Clamps: Used for securing power lines, fiber optics, or other cables to pole structures.

These hardware solutions are customizable to meet the specific demands of your tower or pole line project.

Materials for Tower and Pole Line Fasteners

Fasteners and hardware for tower and pole line projects are often exposed to extreme environmental conditions, including wind, rain, salt, and UV radiation. To ensure durability and long-lasting performance, we manufacture our products using the following materials:

1.Carbon Steel: Cost-effective and strong, ideal for general-purpose applications.

2.Hot-Dip Galvanized Steel: Provides exceptional corrosion resistance for outdoor and high-moisture environments.

3.Stainless Steel (SS304, SS316): Excellent for applications requiring high corrosion resistance, especially in coastal and marine areas.

4.Duplex Stainless Steel: Combines superior strength with resistance to chloride-induced corrosion, suitable for harsh conditions.

5.Alloy Steel: Ensures high tensile strength for load-bearing fasteners.

6.Aluminum: Lightweight and corrosion-resistant, commonly used for components in lightweight pole structures.

Copper and Copper Alloys: Ideal for electrical conductivity and corrosion resistance in grounding and electrical connections.

Surface Treatments for Enhanced Durability

Fasteners and hardware for tower and pole line projects must resist corrosion, wear, and extreme weather conditions. We offer a range of surface treatments to enhance performance:

Hot-Dip Galvanizing: A thick zinc coating provides long-term rust protection in outdoor environments.

Electroplating: Suitable for applications requiring a thinner, even coating.

Teflon Coating: Adds chemical resistance and reduces friction during installation.

Epoxy Coatings: Increases durability and is particularly effective in highly corrosive environments.

Anodizing (for Aluminum Parts): Provides additional corrosion resistance and improves surface hardness.

Black Oxide Coating: Adds a sleek finish while offering moderate corrosion resistance.

Key Applications in Tower and Pole Line Projects

Our fasteners and hardware are integral to the construction, maintenance, and operation of the following tower and pole line systems:

1.Transmission Towers: High-tensile bolts, nuts, and washers secure the steel lattice structures that support power lines across long distances.

2.Utility Poles: Anchor bolts and U-bolts ensure stability for wooden, concrete, or steel poles used in electrical distribution and telecommunication networks.

3.Communication Towers: Structural bolts, threaded rods, and bracing components connect modular tower segments for antennas and telecom equipment.

4.Lighting Poles: Fasteners secure base plates and components for streetlights, stadium lighting, and high-mast lighting systems.

5.Renewable Energy Towers: Specialized fasteners for wind turbine towers and solar panel mounting on pole systems.

6.Grounding Systems: Copper-based fasteners for electrical grounding to ensure safety and conductivity.

Testing and Quality Assurance

To meet the high demands of tower and pole line projects, we implement stringent quality control and testing procedures, ensuring every product meets or exceeds industry standards. Our testing methods include:

1.Tensile Strength Testing: Verifies the fastener’s ability to withstand heavy loads.

2.Salt Spray Testing: Ensures corrosion resistance for outdoor applications exposed to moisture and salt.

3.Fatigue Testing: Assesses performance under repeated load cycles, critical for towers in high-wind or vibration-prone areas.

4.Dimensional Inspection: Guarantees accurate sizing, threading, and fit.

5.Impact Testing: Validates the fastener’s ability to handle sudden shocks and stress.

6.Load Capacity Testing: Evaluates the performance of bolts, rods, and U-bolts under real-world conditions.

Production Process for Tower and Pole Line Hardware

As a trusted manufacturer, we follow a rigorous production process to ensure the highest quality:

1.Tensile Strength Testing: Verifies the fastener’s ability to withstand heavy loads.

2.Salt Spray Testing: Ensures corrosion resistance for outdoor applications exposed to moisture and salt.

3.Fatigue Testing: Assesses performance under repeated load cycles, critical for towers in high-wind or vibration-prone areas.

4.Dimensional Inspection: Guarantees accurate sizing, threading, and fit.

5.Impact Testing: Validates the fastener’s ability to handle sudden shocks and stress.

6.Load Capacity Testing: Evaluates the performance of bolts, rods, and U-bolts under real-world conditions.

Why Choose JM Hardware® for Tower and Pole Line Fasteners?

Extensive Product Range: From anchor bolts to conductor clamps, we offer a comprehensive selection.

High-Quality Materials: Durable materials and coatings for even the harshest environments.

Custom Manufacturing: Tailored solutions to meet the unique demands of your project.

Global Supply Chain: Reliable and timely delivery to project sites worldwide.

Strict Quality Standards: Every product undergoes rigorous testing to ensure reliability and performance.

Experienced Team: Decades of expertise in supplying fasteners for tower and pole line applications.

Contact JM Hardware® for Tower and Pole Line Solutions

Whether you're building transmission towers, utility poles, or communication systems, JM Hardware® has the expertise and products you need. Contact us today to learn more about our fasteners and hardware for tower and pole line projects or to discuss your custom requirements. Trust us to deliver reliable solutions that meet your project's needs!

Get in Touch with JM Hardware®

Xarella Huang

-

Whatsapp

+86 13681923533

-

Wechat/Tel

+86 18621005605

-

E-mail