-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

Fasteners for Highway Contractors

At JM Hardware®, we understand the critical role fasteners play in the success of highway construction projects. From securing guardrails and signposts to anchoring large structural elements, highway contractors rely on high-performance fasteners that deliver durability, reliability, and compliance with strict safety standards. Our wide range of products and tailored solutions ensures that we meet the diverse needs of highway contractors while maintaining the highest level of quality and precision.

Comprehensive Fastener Solutions for Highway Contractors

We supply a wide variety of fasteners that cater to the specific requirements of highway projects, including:

Guardrail Bolts and Nuts: Designed to securely fasten highway guardrails, our bolts and nuts provide the strength and corrosion resistance necessary to withstand constant exposure to weather and impact.

Anchor Bolts: Heavy-duty bolts for securing road signage, light poles, and overhead structures to concrete foundations.

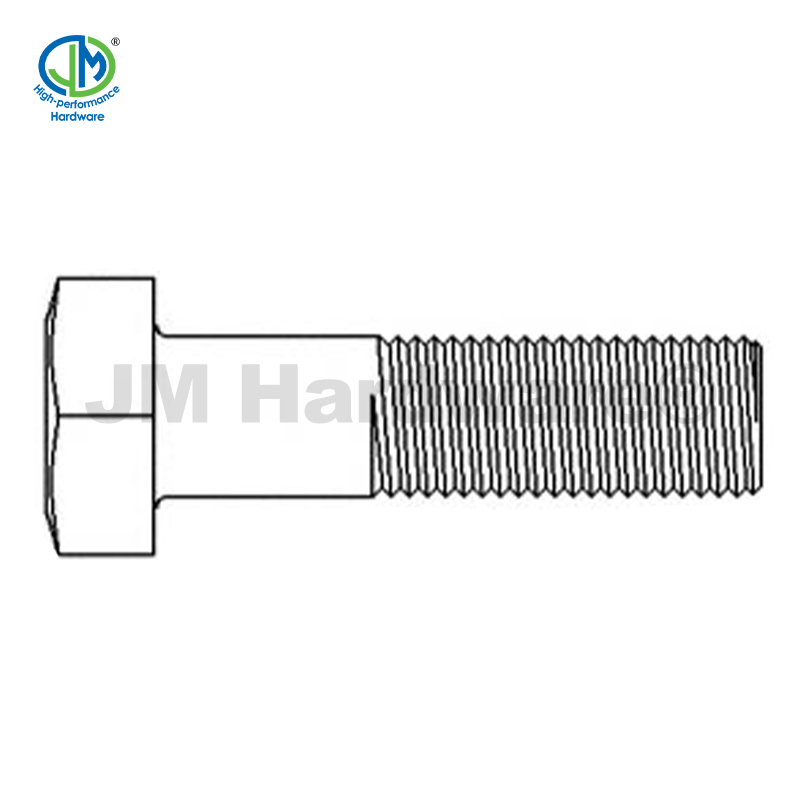

Hex Bolts and Structural Bolts: Ideal for bridges, retaining walls, and other highway structures requiring high-strength connections.

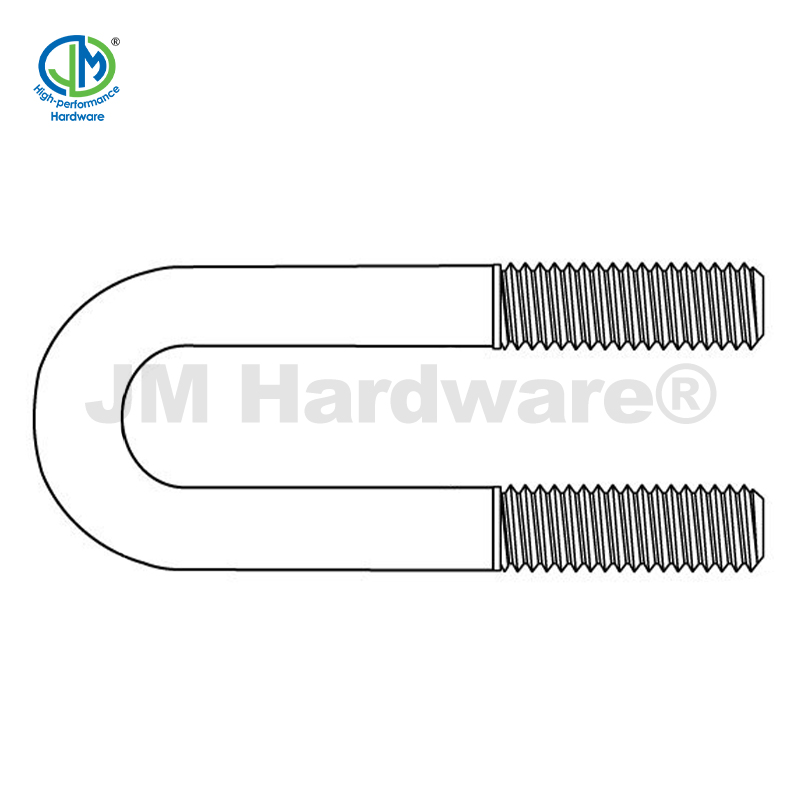

U-Bolts: Used for fastening pipes and components in highway drainage systems.

Expansion Bolts: Suitable for connecting concrete barriers or attaching components to pre-existing infrastructure.

Washers: Load-distributing flat and lock washers for added stability and vibration resistance in high-traffic environments.

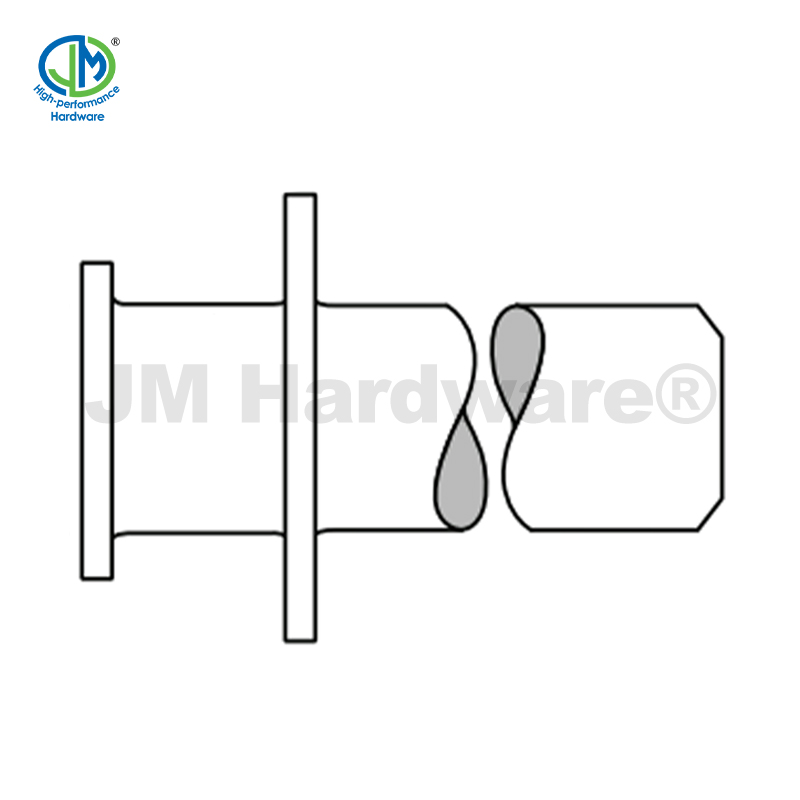

Shear Bolts: Anti-theft solutions for roadside equipment, such as signs and solar-powered lighting.

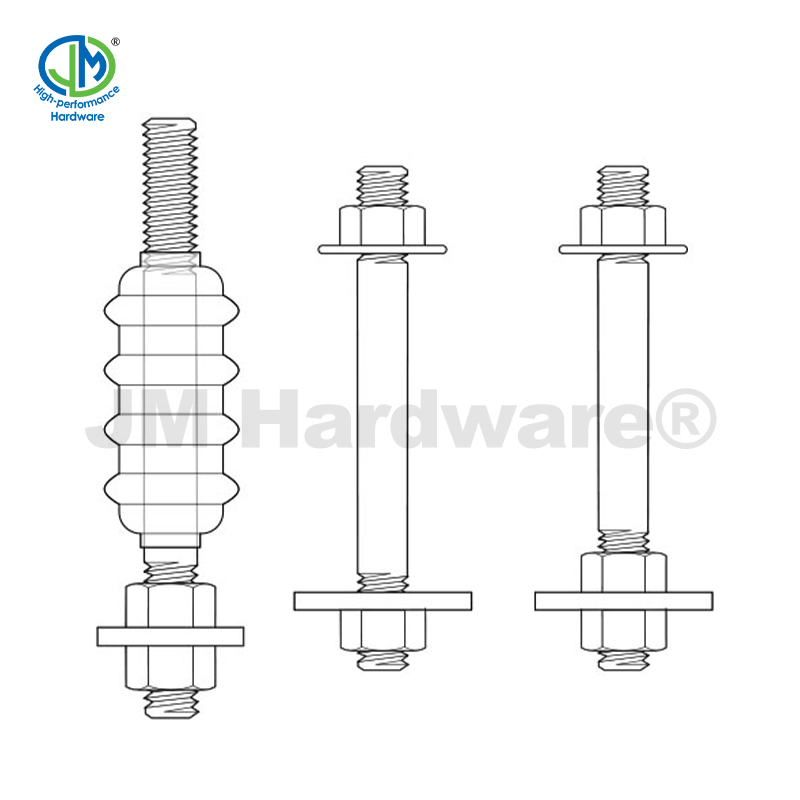

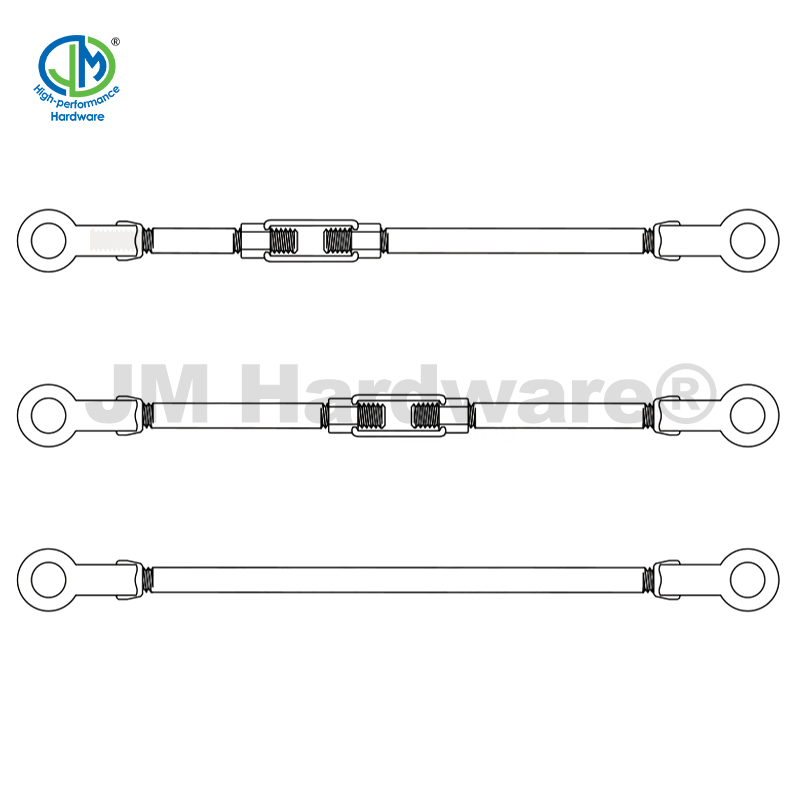

Threaded Rods: For custom installations and applications requiring adjustable length fasteners.

We also offer custom fasteners for unique project requirements, ensuring the right solution for even the most complex highway applications.

Materials for Highway Fasteners

Highway infrastructure faces constant exposure to harsh environments, including heavy rain, snow, salt, and vibrations. To meet these challenges, JM Hardware® manufactures fasteners using the following materials:

1.Carbon Steel: Offers excellent strength and affordability for general-purpose applications.

2.Stainless Steel (SS304, SS316): Provides outstanding corrosion resistance, making it ideal for guardrails, signage, and bridge components.

3.Galvanized Steel: Hot-dip galvanized bolts and nuts are perfect for outdoor environments due to their superior rust protection.

4.Alloy Steel: Suitable for high-strength applications, such as securing bridge structures or heavy highway equipment.

5.Duplex Stainless Steel: Combines exceptional strength with excellent resistance to saltwater corrosion, perfect for coastal highway projects.

6.Brass and Aluminum: Used in lightweight applications, such as electrical junction boxes for highway lighting systems.

Surface Finishes for Enhanced Durability

Fasteners for highway projects are treated with a variety of coatings to improve performance and extend lifespan:

Hot-Dip Galvanizing: Provides strong corrosion resistance, particularly for outdoor and marine environments.

Teflon Coating: Adds a layer of chemical resistance and reduces friction during installation.

Black Oxide Coating: Enhances aesthetics while providing moderate rust protection.

Zinc Plating: Offers a cost-effective solution for rust resistance.

Epoxy Coatings: High-durability coatings suitable for harsh weather conditions.

Powder Coating: Adds extra protection for fasteners used in roadside signage or decorative elements.

Applications in Highway Projects

Our fasteners are used in a wide range of highway construction and maintenance applications, including:

1.Guardrails and Crash Barriers: High-tensile bolts and nuts secure the panels, posts, and end treatments of highway guardrails, ensuring structural integrity and safety.

2.Signage Installation: Anchor bolts and structural fasteners attach traffic signs, overhead gantries, and road markers to foundations.

3.Bridge Construction: Heavy-duty bolts and threaded rods are used to assemble bridge components, from girders to expansion joints.

4.Lighting and Poles: Anchor bolts and washers secure streetlights, traffic signals, and camera poles.

5.Noise Barriers: Fasteners connect pre-fabricated panels to steel or concrete supports along highways.

6.Drainage Systems: U-bolts and threaded rods secure pipes and drainage infrastructure to minimize flooding risks.

7.Solar Installations: Corrosion-resistant bolts for attaching solar panels to roadside equipment or foundations.

8.Fencing and Barriers: Fasteners secure fencing and anti-climbing barriers along highways and bridges.

Quality Assurance and Testing

To ensure the safety and longevity of highway infrastructure, all our fasteners undergo rigorous quality control processes. Our testing methods include:

1.Tensile Strength Testing: Guarantees that fasteners can withstand the high loads and stresses experienced in highway applications.

2.Salt Spray Testing: Verifies corrosion resistance, especially for fasteners exposed to de-icing salts, rain, and snow.

3.Vibration Testing: Ensures stability in high-traffic environments, where constant vibrations can loosen fasteners.

4.Dimensional Accuracy Testing: Ensures precision in size, threads, and alignment for seamless installation.

5.Fatigue Testing: Confirms fasteners can handle repeated loads and cycles over extended periods.

6.Impact Resistance Testing: Validates performance in crash or heavy-impact scenarios, such as guardrail collisions.

Customized Fastener Solutions for Highway Contractors

At JM Hardware®, we recognize that each highway project has unique requirements. That’s why we offer custom fastener solutions tailored to your specific needs, including:

Non-Standard Sizes: We manufacture fasteners to your exact dimensions.

Special Materials: Selection of materials to meet environmental or project-specific demands.

Custom Kits: Pre-packaged fastener kits for quick and efficient on-site assembly.

Project-Specific Coatings: Coatings like epoxy or Teflon for specialized applications.

Why Choose JM Hardware® for Highway Fasteners?

1.Wide Product Range: Comprehensive selection of fasteners for all highway applications.

2.Durability and Performance: Materials and coatings designed for long-term use in harsh environments.

3.Custom Manufacturing: Tailored solutions to meet unique project requirements.

4.Global Delivery: Reliable and on-time shipping to project sites worldwide.

5.Strict Quality Control: Rigorous testing to ensure compliance with industry standards.

6.Experienced Team: Decades of expertise in supplying fasteners for highway and infrastructure projects.

Contact JM Hardware® for Highway Fastener Solutions

Whether you’re securing guardrails, installing signage, or building bridges, JM Hardware® has the expertise and fasteners you need for a successful highway project. Contact us today to discuss your requirements or request a custom solution. Trust JM Hardware® as your reliable partner in providing high-quality fasteners for highway contractors!