-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

Fasteners for Marine Construction

At JM Hardware®, we provide high-quality fasteners for marine construction, designed to withstand the harshest marine environments. Marine construction projects—such as piers, docks, seawalls, and offshore structures—demand fasteners that are not only durable but also resistant to corrosion, high salt concentrations, and extreme weather conditions. Our comprehensive range of marine fasteners ensures the safety, longevity, and reliability of every project, no matter how demanding.

Comprehensive Fastener Solutions for Marine Construction

In marine construction, fasteners are essential to securely connect components while enduring constant exposure to water, salt, and high winds. We offer a variety of fastener products, including:

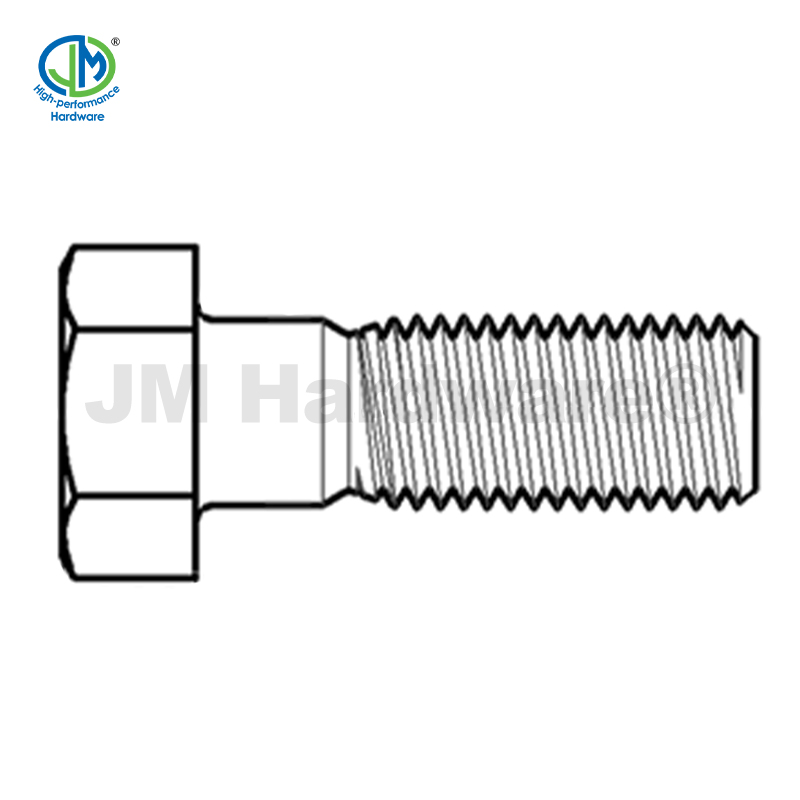

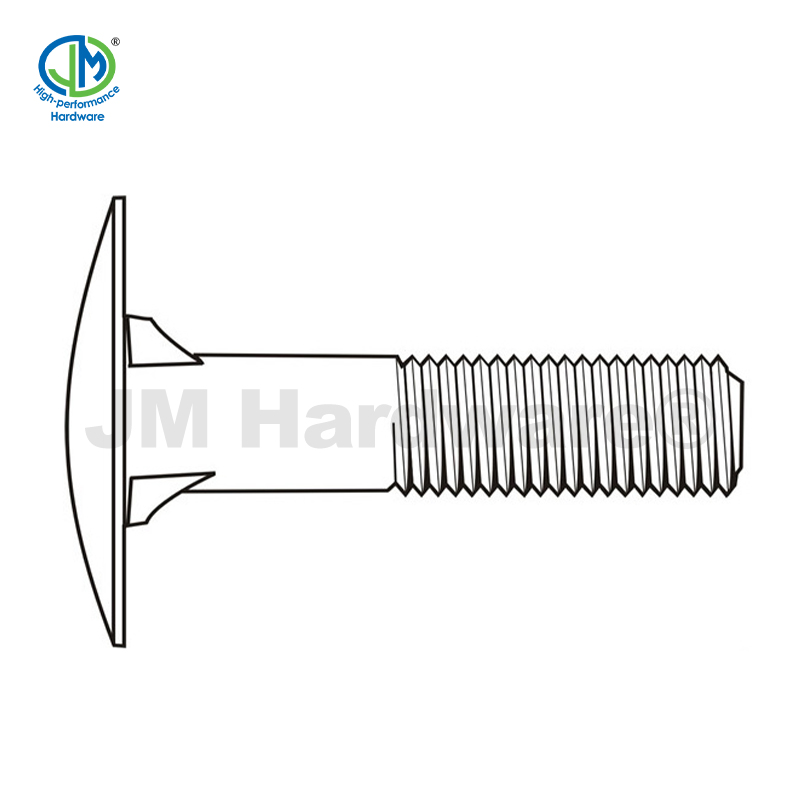

Marine-Grade Bolts: Heavy-duty bolts for securing large steel or concrete components, such as foundations, bridges, and offshore platforms.

Stainless Steel Nuts: Corrosion-resistant nuts designed to provide a reliable and long-lasting connection for marine structures.

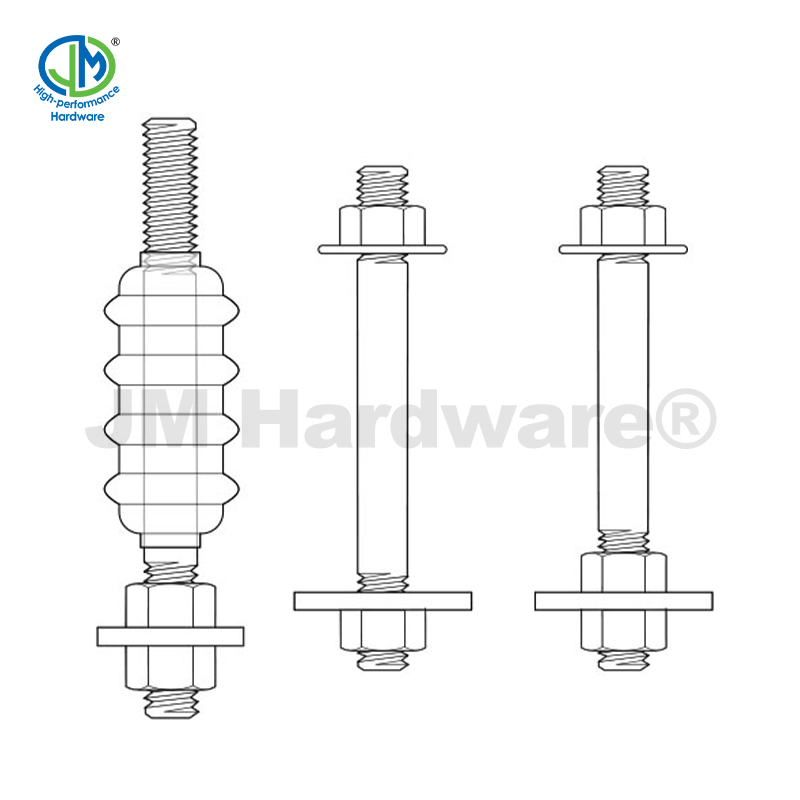

Threaded Rods: Used in marine applications to join various structural components, providing high tensile strength.

Anchoring Bolts: Specially designed for deep-water applications, these bolts ensure the security of large marine structures.

Eye Bolts: Ideal for lifting and securing large marine components during installation or maintenance.

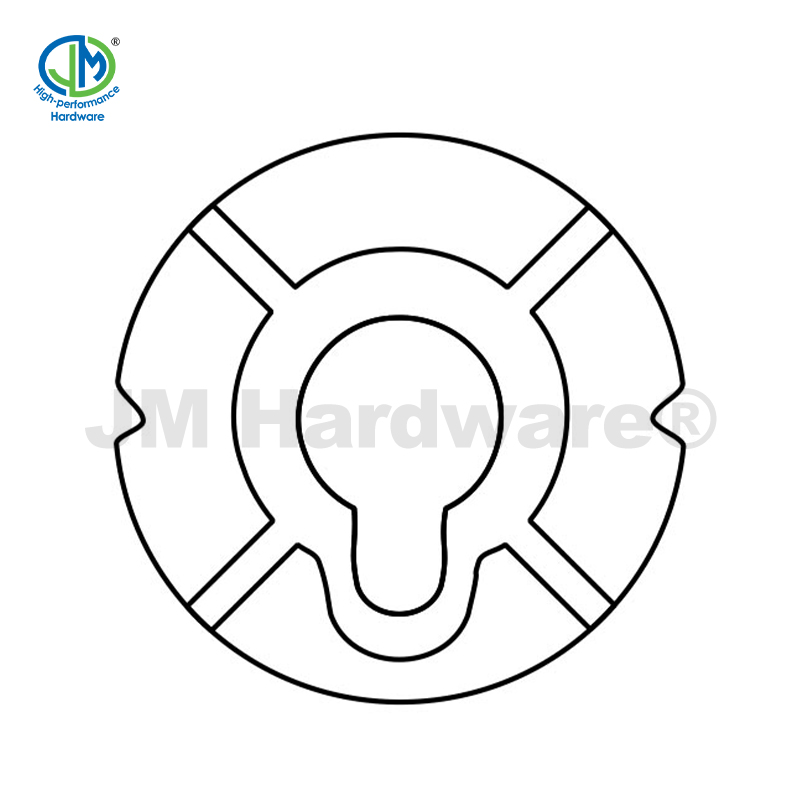

Washers and Lock Washers: Ensure proper load distribution and prevent loosening under dynamic loads, vital in high-vibration environments like offshore rigs.

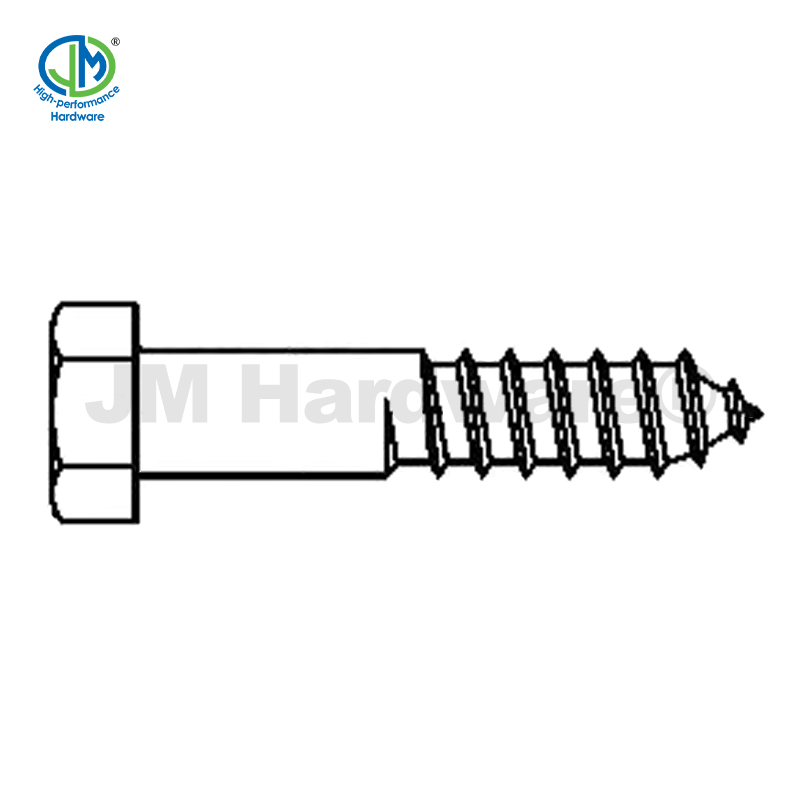

Self-Tapping Screws: Used in sheet metal installations, ideal for securing panels and other components in marine environments.

Marine Rivets: Used for joining thin materials, such as sheets or panels, in shipbuilding and boat manufacturing.

We can also manufacture custom marine fasteners to meet specific project requirements and adapt to unusual or highly challenging environmental conditions.

Materials for Marine Construction Fasteners

Marine construction environments are highly corrosive, requiring fasteners made from materials that can resist saltwater, moisture, and fluctuating temperatures. At JM Hardware®, we offer marine fasteners made from the following materials:

1.Stainless Steel (SS304, SS316): Stainless steel is the go-to material for marine environments due to its superior resistance to corrosion, rust, and pitting. SS316 is particularly ideal for seawater applications, providing excellent protection against chloride-induced corrosion.

2.Duplex Stainless Steel: A highly corrosion-resistant material combining the benefits of austenitic and ferritic steels, making it perfect for coastal and offshore projects.

3.Titanium: Known for its exceptional strength and corrosion resistance, especially in harsh marine environments such as deep-sea applications.

4.Monel Alloy: Resistant to seawater corrosion, Monel is ideal for high-performance fasteners in marine structures and vessels.

5.Aluminum: Lightweight and corrosion-resistant, often used in smaller marine construction projects such as docks and boats.

6.Brass: Excellent for saltwater applications, offering moderate strength and high resistance to corrosion.

7.Copper-Nickel Alloys: Known for their outstanding resistance to marine corrosion, these alloys are commonly used in marine piping systems and offshore rigs.

Surface Treatments for Enhanced Durability

In marine construction, fasteners must endure constant exposure to water, salt, and extreme weather. To maximize the lifespan and performance of our fasteners, we offer the following surface finishes:

Hot-Dip Galvanizing: Provides excellent corrosion protection, especially for fasteners exposed to seawater or salt air.

Electroplating (Zinc, Nickel): Offers a cost-effective solution for corrosion resistance, ensuring fasteners remain strong and durable in marine applications.

Anodizing: Used for aluminum fasteners to improve corrosion resistance and provide an aesthetic finish, often used in lightweight marine structures.

Teflon Coating: Adds an additional layer of corrosion resistance, ideal for fasteners exposed to aggressive marine environments.

Passivation: A treatment that enhances the natural corrosion resistance of stainless steel fasteners, ensuring long-term durability.

Dacromet Coating: An advanced corrosion-resistant coating used in applications exposed to aggressive marine environments.

Key Applications of Marine Construction Fasteners

Our marine fasteners are used in a variety of critical applications, including:

1.Offshore Oil Rigs: Fasteners are used in the construction and maintenance of offshore drilling platforms, where high-strength and corrosion-resistant fasteners are essential.

2.Harbors and Piers: Heavy-duty bolts, anchor bolts, and stainless steel nuts are used to secure the foundation structures of piers, docks, and waterfront infrastructure.

3.Shipbuilding: From hull construction to interior fittings, marine-grade rivets, bolts, and fasteners are used to secure components in shipbuilding projects.

4.Bridges and Waterfront Structures: Fasteners for securing large concrete or steel components of bridges and other large structures near or on the water.

5.Seawalls and Retaining Walls: Fasteners are used to connect and secure the various components of coastal protection systems.

6.Floating Structures: In projects involving floating bridges, pontoons, or floating docks, fasteners must withstand constant exposure to water and salt.

7.Marine Furniture: Corrosion-resistant fasteners are used in constructing boats, yachts, and offshore platforms where longevity and strength are key.

Quality Assurance and Testing for Marine Fasteners

The quality and performance of our marine fasteners are paramount, especially in critical applications like offshore drilling and shipbuilding. To ensure that every fastener meets the highest standards, we conduct the following testing procedures:

1.Corrosion Resistance Testing: Ensures fasteners can endure prolonged exposure to seawater and salty environments.

2.Tensile Strength Testing: Guarantees that fasteners can withstand high loads without failure.

3.Dimensional Inspection: Verifies that fasteners meet the required specifications for size, threads, and performance.

4.Impact Testing: Ensures fasteners remain stable even under high-impact conditions, such as during shipping or heavy use.

5.Vibration Testing: Simulates marine conditions to test the fastener’s ability to remain secure under constant movement and vibrations.

6.Salt Spray Testing: Specifically designed for marine applications, this test evaluates the corrosion resistance of fasteners in salt-laden environments.

Customized Fastener Solutions for Marine Construction

We understand that every marine construction project is unique, which is why JM Hardware® offers custom fastener solutions. Whether you need specific materials, non-standard sizes, or custom coatings, we can deliver tailored products that meet your project requirements. Additionally, we offer:

Custom Kitting: Pre-packaged fasteners for easy installation on-site.

Non-Standard Sizes: Fasteners manufactured to meet your specific dimensions and design.

Project-Specific Coatings: Coatings like Teflon, galvanizing, or anodizing to meet the environmental conditions of your project.

Why Choose JM Hardware® for Marine Construction Fasteners?

1.Durability and Corrosion Resistance: Our fasteners are specifically designed to withstand the harshest marine conditions.

2.Comprehensive Product Range: From bolts and nuts to rivets and washers, we provide everything needed for marine construction.

3.Global Reach: We serve marine construction projects worldwide, ensuring timely delivery and consistent quality.

4.Custom Manufacturing: We offer custom fasteners to meet the unique requirements of your marine projects.

5.High-Quality Materials: Only premium-grade materials are used, ensuring optimal strength and longevity in marine applications.

6.Extensive Testing: Our fasteners undergo rigorous testing to meet industry standards and ensure top-tier performance.

Contact JM Hardware® for Marine Construction Fasteners

Whether you're constructing a bridge, securing offshore structures, or building ships, JM Hardware® has the fasteners you need to ensure the safety and longevity of your marine projects. Contact us today for more information or to request a custom solution tailored to your marine construction requirements!