-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

Fasteners for the Petrochemical Industry

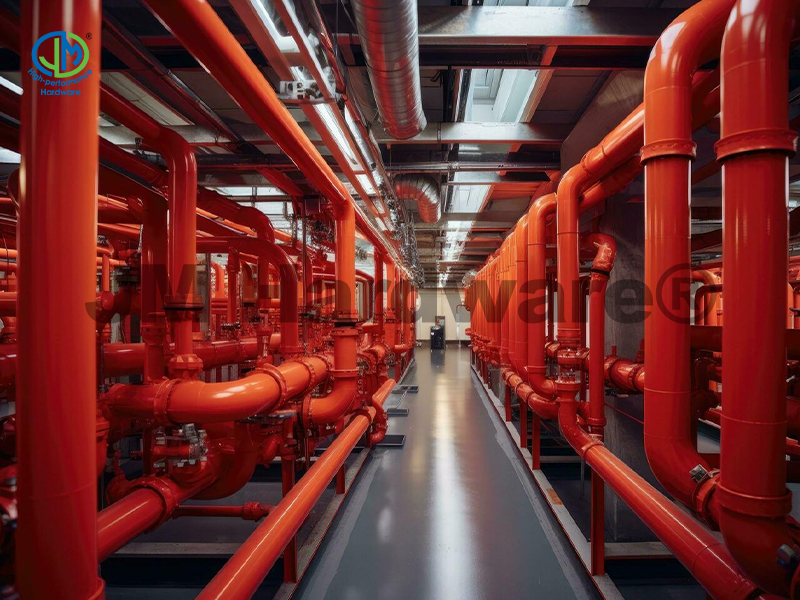

At JM Hardware®, we specialize in providing high-performance fasteners tailored to the demanding needs of the petrochemical industry. Petrochemical plants and facilities require fasteners that can withstand extreme temperatures, pressure, and corrosive environments while ensuring the integrity and safety of critical systems. Our fasteners are engineered for durability, reliability, and efficiency in applications ranging from pipelines and reactors to storage tanks and refineries.

Comprehensive Fastener Solutions for the Petrochemical Industry

We offer a wide range of fasteners designed to meet the specific challenges faced in the petrochemical sector. Our product lineup includes:

Flange Bolts: Used for securing flanged connections in pipelines, valves, and other equipment that require tight, leak-proof seals.

Anchor Bolts: Heavy-duty bolts used for securing structural components, equipment, and machinery to concrete foundations in petrochemical plants.

Hex Head Bolts: Widely used for general fastening applications, such as securing pipes, tanks, and reactors.

Stud Bolts: Essential for high-pressure applications where full thread engagement and stability are crucial.

Washers: Load-distributing washers designed to improve the performance of bolted joints in high-stress and high-temperature environments.

U-Bolts: Ideal for securing pipes, rods, or other components in piping systems.

Eye Bolts: Used for lifting and securing heavy equipment or reactor components.

Self-Locking Nuts: Designed for use in high-vibration environments to prevent loosening over time.

Rivets and Threaded Inserts: For permanent, vibration-resistant joints in tanks, reactors, and pipes.

Additionally, we provide custom fastener solutions to meet unique petrochemical project requirements, including specialty materials, custom dimensions, and surface coatings.

Materials for Petrochemical Fasteners

The harsh conditions in the petrochemical industry require fasteners made from high-strength, corrosion-resistant materials. At JM Hardware®, we manufacture fasteners using the following materials:

1.Stainless Steel (SS304, SS316): Excellent corrosion resistance, ideal for applications exposed to chemicals, acids, and high humidity.

2.Alloy Steel: High strength, used in applications requiring load-bearing fasteners that can resist high temperatures and pressures.

3.Inconel & Monel Alloys: Specialized alloys designed for extreme heat and aggressive corrosive environments, particularly in high-temperature reactors and gas processing.

4.Duplex Stainless Steel: Offers a combination of high strength and superior resistance to chloride stress corrosion cracking, making it perfect for coastal and offshore applications.

5.Titanium: Extremely corrosion-resistant, ideal for highly corrosive environments like acid plants and offshore platforms.

6.Carbon Steel (Galvanized and Black Oxide Coatings): Provides an affordable yet robust solution for structural applications that require moderate corrosion resistance.

7.Nickel Alloys: Suitable for high-stress and high-temperature applications, especially in reactors, pressure vessels, and pipelines.

Surface Coatings for Petrochemical Fasteners

Fasteners in the petrochemical industry are exposed to aggressive chemicals, high temperatures, and extreme pressure. To improve their performance and longevity, we offer a range of surface treatments:

Hot-Dip Galvanizing: Provides corrosion resistance in outdoor and humid environments, particularly for structural and piping systems.

Electroplating (Zinc, Nickel, Chrome): Offers moderate corrosion resistance and is commonly used for smaller fasteners or components in non-aggressive environments.

Teflon Coating: Provides a non-stick surface and chemical resistance, making it ideal for fasteners used in highly corrosive conditions.

Black Oxide Coating: Provides a sleek finish with moderate rust resistance, typically used for fasteners in low-humidity and indoor environments.

Dacromet Coating: A high-performance coating for corrosion resistance, often used in extreme petrochemical environments.

Passivation: An essential process for stainless steel fasteners to remove surface contaminants and enhance corrosion resistance, especially in high-salinity environments.

PTFE Coating: Ideal for chemical resistance, reducing friction and wear while extending the fasteners' life.

Applications in the Petrochemical Industry

Fasteners in the petrochemical industry are critical in ensuring the safety and integrity of complex systems that handle corrosive substances, high-pressure environments, and extreme temperatures. Our fasteners are used in a variety of applications, including:

1.Pipelines and Piping Systems: Bolts, studs, and nuts for securing piping and preventing leaks in both high and low-pressure systems.

2.Pressure Vessels: High-strength fasteners are used to secure pressure vessel components, which are subject to extreme pressure and temperature variations.

3.Reactors and Heat Exchangers: Stud bolts and flange bolts for securing reactors, heat exchangers, and other critical systems in processing plants.

4.Storage Tanks: Heavy-duty fasteners for securing large tanks, vessels, and reservoirs that store chemicals, gases, and petrochemical products.

5.Refineries: Fasteners for securing components in oil refineries, such as distillation columns, separators, and catalytic crackers.

6.Offshore Platforms: Corrosion-resistant fasteners for securing structural components and machinery in offshore oil rigs and platforms.

7.Chemical Processing Units: Fasteners used in equipment such as mixers, reactors, and distillers, where corrosion resistance and high strength are critical.

8.Compressor Units: Specially designed fasteners for securing compressors and pumps that operate under high pressures and frequent vibration.

Quality Assurance and Testing

At JM Hardware®, we maintain strict quality control standards to ensure that our fasteners perform reliably in the harsh petrochemical environment. Our quality assurance processes include:

1.Tensile Strength Testing: Ensures that fasteners can withstand the high stresses and loads typical in petrochemical applications.

2.Salt Spray Testing: Evaluates the corrosion resistance of fasteners exposed to salty or humid environments, ensuring longevity in offshore and coastal facilities.

3.Dimensional Accuracy Testing: Confirms that all fasteners meet the required specifications for safe and reliable installation.

4.Impact and Vibration Testing: Ensures fasteners can perform under dynamic loads and vibrations, which are common in petrochemical operations.

5.Hardness Testing: Verifies the material hardness of fasteners to ensure they can handle high-pressure and high-temperature environments without deformation.

Why Choose JM Hardware® for Petrochemical Fasteners?

1.Wide Product Range: From nuts and bolts to specialized fasteners, we have the right solution for every petrochemical application.

2.Durability and Corrosion Resistance: We provide fasteners made from high-quality materials and advanced coatings to ensure long-term performance in aggressive environments.

3.Custom Manufacturing: We offer custom fastener solutions tailored to meet your specific petrochemical project needs.

4.Global Reach: Our fasteners are supplied to petrochemical projects worldwide, ensuring reliable service and on-time delivery.

5.Industry Expertise: With years of experience in supplying fasteners for the petrochemical industry, we understand the specific challenges and requirements of this sector.

6.Rigorous Quality Control: We test all fasteners to ensure they meet the highest industry standards for safety, performance, and reliability.

Contact JM Hardware® for Petrochemical Fastener Solutions

Whether you’re working on an offshore oil rig, a chemical processing plant, or a refinery, JM Hardware® provides the highest quality fasteners designed to withstand the toughest petrochemical applications. Contact us today to discuss your requirements or request a custom fastener solution for your project. Let us be your trusted partner for fastener solutions in the petrochemical industry!