-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a trusted Super Duplex Stainless Steel Manufacturer, offering high-performance fasteners and components tailored to meet the demanding needs of various industries. Super Duplex Stainless Steel stands out for its exceptional strength, superior corrosion resistance, and cost-effectiveness in critical applications. As experts in manufacturing and delivering top-quality Super Duplex SS products, we ensure our clients receive precision-engineered components designed to excel in harsh environments.

What Is Super Duplex Stainless Steel? Why Choose It?

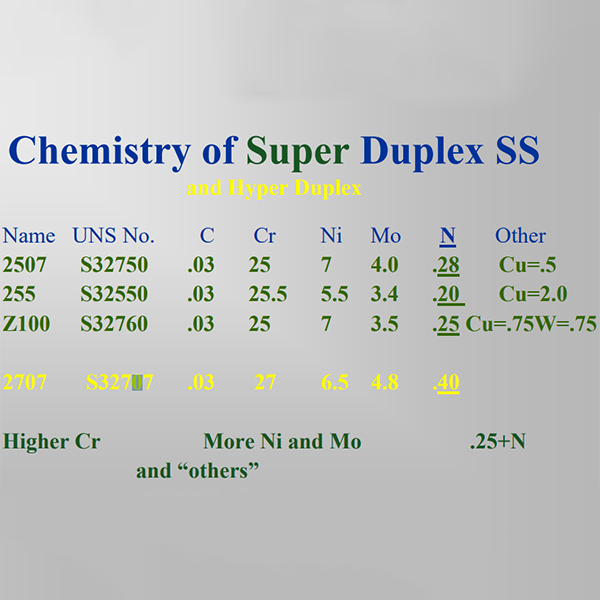

Super Duplex Stainless Steel (SDSS) is an advanced alloy that combines the best properties of austenitic and ferritic stainless steels. Its unique composition (containing higher levels of chromium, molybdenum, and nitrogen) results in:

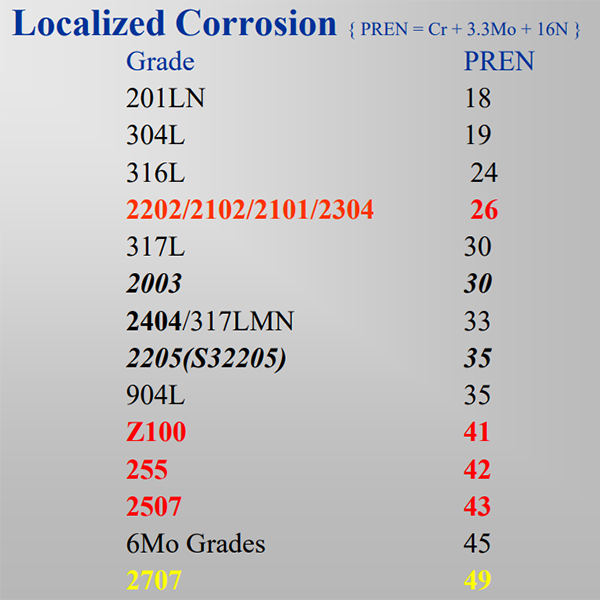

- Superior Corrosion Resistance: With excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, Super Duplex SS outperforms standard stainless steels in harsh environments, such as saltwater, chemicals, and acidic atmospheres.

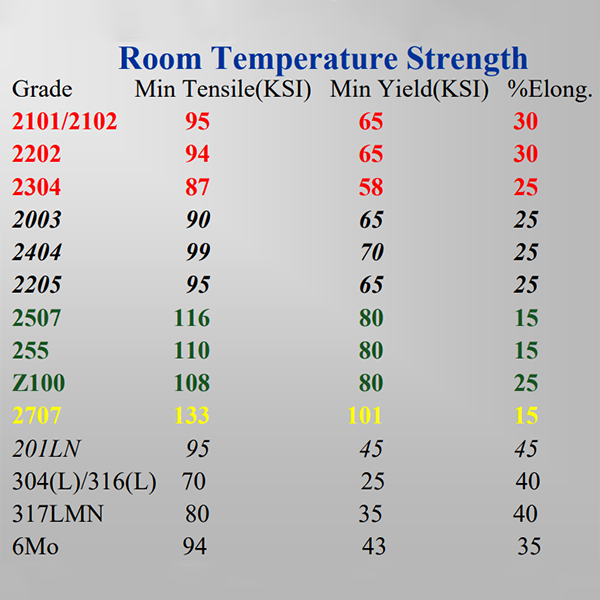

- Exceptional Strength: Super Duplex SS offers twice the yield strength of regular austenitic stainless steel, such as SS304 and SS316, making it ideal for high-pressure and heavy-load applications.

- Enhanced Durability: High resistance to mechanical wear and deformation ensures long-lasting performance, even in extreme conditions.

- Cost-Effectiveness: Its increased strength and corrosion resistance enable reduced material usage, minimizing costs in demanding projects.

Typically grade EN 1.4410 up to so-called hyper duplex grades (PREN: >45) developed later to meet specific demands of the oil and gas as well as those of the chemical industries. They offer a superior corrosion resistance and strength but are more difficult to process because the higher contents of Cr, Mo, N and even W promote the formation of intermetallic phases, which reduce drastically the impact resistance of the steel. Faulty processing will result in poor performance and users are advised to deal with reputable suppliers/processors.Applications include deepwater offshore oil production.

Specification

| Lean Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| 2101 | S32101 | 1.4162 | 0,04 | 21,0-22,0 | 1,35-1,7 | 0,1 – 0,8 | 0,20-0,25 | 4,0-6,0 | 0,1-0,8 | – | 26 | |

| F66 | 2202 | S32202 | 1.4062 | 0,03 | 21,5-24,0 | 1,0-2,8 | 0,45 | 0,18-0,26 | 2,0 | – | 26 | |

| F68 | 2304 | S32304 | 1.4362 | 0,03 | 21,5-24,5 | 3,0-5,5 | 0,05-0,6 | 0,05-0,20 | 2,5 | 0,05-0,60 | – | 26 |

| 2102 | S82011 | 0,03 | 20.5-23.5 | 1.00-2.00 | 0,1 – 1.00 | 0.15-0.27 | 2.00-3.00 | 0.5 | – | 26 | ||

| Standard Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| F51 | 2205 | S31803 | 1.4462 | 0,03 | 21,0-23,0 | 4,5-6,5 | 2,5-3,5 | 0,08-0,20 | 2,0 | – | – | 33 |

| F60 | 2205 | S32205 | 1.4462 | 0,03 | 22,0-23,0 | 4,5-6,5 | 3,0-3,5 | 0,14-0,20 | 2,0 | – | – | 35 |

| 2003 | S32003 | 1.4662 | 0,03 | 19.5-22.5 | 3.0-4.0 | 1.5-2.0 | 0.14-0.2 | 2,0 | – | – | 30 | |

| 2404 | S82441 | 1.4662 | 0,03 | 23.0-25.0 | 3.0-4.5 | 1.00-2.00 | 0.20-0.30 | 2.5-4.0 | 0.10-0.80 | – | 33 | |

| Super Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| F59 | S32520 | 1.4507 | 0,03 | 24,0-26,0 | 5,5-8,0 | 3,0-4,0 | 0,20-0,35 | 1,5 | 0,5-2,0 | – | >40 | |

| F61 | 255 | S32550 | 1.4507 | 0,04 | 24,0-27,0 | 4,5-6,5 | 2,9-3,9 | 0,10-0,25 | 1,5 | 1,5-2,5 | – | >40 |

| F53 | 2507 | S32750 | 1.441 | 0,03 | 24,0-26,0 | 6,0-8,0 | 3,0-5,0 | 0,24-0,32 | 1,2 | 0,50 | – | 43 |

| F55 | Z100 | S32760 | 1.4501 | 0,03 | 24,0-26,0 | 6,0-8,0 | 3,0-4,0 | 0,20-0,30 | 1,0 | 0,5-1,0 | 0,5-1,0 | 42 |

| Hyper Duplex | ||||||||||||

| Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* | |

| 2707 | S32707 | – | 0,03 | 26,0-29,0 | 5,5-9,5 | 4,0-5,0 | 0,30-0,50 | 1,5 | 1,00 | – | 49 | |

| 3207 | S33207 | – | 0,03 | 29,0-33,0 | 6,0-9,0 | 3,0-5,0 | 0,40-0,60 | 1,5 | 1,00 | – | 50 | |

| Austenitic Grades | ||||||||||||

| ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn | Cu | W | PRE* | ||

| 304L | 1.4307 | 0,03 | 17,5-19,5 | 8,0-10,5 | – | 0,11 | – | – | – | 18 | ||

| 316L | 1.4404 | 0,03 | 16,5-18,5 | 10,0-13,0 | 2,0-2,5 | 0,10 | – | – | – | 24 | ||

| 904L | 1.4539 | 0,02 | 19,0-21,0 | 24,0-26,0 | 4,0-5,0 | 0,15 | – | 1,20 | – | 34 | ||

| S31254 | 1.4547 | 0,2 | 19,5-20,5 | 17,5-18,5 | 6,0-7,0 | 0,18-0,25 | – | 0,5-1,0 | – | 43 | ||

Our Super Duplex Stainless Steel Products

As a Super Duplex Stainless Steel Manufacturer, we provide a comprehensive range of fasteners and components, including:

- Bolts and Nuts: Hex bolts, heavy hex nuts, stud bolts, U-bolts, and more, designed for maximum strength in high-pressure and corrosive environments.

- Threaded Rods: Manufactured with precision threading to ensure secure connections in construction and industrial applications.

- Washers: Flat washers, lock washers, and custom washers for load distribution and vibration resistance.

- Screws: High-performance screws, including self-tapping and machine screws, tailored for critical applications.

- Custom Components: We can manufacture non-standard components to your specific requirements, ensuring compatibility with your unique applications.

Unique Properties of Super Duplex Stainless Steel Components

What sets Super Duplex Stainless Steel products apart?

- High Strength-to-Weight Ratio: Super Duplex SS fasteners deliver outstanding mechanical performance without adding excessive weight, making them ideal for aerospace, marine, and offshore applications.

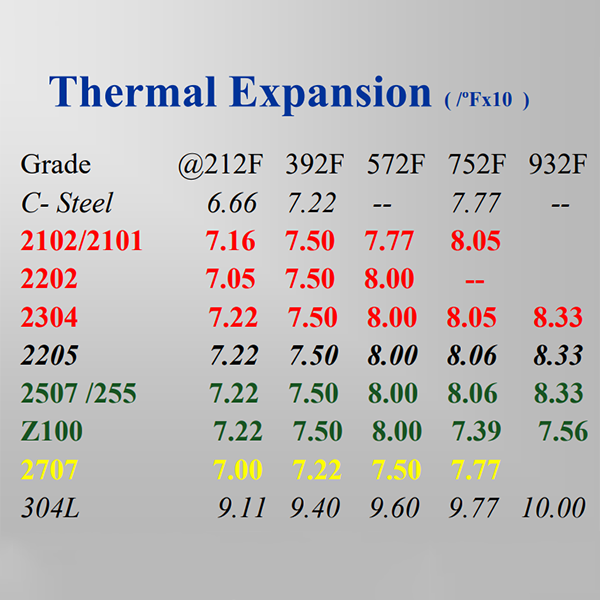

- Extreme Temperature Resistance: With excellent performance in temperatures ranging from -50°C to over 300°C, our fasteners are suitable for a wide range of environments.

- Low Maintenance Requirements: Thanks to its superior resistance to wear and corrosion, Super Duplex SS products require less frequent replacement and maintenance, reducing downtime and costs.

- Environmentally Friendly: Super Duplex SS is 100% recyclable, contributing to sustainable practices in industrial projects.

Forms of Super Duplex SS Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4"-4", M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4"-4", M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2"-4", M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2"-4", M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8"-4", M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8"-4", M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4"-4", M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2"-4", M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2"-4", M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2"-4", M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2"-4", M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2"-4", M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2"-4", M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2"-4", M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8"-4", M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8"-4", M6-M100 |

Testing and Quality Assurance

At JM Hardware®, quality is our priority. Every Super Duplex Stainless Steel product undergoes rigorous testing to meet the highest industry standards. Our testing methods include:

- Tensile Testing: Ensures the product meets the required strength.

- Hardness Testing: Verifies the material’s durability.

- Salt Spray Testing: Measures corrosion resistance in extreme environments.

- Dimensional Accuracy Testing: Confirms precise measurements for seamless integration.

- Impact Testing: Ensures reliability under sudden or heavy loads.

- Non-Destructive Testing (NDT): Ultrasonic and radiographic inspections to detect internal flaws.

Advanced Manufacturing Processes

As a professional Super Duplex Stainless Steel Manufacturer, we utilize cutting-edge manufacturing techniques to produce high-quality products:

- Precision Forging: Ensures accurate shaping and strength in every component.

- CNC Machining: Allows for high precision and repeatability in complex designs.

- Heat Treatment: Optimizes the mechanical properties and corrosion resistance of Super Duplex SS.

- Cold and Hot Working: Tailored processes to enhance material properties based on application needs.

- Thread Rolling: Creates strong, precise threads for reliable connections.

Testing before shipping

-

Step 1: Size Detection

-

Step 2: GO Gauge and NO-GO Gauge Detection

-

Step 3: Chemical Composition Detection

-

Step 4: Mechanical Properties Test

-

Step 5: The product is carefully packaged

-

Why Choose JM Hardware® as Your Super Duplex Stainless Steel Manufacturer?

- Industry Expertise: Over 18 years of experience in manufacturing high-performance fasteners and components.

- Custom Solutions: Tailored products to meet your unique requirements.

- Wide Range of Products: From bolts and nuts to custom-designed components, we have you covered.

- Global Shipping: On-time delivery to projects around the world.

- Uncompromising Quality: Rigorous testing ensures every product meets the highest standards.

- Competitive Pricing: High-quality products at competitive rates to support your business goals.

- Sustainable Practices: Commitment to eco-friendly manufacturing and recyclable materials.

Contact JM Hardware® for Your Super Duplex Stainless Steel Needs

When it comes to high-performance, reliable, and precision-engineered fasteners, JM Hardware® is your trusted Super Duplex Stainless Steel Manufacturer. Whether you need custom solutions or standard components, we are here to support your projects with the best products and services.

Contact us today to discuss your requirements or request a quote. Let us be your partner in delivering excellence for your industrial applications!

Duplex stainless steels are usually selected for their high mechanical properties and good to very high corrosion resistance (particularly to stress corrosion cracking).

Oil and Gas:

a wide range of equipment: flowlines, manifolds, risers, pumps, valves, etc.

Pulp and Paper:

digesters, pressure vessels, liquor tanks, etc.

Chemical engineering:

pressure vessels, heat exchangers, condensers, distillation columns, agitators, marine chemical tankers, etc.

Water:

desalination plants, large tanks for water storage, waste water treatment

renewable energy: Biogas tanks

Mobility: tramcars and bus frames, tank trucks, iron ore wagons

Engineering: pumps, valves, fittings, springs, etc.