-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing Hastelloy C-22 fasteners, renowned for their exceptional performance in highly corrosive environments. As a leading Hastelloy C-22 fastener manufacturer, we are committed to providing top-quality solutions tailored to the unique needs of industries such as chemical processing, petrochemicals, and marine engineering. Our advanced manufacturing processes, strict quality control, and ability to deliver custom solutions make us your trusted partner for all Hastelloy B-3 fastener needs.

Hastelloy C-22 is a versatile Ni-Cr-Mo-W alloy with better comprehensive corrosion resistance performance than other Ni-Cr-Mo alloys, including Hastelloy C276, Hastelloy C4 and Inconel 625. Hastelloy C-22 has a outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It has a excellent resistance to oxidizing aqueous media including wet chlorine , mixtures containing nitric acid or oxidizing acids with chloride ions. Hastelloy C22 also offers optimum resistance to environments oxidiic conditions. With these feature, Hastelloy C22 can be used in hostile conditions. Hastelloy C-22 also has exceptional resistance to a wide variety of chemical process environments, such as ferric and cupric chlorides, chlorine, hot contaminated solutions (organic and inorganic), formic and acetic acids, acetic anhydride, and seawater and brine solutions. It resists the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition.

Different Countries Steel No. Chart

| Model | GB | ASTM | DIN | BS | AFNOR | |

| New grades | Old grades | |||||

| Hastelloy C-276 | NS3304 | NS334 | UNS N10276 | W.Nr.2.4819 / NiMo16Cr15W | NC17D | |

| Hastelloy C-4 | 2.461 | |||||

| Hastelloy C-22 | NS3308 | UNS N06022 | W.Nr.2.4602 | |||

| Hastelloy C-2000 | UNS N06200 | 2.4675 | ||||

| Hastelloy C-59 | UNS N06059 | 2.4605 | ||||

| Hastelloy B | NS3201 | NS321 | UNS N10001 | |||

| Hastelloy B-2 | NS3202 | NS322 | UNS N10665 | 2.46 | NiMo28 | |

| Hastelloy B-3 | NS3203 | UNS N10675 | 2.46 | |||

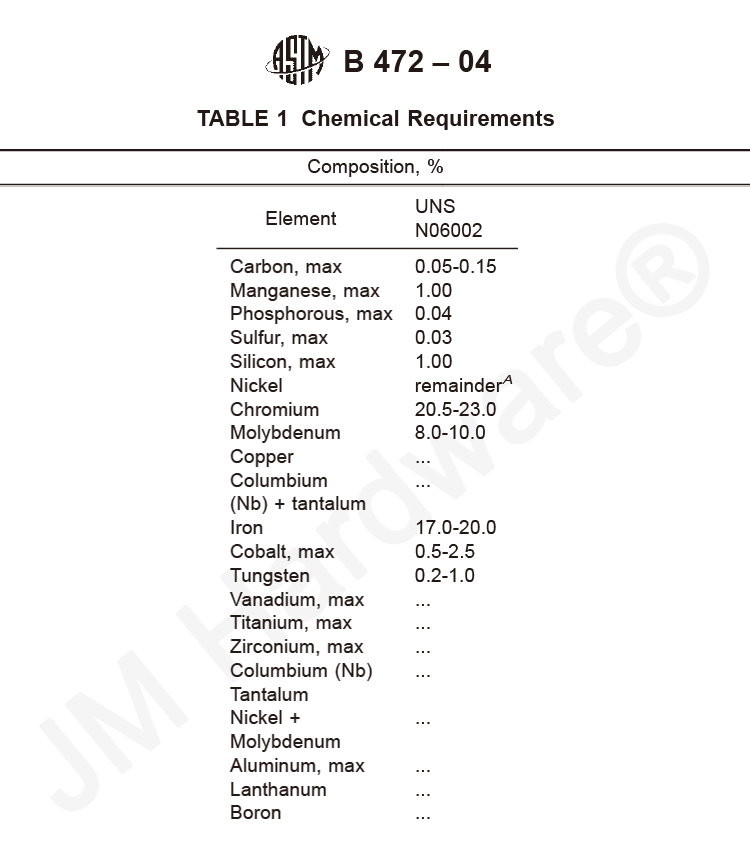

| Hastelloy X | UNS N06002 | 2.4665 | ||||

Forms of Hastelloy C-22 Fastener Available at JM Hardware®

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

Hastelloy C-22 Chemical composition:

| Alloy | % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S |

| C | Min. | balance | 14.5 | 15 | 4 | 3 | |||||||

| Max. | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.08 | 1 | 1 | 0.35 | 0.04 | 0.03 | ||

| C22 | Min. | balance | 20 | 12.5 | 2 | 2.5 | |||||||

| Max. | 22.5 | 14.5 | 6 | 3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.35 | 0.02 | 0.02 |

Hastelloy C-22 Physical properties:

| Density | 8.9 g/cm³ |

| Melting point | 1325-1370 ℃ |

Hastelloy C-22 Alloy m inimum mechanical properties in the roomtemperature:

| Alloy state | Tensile strength Rm N/mm² | Yield strength R P0. 2N/mm² | Elongation A 5 % |

| Hastelloy C-22 | 690 | 283 | 40 |