-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a leading Hyper Duplex Stainless Steel fastener manufacturer, offering premium-quality fasteners that meet the demanding needs of industries such as oil & gas, chemical processing, desalination, and marine engineering. Hyper Duplex Stainless Steel fasteners are specifically designed to provide superior mechanical properties, exceptional corrosion resistance, and unmatched performance in the most extreme environments. With our expertise and advanced manufacturing capabilities, we deliver fastener solutions that exceed expectations for durability and reliability.

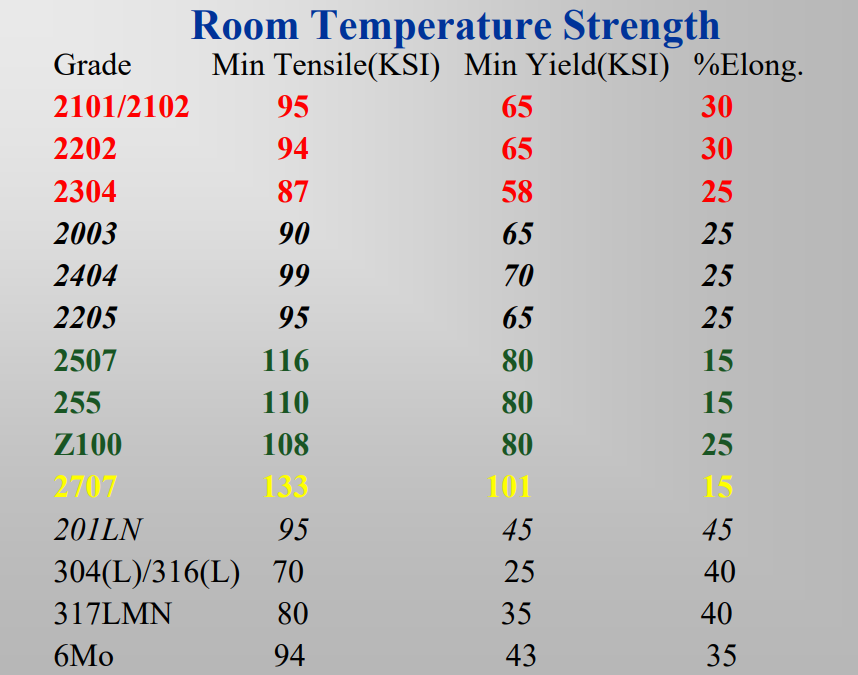

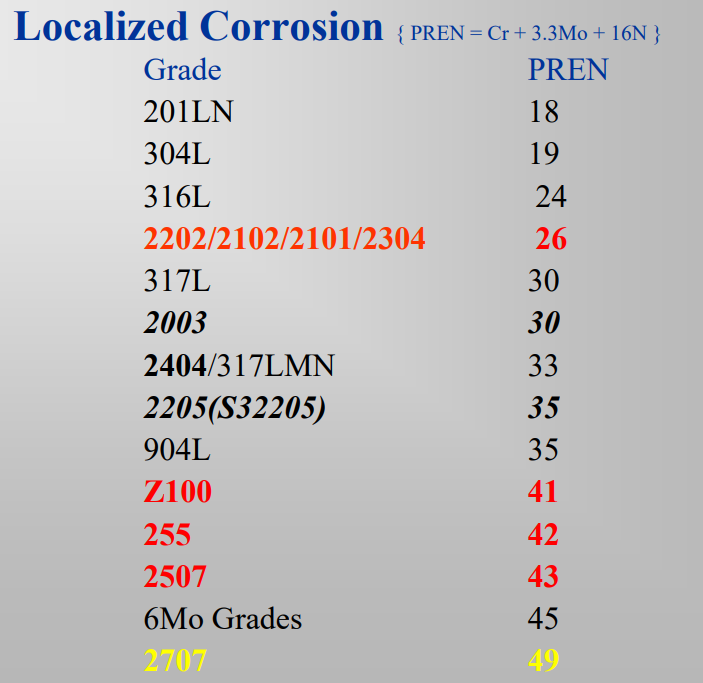

Typically grade EN 1.4410 up to so-called hyper duplex grades (PREN: >45) developed later to meet specific demands of the oil and gas as well as those of the chemical industries. They offer a superior corrosion resistance and strength but are more difficult to process because the higher contents of Cr, Mo, N and even W promote the formation of intermetallic phases, which reduce drastically the impact resistance of the steel. Faulty processing will result in poor performance and users are advised to deal with reputable suppliers/processors.Applications include deepwater offshore oil production.

| Lean Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| 2101 | S32101 | 1.4162 | 0,04 | 21,0-22,0 | 1,35-1,7 | 0,1 – 0,8 | 0,20-0,25 | 4,0-6,0 | 0,1-0,8 | – | 26 | |

| F66 | 2202 | S32202 | 1.4062 | 0,03 | 21,5-24,0 | 1,0-2,8 | 0,45 | 0,18-0,26 | 2,0 | – | 26 | |

| F68 | 2304 | S32304 | 1.4362 | 0,03 | 21,5-24,5 | 3,0-5,5 | 0,05-0,6 | 0,05-0,20 | 2,5 | 0,05-0,60 | – | 26 |

| 2102 | S82011 | 0,03 | 20.5-23.5 | 1.00-2.00 | 0,1 – 1.00 | 0.15-0.27 | 2.00-3.00 | 0.5 | – | 26 | ||

| Standard Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| F51 | 2205 | S31803 | 1.4462 | 0,03 | 21,0-23,0 | 4,5-6,5 | 2,5-3,5 | 0,08-0,20 | 2,0 | – | – | 33 |

| F60 | 2205 | S32205 | 1.4462 | 0,03 | 22,0-23,0 | 4,5-6,5 | 3,0-3,5 | 0,14-0,20 | 2,0 | – | – | 35 |

| 2003 | S32003 | 1.4662 | 0,03 | 19.5-22.5 | 3.0-4.0 | 1.5-2.0 | 0.14-0.2 | 2,0 | – | – | 30 | |

| 2404 | S82441 | 1.4662 | 0,03 | 23.0-25.0 | 3.0-4.5 | 1.00-2.00 | 0.20-0.30 | 2.5-4.0 | 0.10-0.80 | – | 33 | |

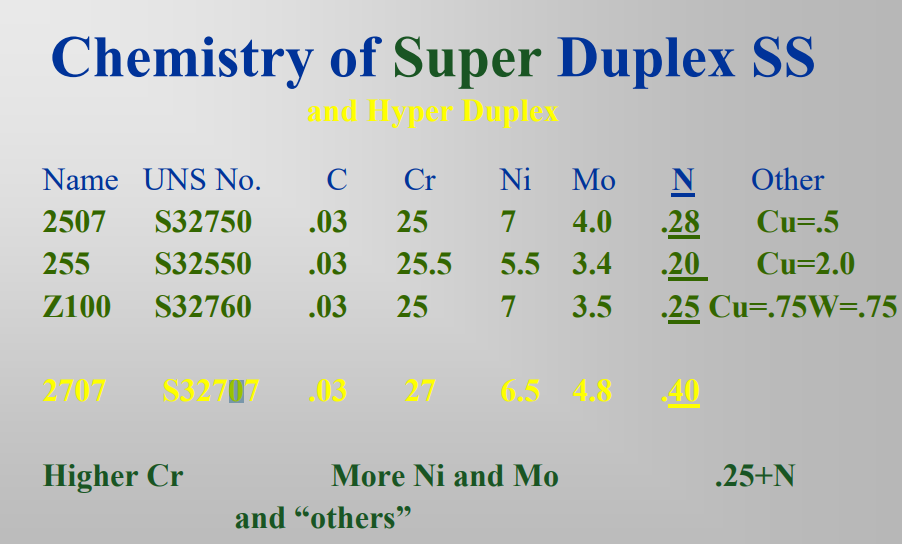

| Super Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| F59 | S32520 | 1.4507 | 0,03 | 24,0-26,0 | 5,5-8,0 | 3,0-4,0 | 0,20-0,35 | 1,5 | 0,5-2,0 | – | >40 | |

| F61 | 255 | S32550 | 1.4507 | 0,04 | 24,0-27,0 | 4,5-6,5 | 2,9-3,9 | 0,10-0,25 | 1,5 | 1,5-2,5 | – | >40 |

| F53 | 2507 | S32750 | 1.441 | 0,03 | 24,0-26,0 | 6,0-8,0 | 3,0-5,0 | 0,24-0,32 | 1,2 | 0,50 | – | 43 |

| F55 | Z100 | S32760 | 1.4501 | 0,03 | 24,0-26,0 | 6,0-8,0 | 3,0-4,0 | 0,20-0,30 | 1,0 | 0,5-1,0 | 0,5-1,0 | 42 |

| Hyper Duplex | ||||||||||||

| Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* | |

| 2707 | S32707 | – | 0,03 | 26,0-29,0 | 5,5-9,5 | 4,0-5,0 | 0,30-0,50 | 1,5 | 1,00 | – | 49 | |

| 3207 | S33207 | – | 0,03 | 29,0-33,0 | 6,0-9,0 | 3,0-5,0 | 0,40-0,60 | 1,5 | 1,00 | – | 50 | |

| Austenitic Grades | ||||||||||||

| ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn | Cu | W | PRE* | ||

| 304L | 1.4307 | 0,03 | 17,5-19,5 | 8,0-10,5 | – | 0,11 | – | – | – | 18 | ||

| 316L | 1.4404 | 0,03 | 16,5-18,5 | 10,0-13,0 | 2,0-2,5 | 0,10 | – | – | – | 24 | ||

| 904L | 1.4539 | 0,02 | 19,0-21,0 | 24,0-26,0 | 4,0-5,0 | 0,15 | – | 1,20 | – | 34 | ||

| S31254 | 1.4547 | 0,2 | 19,5-20,5 | 17,5-18,5 | 6,0-7,0 | 0,18-0,25 | – | 0,5-1,0 | – | 43 | ||

Forms of Hyper Duplex SS Fastener Available at JM Hardware®

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Oil and Gas:

a wide range of equipment: flowlines, manifolds, risers, pumps, valves, etc.

Pulp and Paper:

digesters, pressure vessels, liquor tanks, etc.

Chemical engineering:

pressure vessels, heat exchangers, condensers, distillation columns, agitators, marine chemical tankers, etc.

Water:

desalination plants, large tanks for water storage, waste water treatment

renewable energy: Biogas tanks

Mobility: tramcars and bus frames, tank trucks, iron ore wagons

Engineering: pumps, valves, fittings, springs, etc.