-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we take pride in being a leading Hastelloy C-4 fastener manufacturer, offering premium-quality fasteners designed to meet the most demanding industrial requirements. Known for their exceptional resistance to corrosion, thermal stability, and chemical attacks, Hastelloy C-4 fasteners are the go-to choice for industries operating in highly aggressive environments. With decades of experience and advanced manufacturing expertise, we provide tailored solutions for B2B customers across various sectors, including chemical processing, power generation, marine, and aerospace.

Hastelloy C4 has a excellent heat stability and tenacity at a high temperature. It also possess excellent resistance to stress-corrosion cracking and oxidizing atmospheres up to 1040℃. Hastelloy C4 has a exceptional resistance to a wide variety of chemical process environment, including hot contaminated mineral acids, solvents, chlorine and chlorine contaminated media (organic and inorganic), formic and acetic acids, acetic anhydride, and seawater and brine solutions.

Different Countries Steel No. Chart

| Model | GB | ASTM | DIN | BS | AFNOR | |

| New grades | Old grades | |||||

| Hastelloy C-276 | NS3304 | NS334 | UNS N10276 | W.Nr.2.4819 / NiMo16Cr15W | NC17D | |

| Hastelloy C-4 | 2.461 | |||||

| Hastelloy C-22 | NS3308 | UNS N06022 | W.Nr.2.4602 | |||

| Hastelloy C-2000 | UNS N06200 | 2.4675 | ||||

| Hastelloy C-59 | UNS N06059 | 2.4605 | ||||

| Hastelloy B | NS3201 | NS321 | UNS N10001 | |||

| Hastelloy B-2 | NS3202 | NS322 | UNS N10665 | 2.46 | NiMo28 | |

| Hastelloy B-3 | NS3203 | UNS N10675 | 2.46 | |||

| Hastelloy X | UNS N06002 | 2.4665 | ||||

Forms of Hastelloy C-4 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

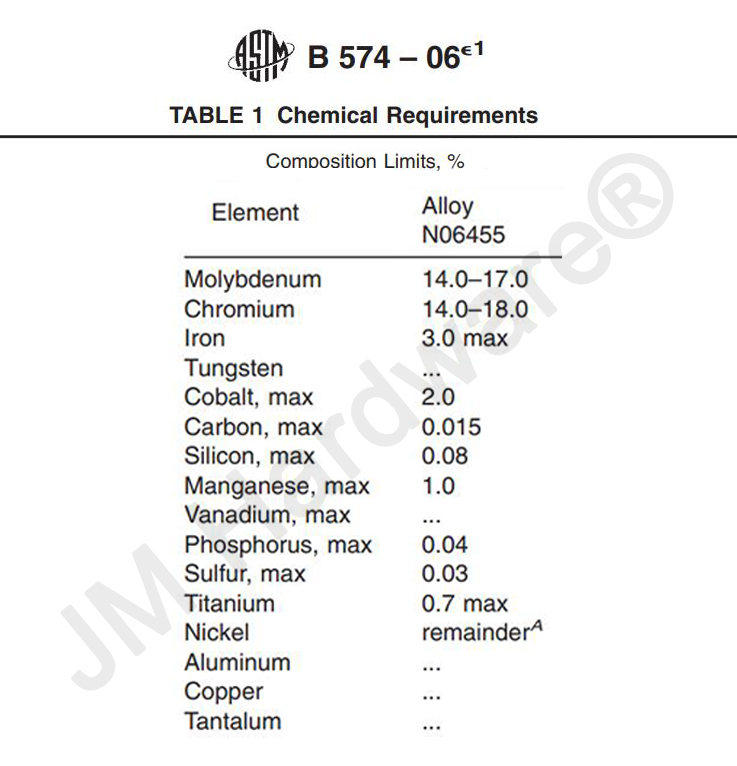

| Hastelloy C4 Chemical compostion: | ||||||||||||

|

Alloy

|

% | Ni | Cr | Mo | Fe | C | Mn | Si | Co | S | P | Ti |

| C-4 | Min. | 65 | 14 | 14 | ||||||||

| Max. | 18 | 17 | 3 | 0.01 | 1 | 0.08 | 2 | 0.01 | 0.025 | 0.7 | ||

| Hastelloy C4 Physical properties: | |

|

Density

|

8.64 g/cm3 |

| Melting point | 1350-1400 ℃ |

| Hastelloy C4 Alloy minimum mechanical properties in the room temperature: | |||

|

Alloy

|

Tensile strength Rm N/mm2 | Yield strength RP0.2N/mm2 | Elongation A5 % |

| C-4 | 783 | 365 | 55 |