-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing Hastelloy B-2 fasteners, tailored for industries that require superior corrosion resistance and durability. Known for their exceptional performance in harsh environments, Hastelloy B-2 fasteners are widely used in chemical processing, power generation, marine, and other demanding applications. As a trusted Hastelloy fastener manufacturer, we combine advanced technology, premium materials, and rigorous quality control to deliver reliable fastening solutions that meet the most stringent industry standards.

Hastelloy B has good corrosion resistance to reducing environments such as moderate concentrations of sulfuric acid and other non-oxidizing acids, and is very resistant to chloride ion stress corrosion cracking, but is highly susceptible to corrosion by oxidizing environments and cannot be used. In environments containing iron or copper salts, these materials can cause corrosion quickly.

Different Countries Steel No. Chart

| Model | GB | ASTM | DIN | BS | AFNOR | |

| New grades | Old grades | |||||

| Hastelloy C-276 | NS3304 | NS334 | UNS N10276 | W.Nr.2.4819 / NiMo16Cr15W | NC17D | |

| Hastelloy C-4 | 2.461 | |||||

| Hastelloy C-22 | NS3308 | UNS N06022 | W.Nr.2.4602 | |||

| Hastelloy C-2000 | UNS N06200 | 2.4675 | ||||

| Hastelloy C-59 | UNS N06059 | 2.4605 | ||||

| Hastelloy B | NS3201 | NS321 | UNS N10001 | |||

| Hastelloy B-2 | NS3202 | NS322 | UNS N10665 | 2.46 | NiMo28 | |

| Hastelloy B-3 | NS3203 | UNS N10675 | 2.46 | |||

| Hastelloy X | UNS N06002 | 2.4665 | ||||

Forms of Hastelloy B-2 Fastener Available at JM Hardware®

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

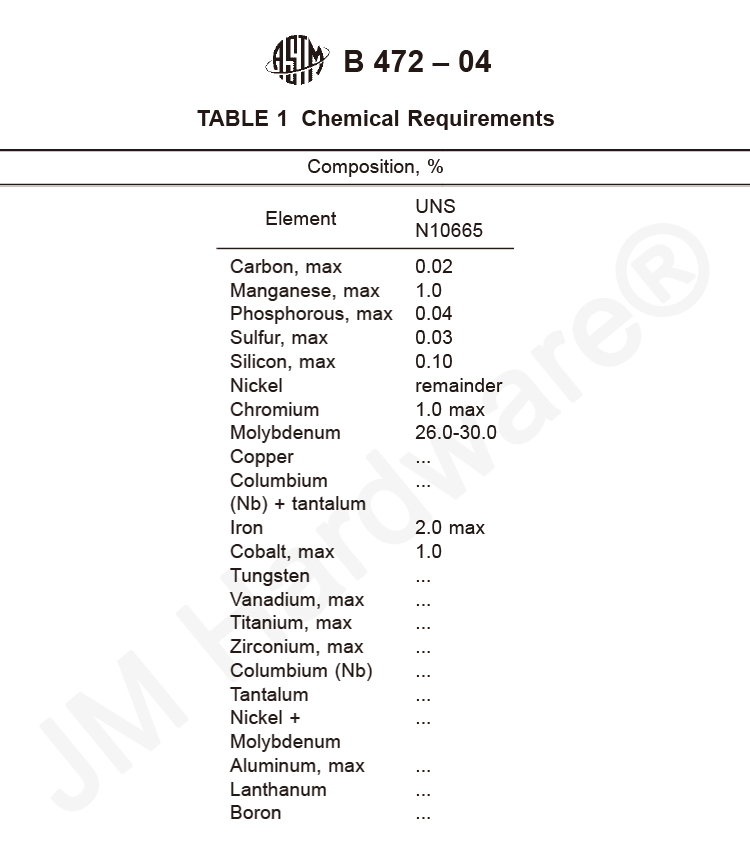

| Hastelloy B-2 Chemical compostion: | ||||||||||||

|

Alloy

|

% | Ni | Mo | Fe | Cr | Co | C | Mn | V | Si | P | S |

| Hastelloy B | Min. | Balance | 26 | 4 | 0.2 | |||||||

| Max. | 30 | 6 | 1 | 2.5 | 0.05 | 1 | 0.4 | 1 | 0.04 | 0.03 | ||

| Hastelloy B-2 | Min. | Balance | 26 | 2 | ||||||||

| Max. | 30 | 7 | 1 | 1 | 0.02 | 1 | 0.1 | 0.04 | 0.03 | |||

| Hastelloy B-2 Physical properties: | |

|

Density

|

9.24g/cm3 |

| Melting point | 1330-1380℃ |

| Hastelloy B-2 Alloy minimum mechanical properties in the room temperature: | |||

|

Alloy state

|

Tensile strength | Yield strength | Elongation A5 % |

| Rm N/mm2 | RP0.2N/mm2 | ||

| Hastelloy B | 690 | 310 | 40 |