-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing Hastelloy C-59 fasteners, renowned for their exceptional performance in highly corrosive environments. As a leading Hastelloy C-59 fastener manufacturer, we are committed to providing top-quality solutions tailored to the unique needs of industries such as chemical processing, petrochemicals, and marine engineering. Our advanced manufacturing processes, strict quality control, and ability to deliver custom solutions make us your trusted partner for all Hastelloy C-59 fastener needs.

Hastelloy C-59 / N06059 / NS3311 / ALLOY 59 / 2.4605

The chemically stable and high-temperature resistant nickel and cobalt alloy 2.4605 (alloy 59) is mainly used in the chemical industry, flue gas desulphurisation plants, paper industry.

Alloy 59 is a nickel-chromium-molybdenum alloy with excellent corrosion resistance and high mechanical strength. The alloy has excellent resistance to both oxidizing and reducing media, and possesses superior resistance to chloride pitting and stress corrosion cracking.

Different Countries Steel No. Chart

| Model | GB | ASTM | DIN | BS | AFNOR | |

| New grades | Old grades | |||||

| Hastelloy C-276 | NS3304 | NS334 | UNS N10276 | W.Nr.2.4819 / NiMo16Cr15W | NC17D | |

| Hastelloy C-4 | 2.461 | |||||

| Hastelloy C-22 | NS3308 | UNS N06022 | W.Nr.2.4602 | |||

| Hastelloy C-2000 | UNS N06200 | 2.4675 | ||||

| Hastelloy C-59 | UNS N06059 | 2.4605 | ||||

| Hastelloy B | NS3201 | NS321 | UNS N10001 | |||

| Hastelloy B-2 | NS3202 | NS322 | UNS N10665 | 2.46 | NiMo28 | |

| Hastelloy B-3 | NS3203 | UNS N10675 | 2.46 | |||

| Hastelloy X | UNS N06002 | 2.4665 | ||||

Forms of Hastelloy C-59 Fastener Available at JM Hardware®

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

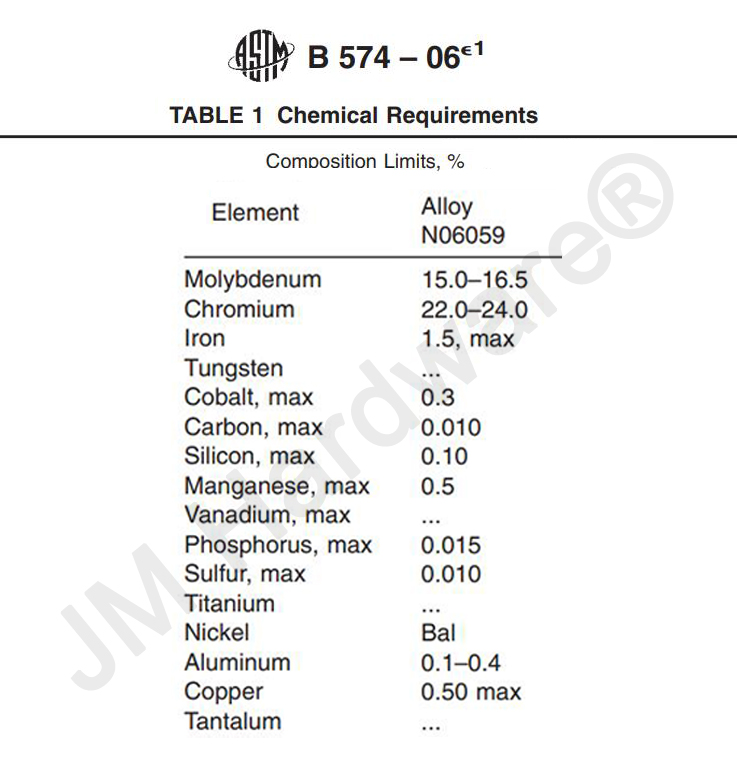

| Hastelloy C-59 Chemical Composition (% by weight): | ||

|

Element

|

Min | Max |

| C | - | 0.001 |

| Si | - | 0.1 |

| Mn | - | 0.5 |

| P | - | 0.015 |

| S | - | 0.01 |

| Al | 0.1 | 0.4 |

| Co | - | 0.3 |

| Cr | 22 | 24 |

| Cu | - | 0.5 |

| Fe | - | 1.5 |

| Mo | 15 | 16.5 |

| Ni | Balance | |

| Hastelloy C-59 Mechanical Properties: | ||

|

Temper

|

Annealed | |

| Tensile Rm | 100 | ksi (min) |

| Tensile Rm | 690 | MPa (min) |

| R.p. 0.2% Yield | 45 | ksi (min) |

| R.p. 0.2% Yield | 310 | MPa (min) |

| Elongation (2” or 4D gl) | 40 | % (min) |