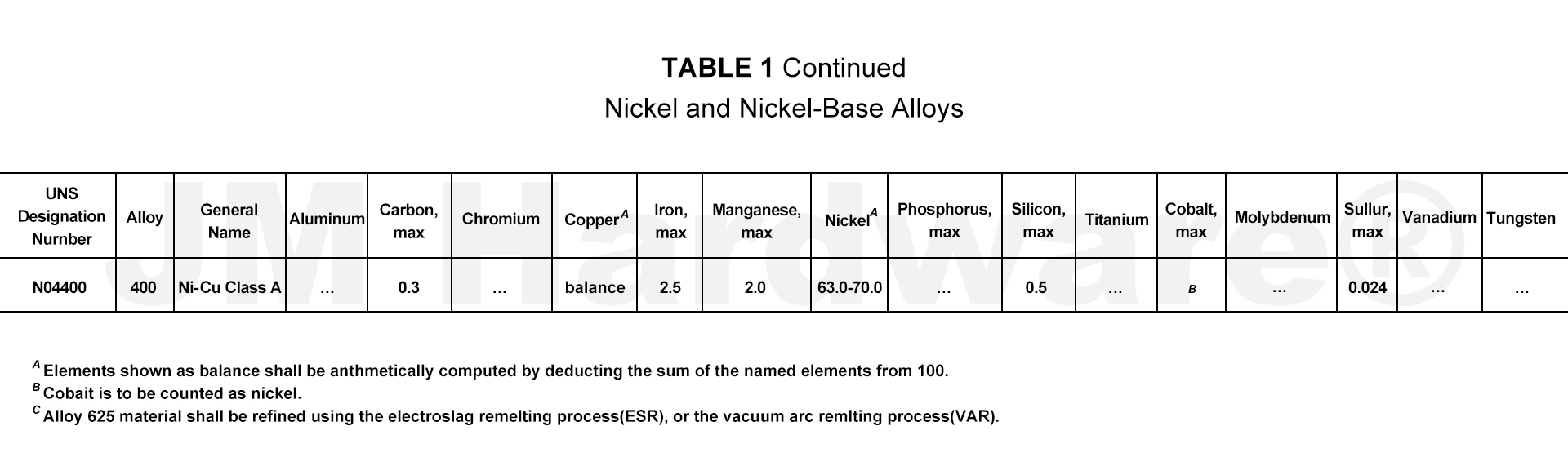

-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

JM Hardware®'s Monel 400 fasteners are tailor-made for environments where corrosion poses a significant challenge. From bolts to nuts, screws to washers, our Monel 400 Alloy Fasteners offer exceptional performance, ensuring longevity and reliability in critical applications. Industries such as marine, chemical processing, and oil and gas benefit from the unparalleled corrosion resistance and high strength of our Monel 400 fasteners.

Choose JM Hardware® for a trusted partner in securing your projects with Monel 400 Alloy Fasteners – a symbol of resilience and quality that defines our commitment to excellence.

Nickel Alloy 400/ Monel 400 Bolts and Nuts and Nuts

A nickel-copper alloy, Monel 400 bolts are a solid solution nickel alloy that can only be hardened by cold working. Best known for its corrosion resistance to reducing media and seawater, Monel 400 is also tougher in oxidizing environments than copper alloys. Also known as alloy 400, Monel 400 bolts are also utilized in high temperature, caustic and salt solution applications.

High and Low Temperature Properties

Used for high temperature applications up to 1000°F in oxidizing atmospheres, Monel 400 bolts can also be used at higher temperatures if in a reducing environment. Though commonly used at high temperatures, Monel 400 bolts also retain their mechanical properties at subzero temperatures. Increased hardness at freezing temperatures has been shown to only slightly impair the ductility or impact resistance of Monel 400 bolts. Even when cooled to the temperature of liquid hydrogen, Monel 400 does not undergo a ductile-to-brittle transition which can cause fractures. This is especially unique compared to most ferrous materials which are often stronger, yet very brittle at extreme low

Renowned Seawater Resistance

Perhaps the best attribute of Monel 400 bolts is their ability to defy seawater corrosion. Uniquely, they offer resistance to rapidly moving seawater, which can erode other materials, though stagnant salt water situations can sometimes result in crevice and pitting corrosion. In addition, Monel 400 bolts prevent stress corrosion cracking and pitting in most fresh and industrial waters.

General Corrosion Protection

Though it is best known for its resistance to sea water, Monel 400 bolts also show good resistance reducing media. It also resists oxidizing media better than many alloys with higher copper content. When it comes to acids, Monel 400 bolts offer very good protection from hydrofluoric acid in all concentrations up to the boiling point, as well as decent protection to sulfuric and hydrochloric acids under reducing conditions.

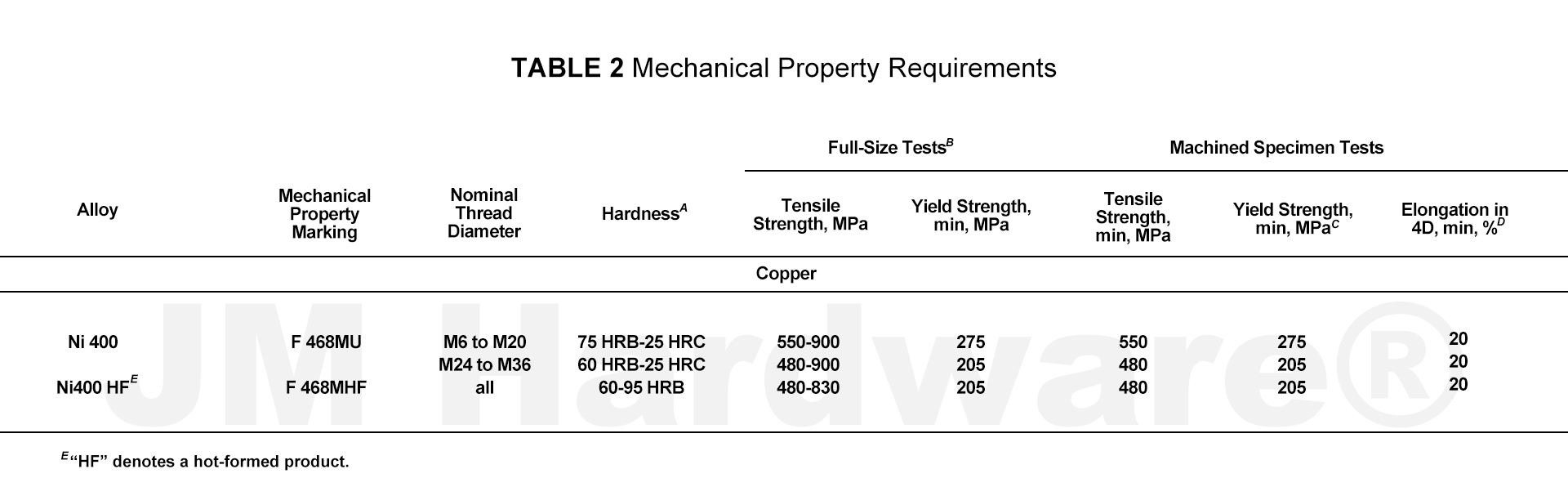

The mechanical properties of Monel 400 fasteners are as follows

The mechanical properties of Monel 400 fasteners are as follows

Forms of Monel 400 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6923 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping