-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

JM Hardware® INCONEL 718 - AMS 5596 - UNS N07718 ALLOY Fastener

INCONEL 718 is a precipitation-hardening, nickel-chromium alloy with excellent mechanical properties even at elevated temperatures. Its composition includes significant amounts of nickel, chromium, and molybdenum, along with niobium, iron, and lesser quantities of other elements. This meticulous blend engenders remarkable resistance to corrosion, oxidation, and high-temperature degradation.

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Description

Inconel 718 is a nickel-chromium-molybdenum alloy designed to resist a wide range of severely corrosive environments, pitting and crevice corrosion. This nickel steel alloy also displays exceptionally high yield, tensile, and creep-rupture properties at high temperatures. This nickel alloy is used from cryogenic temperatures up to long term service at 1200° F. One of the distinguishing features of Inconel 718’s composition is the addition of niobium to permit age hardening which allows annealing and welding without spontaneous hardening during heating and cooling.

| INCONEL | |||

| Raw Material | Unified Numbering System (UNS) | DIN EN | Common Trade Name |

| Inconel Alloy 600 | N06600 | 2.4816 | Inconel® 600 |

| Inconel 600 Specifications: UNS N06600, AMS 5540, AMS 5665, ASME SB-166, ASME SB-167, ASME SB-168, ASTM B166, ASTM B167, ASTM B168, DIN EN 2.4816 | |||

| Inconel Alloy 601 | N06601 | 2.4851 | Inconel® 601 |

| Inconel 601 Specifications: UNS N06601, AMS 5715, AMS 5870, ASME SB-167, ASME SB-168, ASTM B167, ASTM B168, DIN EN 2.4851 | |||

| Inconel Alloy 625 | N06625 | 2.4856 | Inconel® 625 |

| Inconel 625 Specifications: UNS N06625, AMS 5666, AMS 5837, ASME SB-443 Gr 1, ASME SB-446 Gr 1, ASTM B443 Gr 1, ASTM B446 Gr 1, ISO 15156-3, NACE MR0175-3, DIN EN 2.4856 | |||

| Inconel Alloy 718 | N07718 | 2.4668 | Inconel® 718 |

| Inconel 718 Specifications: UNS N07718, AMS 5596, AMS 5662, AMS 5663, AMS 5832, ASME Case 2222-1, ASME SFA 5.14, ASTM B637, ASTM B670, GE B50TF14, GE B50TF15, DIN EN 2.4668 | |||

Forms of INCONEL 718 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

Step 1: Size Detection

Step 2: GO Gauge and NO-GO Gauge Detection

Step 3: Chemical Composition Detection

Step 4: Mechanical Properties Test

Step 5: The product is carefully packaged

TECHNICAL DATA

| Specifications | |

|

Form

|

Standard |

| Metal Type | UNS N07718 |

| Bar | ASTM B637 AMS 5662 AMS 5663 AMS 5664 PWA 1009 PWA 1010 GE B50TF15 |

| Wire | AMS 5832 |

| Sheet | ASTM B670 AMS 5596 AMS 5597 PWA 1033 GE B50TF14 ASTM B670 ASTM B637 |

| Plate | ASTM B670 AMS 5596 AMS 5597 PWA 1033 GE B50TF15 ASTM B670 ASTM B637 |

|

Tube

|

AMS 5589 AMS 5590

|

|

Pipe

|

AMS 5589 AMS 5590

|

| Fitting | |

| Forging | ASTM B637 AMS 5562 AMS 5663 AMS 5664 PWA 1009 PWA 1010 GE B50TF15 |

| Weld Wire | A5.14 ERNiFeCr-2 |

|

Weld Electrode

|

|

| Din | 2.4668 |

|

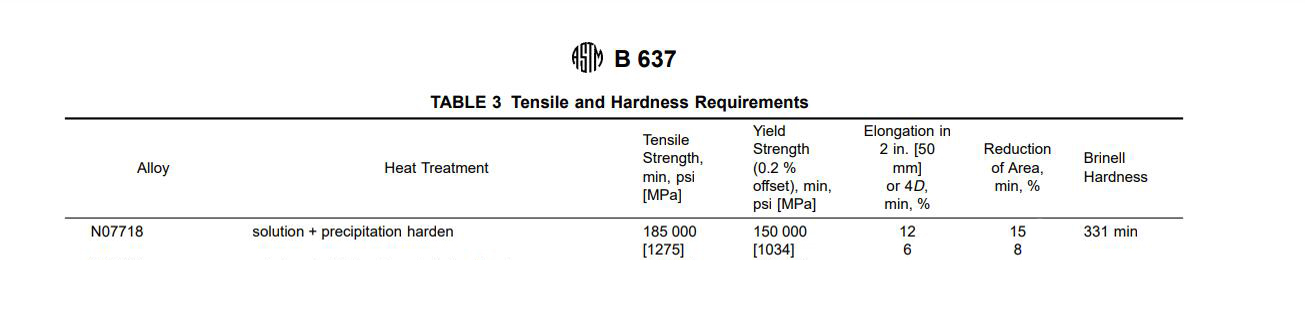

Mechanical Property Requirements

|

|||||

| Ultimate Tensile | Yield Strength (0.2% OS) | Elong. in 2 in. (50mm) or 4D min, % | R/A | Hardness Brinell | |

| Min | 185 KSi | 150 KSi | 12 | 15 | 331 |

| Max | |||||

| Min | 1275 MPa | 1034 MPa | |||

| Max | |||||

|

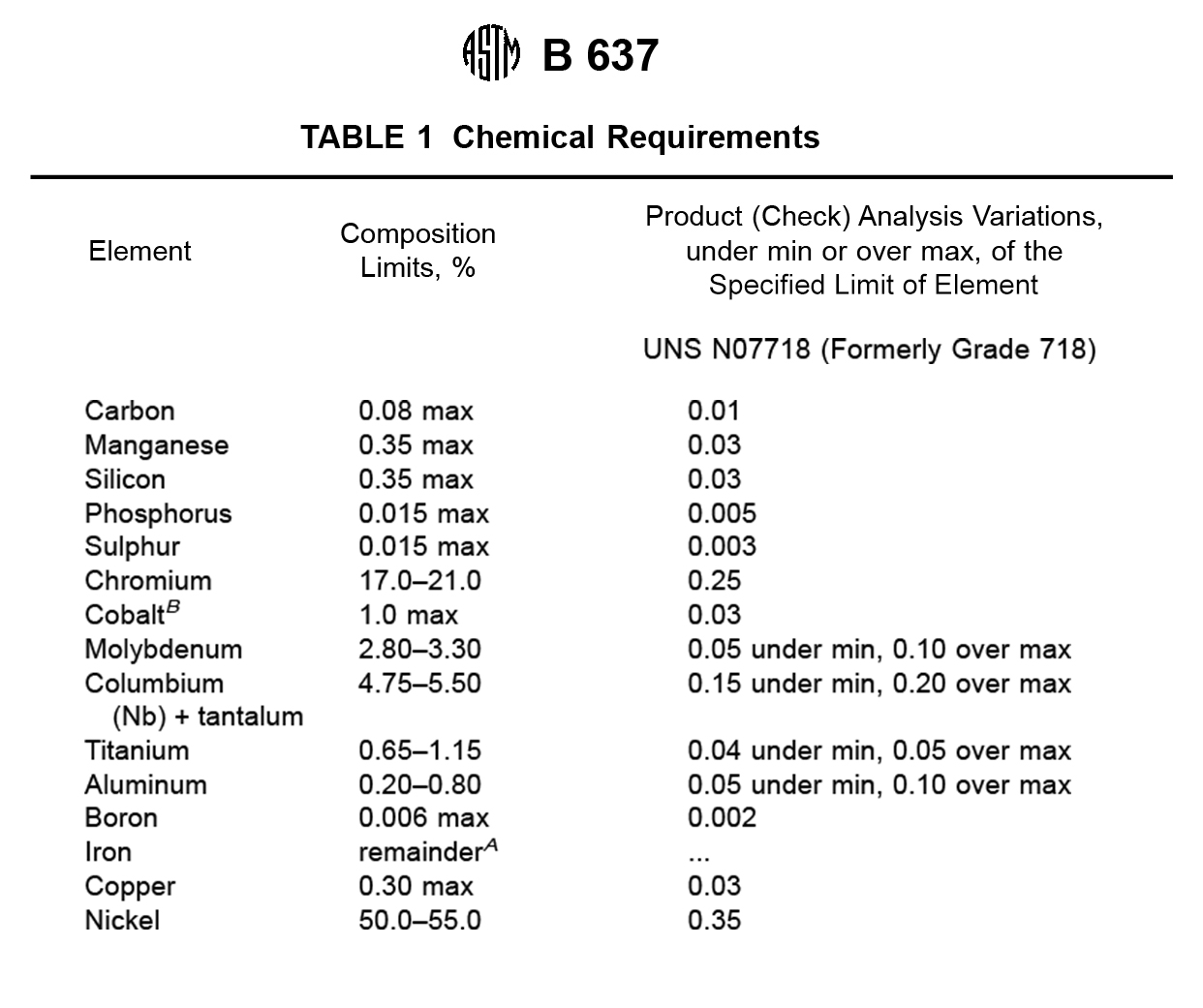

Chemical Requirements

|

|||||||

| Ni | Fe | Mo | Mn | Si | Cr | C | |

| Max | 55 | Bal | 3.3 | 0.35 | 0.35 | 21 | 0.08 |

| Min | 50 | 2.8 | 17 | ||||