-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a trusted Tower Bolt Manufacturer, providing a wide range of tower bolts that meet the demands of construction, industrial, and infrastructure projects. Tower bolts are widely used for structural stability, security, and durability, offering versatility in their application across different industries. With precision manufacturing, customizable solutions, and advanced testing, we ensure that our tower bolts deliver exceptional quality and performance. Below, we explore everything you need to know about tower bolts and why JM Hardware® should be your go-to manufacturer.

What are Tower Bolts?

Tower bolts are unique fasteners designed to provide secure locking and fastening solutions. They consist of a long sliding bar and a guide for locking doors, panels, gates, or large structures. Tower bolts are widely known for their robust design and resistance to wear, making them ideal for heavy-duty applications. In addition to traditional sliding bolts, tower bolts are used in structural applications like telecom towers, utility poles, and various industrial setups requiring strength and security.

Key Features of Our Tower Bolts

-

High Load-Bearing Capacity

Designed to withstand heavy loads, providing structural security.

-

Precision Engineering

Manufactured to exact specifications for seamless installation and superior performance.

-

Corrosion Resistance

Coated with specialized finishes to protect against rust, especially in outdoor and high-humidity environments.

-

Durability

Made from high-strength materials to withstand wear and tear over long periods.

-

Customizable Designs

Available in a variety of sizes, lengths, materials, and finishes to meet your specific project requirements.

Materials Used in Tower Bolts

As a professional As a professional Tower Bolt Manufacturer, we offer bolts made from high-grade materials to suit different applications and environments:

-

Carbon Steel:

Known for its strength and cost-effectiveness, ideal for heavy-duty indoor applications.

-

Stainless Steel (SS304, SS316):

Offers excellent corrosion resistance, making it perfect for outdoor or coastal environments.

-

Aluminum:

Lightweight and corrosion-resistant, suitable for applications requiring reduced weight.

-

Brass:

Used for decorative and lightweight applications while providing good corrosion resistance.

-

Alloy Steel:

Provides enhanced strength and durability, perfect for critical infrastructure like towers and large gates.

-

Duplex Stainless Steel:

Combines superior strength and resistance to stress corrosion cracking, ideal for high-stress environments.

Surface Finishes for Tower Bolts

To ensure longevity and performance, JM Hardware® offers a range of surface finishes for tower bolts:

-

Zinc Plating:

Provides basic corrosion protection, suitable for light-duty applications.

-

Hot-Dip Galvanizing:

Offers superior corrosion resistance, ideal for outdoor and industrial environments.

-

Teflon Coating:

Reduces friction during installation and provides protection against chemicals.

-

Black Oxide Coating:

Provides a smooth, black finish for aesthetic purposes and moderate rust protection.

-

Powder Coating:

Adds durability and resistance to wear while enhancing the bolt’s appearance.

-

Electroplating:

Ensures a polished, decorative finish for bolts used in architectural applications.

-

Passivation:

.Enhances the corrosion resistance of stainless steel bolts by removing impurities.

Applications of Tower Bolts

Tower bolts are versatile fasteners that are widely used in various industries. Here are some of the most common applications:

-

Telecom Towers:

Securing structural components and connecting tower sections, ensuring stability under extreme weather conditions.

-

Construction

Used for structural connections in commercial and residential buildings, gates, and shutters.

-

Industrial Equipment

Locking heavy machinery components or fastening equipment enclosures securely.

-

Utility Pole Connections

Fastening cross arms and structural components in utility poles.

-

Agricultural Infrastructure

Used in fastening irrigation systems, greenhouses, and storage facilities.

-

Railway and Transport Projects

Fasteners for large gates, fencing, or transport infrastructure.

-

Doors and Gates

Popular for securing doors, windows, and gates in homes, offices, and factories.

-

Renewable Energy Structures

Fastening parts in wind turbines or solar panel installations.

Grades of Tower Bolts

Our tower bolts are available in various grades to meet the unique demands of your application. Some commonly used grades include:

-

Grade 4.8, 8.8, 10.9, and 12.9:

Carbon steel bolts for general to heavy-duty use.

-

ASTM A193 B7 and B16:

High-strength bolts for high-temperature and high-pressure environments.

-

A2-70 and A4-80:

Stainless steel grades designed for environments requiring superior corrosion resistance.

-

Custom Grades:

We can manufacture bolts to meet your specific requirements.

Standards for Tower Bolts

As a trusted Tower Bolt Manufacturer, we adhere to a variety of international standards to ensure precision, reliability, and compliance with global safety requirements:

-

DIN Standards

European standards for dimensions, materials, and mechanical properties.

-

ASTM Standards:

Covers mechanical properties and performance for critical applications.

-

ISO Standards:

Ensures consistency and compatibility for international projects.

-

BS Standards:

British standards for bolt dimensions and performance.

-

JIS Standards:

Japanese standards for industrial-grade tower bolts.

Testing and Quality Control

At JM Hardware®, we perform a wide range of tests to ensure the quality and reliability of our tower bolts:

-

Tensile Strength Testing:

To verify the load-carrying capacity of the bolts.

-

Corrosion Resistance Testing

Evaluates performance in harsh environmental conditions.

-

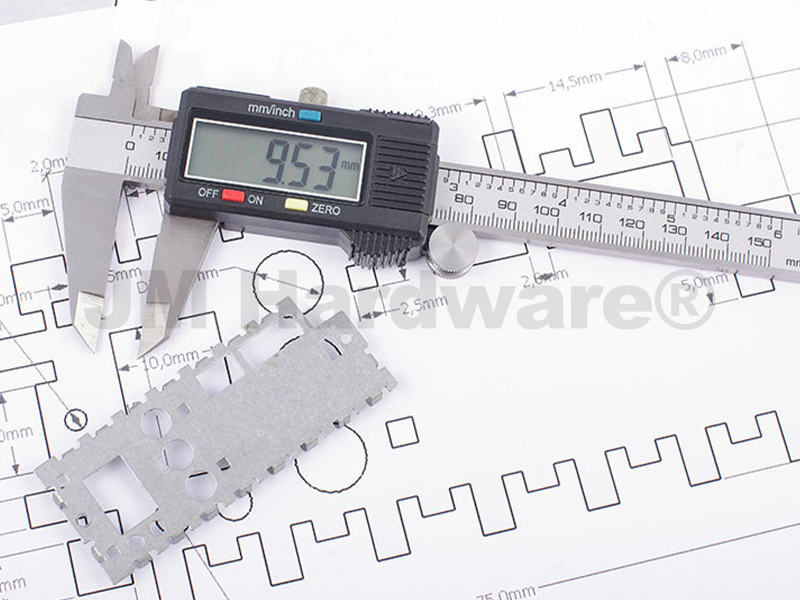

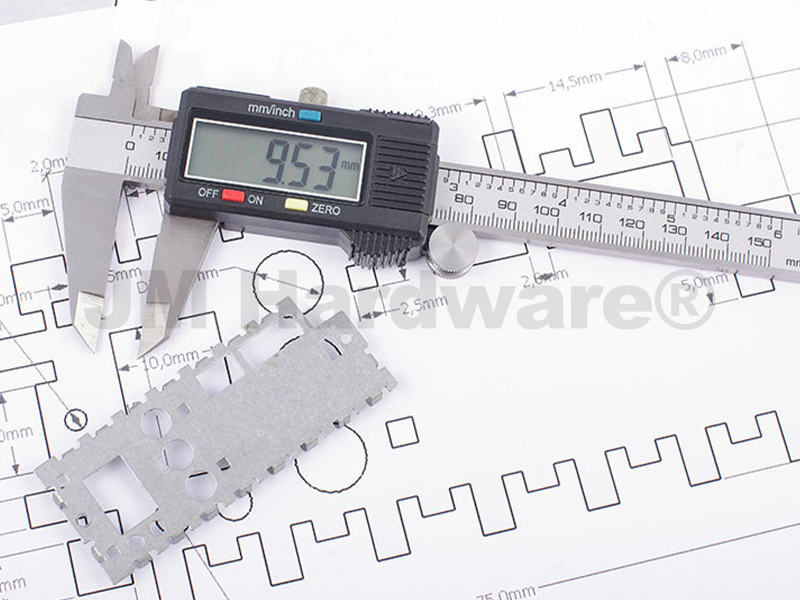

Dimensional Inspection:

Ensures precise dimensions and compatibility.

-

Impact Testing:

Ensures bolts can withstand shocks and vibrations.

-

Fatigue Testing:

Confirms the bolt’s performance under repeated stress cycles.

Production Process for Tower Bolts

Our advanced manufacturing process ensures precision and durability in every tower bolt we produce. The production stages include:

-

Raw Material Selection:

Only high-quality materials are used to ensure the bolts meet strict mechanical and chemical requirements.

-

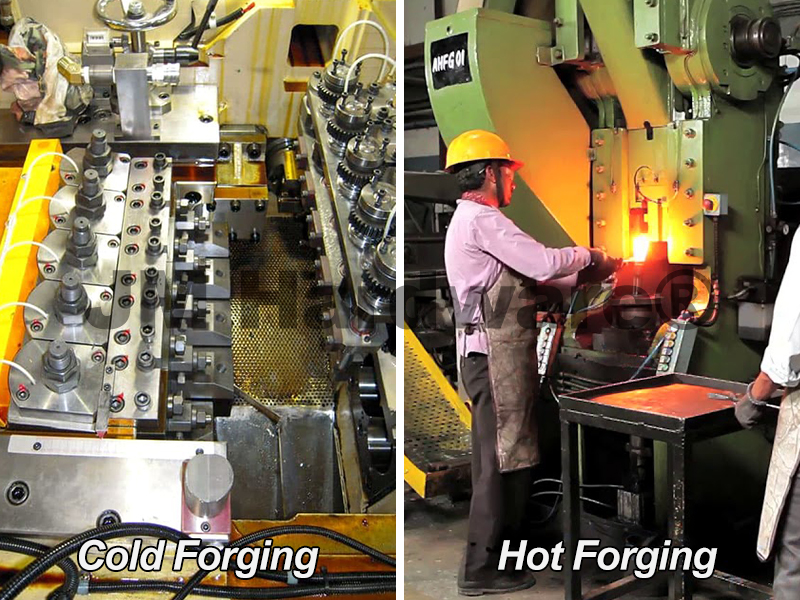

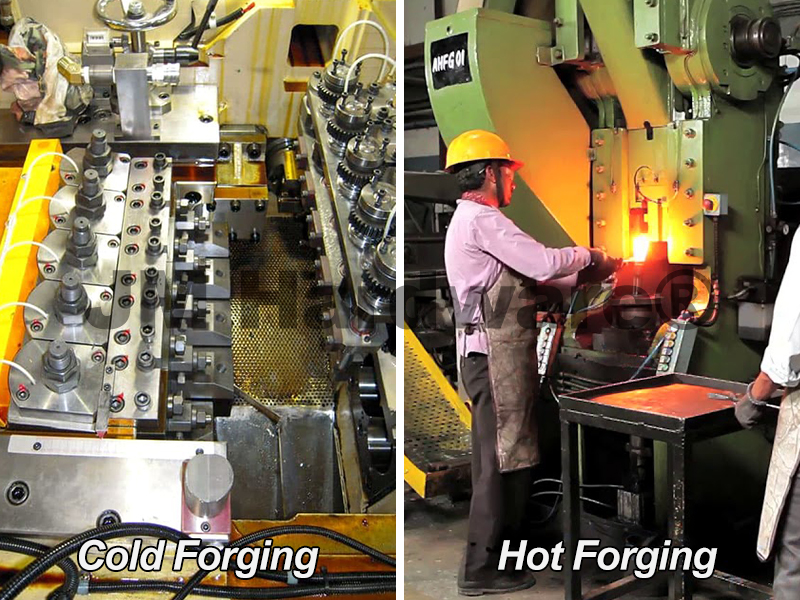

Cold or Hot Forging

The bolts are forged to achieve the desired strength and shape.

-

Thread Rolling:

Threads are rolled, not cut, to enhance strength and durability.

-

Heat Treatment:

Bolts are heat-treated to improve hardness and resistance to wear.

-

Surface Coating:

A protective layer is applied to improve corrosion resistance and appearance.

-

Precision Machinin:

Ensures dimensional accuracy and smooth finishes.

-

Quality Control:

Each bolt undergoes rigorous testing to ensure compliance with international standards.

Why Choose JM Hardware® as Your Tower Bolt Manufacturer?

1.Comprehensive Range: From telecom towers to residential gates, we offer tower bolts for every application.

2.Custom Solutions: Tailored designs, materials, and finishes to meet your unique requirements.

3.Premium Materials: High-quality materials ensure long-term performance and reliability.

4.Global Standards: Manufactured to meet DIN, ISO, ASTM, and other international standards.

5.Advanced Testing: Rigorous quality control ensures every bolt meets your expectations.

6.Fast Delivery: Efficient production and logistics guarantee on-time delivery for all orders.

Contact JM Hardware® for Tower Bolt Solutions

Looking for a reliable Tower Bolt Manufacturer? At JM Hardware®, we are committed to delivering high-quality tower bolts tailored to your project’s specific needs. Whether you require bolts for telecom towers, construction projects, or heavy-duty industrial applications, we have the expertise and capability to provide the perfect solution.

Contact us today to request a quote or learn more about our products and services. JM Hardware® – Your trusted partner for premium fasteners!