-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

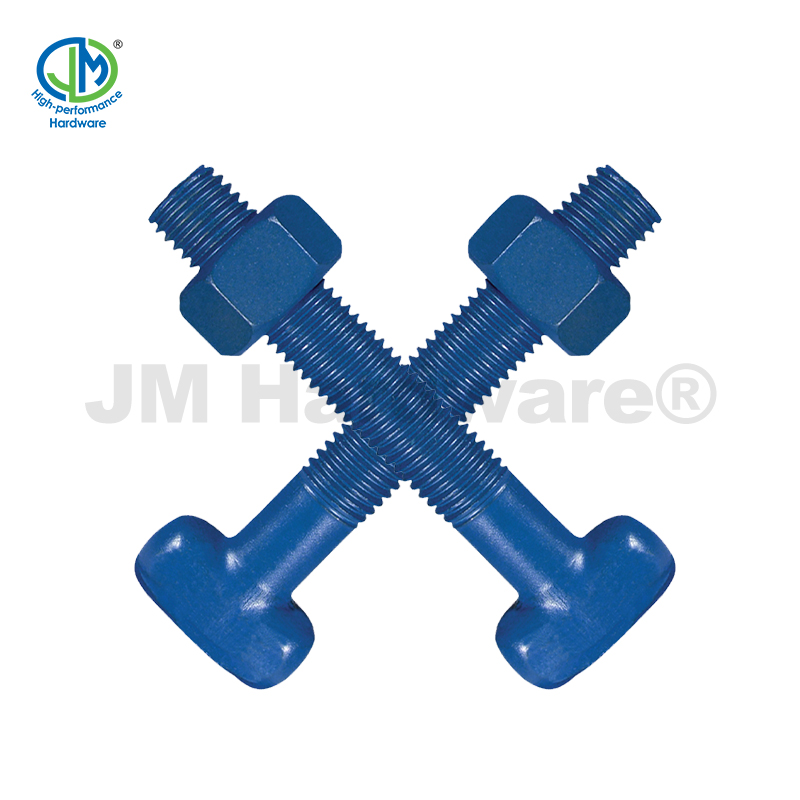

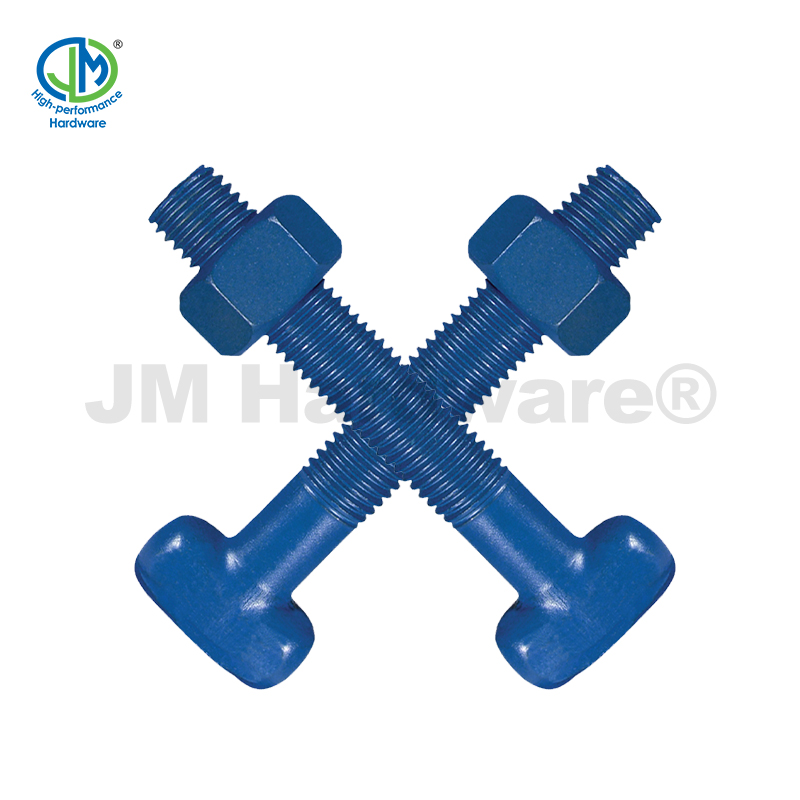

As a trusted T-Bolt Manufacturer, JM Hardware® specializes in producing high-quality T-bolts designed to meet the demanding requirements of industrial, construction, and engineering applications. T-bolts, also known as hammerhead bolts, are essential fastening solutions for applications where secure connections and adjustability are critical. Our extensive manufacturing expertise, premium materials, and advanced processes allow us to deliver T-bolts that offer exceptional durability, precision, and reliability.

Why Choose JM Hardware® as Your T-Bolt Manufacturer?

At JM Hardware®, we understand the diverse needs of industries that rely on T-bolts. Here’s why B2B buyers trust us as their preferred supplier:

1.Custom Manufacturing: We offer tailored T-bolts to meet your specific requirements, including non-standard sizes, unique shapes, and special coatings.

2.Wide Material Options: Our T-bolts are made from premium materials, ensuring long-lasting performance in even the harshest environments.

3.High Volume Capacity: Equipped with advanced production lines, we can handle both small and bulk orders, meeting the needs of large-scale industrial projects.

4.Precision Engineering: With strict quality control, we ensure that every T-bolt is manufactured to precise tolerances, guaranteeing a perfect fit and secure fastening.

5.Global Delivery: With a robust supply chain, we deliver high-quality T-bolts to projects worldwide, on time and within budget.

Comprehensive Product Range

Our T-bolts are designed to suit a variety of applications across industries. We offer:

-

Standard T-Bolts

Manufactured to meet international standards, these bolts are ideal for universal applications.

-

Heavy-Duty T-Bolts

Built to handle high loads and stresses, commonly used in construction and engineering projects.

-

Stainless Steel T-Bolts

Corrosion-resistant bolts for marine, outdoor, and chemical environments.

-

High-Strength Alloy T-Bolts

Designed for applications requiring maximum durability and load capacity.

-

Custom T-Bolts

Tailored to your exact specifications, including special thread designs, head shapes, and surface coatings.

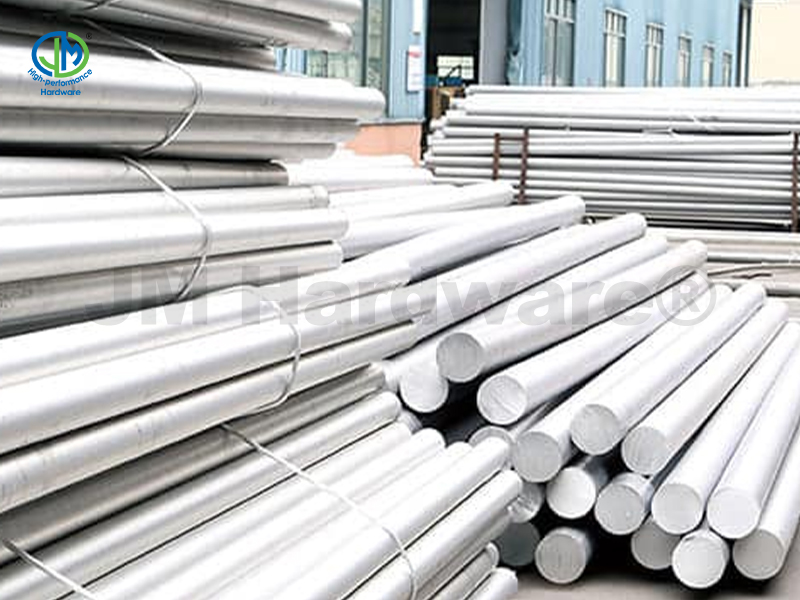

Materials We Use in T-Bolt Manufacturing

To ensure top performance and durability, our T-bolts are crafted from the finest materials, including:

-

Carbon Steel:

Ideal for general-purpose use, offering excellent strength and cost-effectiveness.

-

Stainless Steel (SS304, SS316):

Provides exceptional corrosion resistance, making it perfect for outdoor or marine applications.

-

Alloy Steel:

Offers superior strength and wear resistance, ideal for high-stress and heavy-duty applications.

-

Duplex Stainless Steel:

Combines high strength with excellent corrosion resistance, especially in chloride-rich environments.

-

Brass:

Corrosion-resistant and non-magnetic, suitable for electrical and decorative applications.

-

Titanium:

Ultra-strong and lightweight, perfect for aerospace and high-performance projects.

-

Aluminum:

Lightweight and corrosion-resistant, commonly used in transportation and assembly applications.

Surface Finishes for Enhanced Performance

Our T-bolts are available with various surface treatments to enhance durability, corrosion resistance, and overall appearance:

-

Zinc Plating:

Offers moderate corrosion resistance for indoor and light-duty applications.

-

Hot-Dip Galvanizing:

Provides long-lasting protection against rust, ideal for outdoor and marine environments.

-

Teflon Coating:

Excellent resistance to chemicals and friction, suitable for industrial environments.

-

Passivation:

Enhances the natural corrosion resistance of stainless steel bolts.

-

Black Oxide Coating:

Aesthetic and protective, commonly used in machinery and automotive applications.

-

Powder Coating:

Provides a durable, attractive finish for visible installations.

-

Phosphate Coating:

Reduces friction and improves corrosion resistance for threaded components.

Applications of Swing Bolts

T-bolts are versatile fasteners used in a wide range of industries and applications. Some of the most common uses include:

-

Automotive

Essential in assembling engine components, suspensions, and mounting systems.

-

Heavy Machinery

T-bolts provide secure connections for large equipment and industrial machines.

-

Marine Engineering

Perfect for securing and aligning components in shipbuilding, docks, and offshore platforms.

-

Agriculture Equipment

Fastening components of tractors, harvesters, and other machinery.

-

Oil & Gas

With corrosion-resistant finishes, T-bolts are used in pipelines, flanges, and offshore structures.

-

Solar Power Installations

Securing solar panel mounting systems for reliable and long-lasting performance.

-

Construction

T-bolts are used in securing framework, scaffolding, and steel structures.

-

HVAC Systems

Securing ducts, pipes, and other components in heating, ventilation, and air conditioning systems.

-

Electrical and Utility Poles

Used in assembling utility poles and telecom towers.

-

Furniture and Assembly Lines

Ideal for modular furniture and automated production lines.

Standards for T-Bolts

Our T-bolts are manufactured to meet the most stringent international standards, ensuring quality and reliability:

-

DIN (Deutsches Institut für Normung)

-

ASTM (American Society for Testing and Materials)

-

ISO (International Organization for Standardization)

-

BS (British Standards)

-

JIS (Japanese Industrial Standards)

-

SAE (Society of Automotive Engineers)

Testing and Quality Assurance

At JM Hardware®, quality is at the core of everything we do. As a professional T-bolt manufacturer, we implement rigorous testing procedures to ensure that every bolt meets customer requirements:

-

Tensile Strength Testing:

Verifies the bolt’s ability to withstand applied forces without failure.

-

Corrosion Resistance Testing:

Ensures the fasteners perform reliably in harsh environments.

-

Fatigue Testing:

Confirms the bolt’s durability under repetitive stress.

-

Dimensional Inspection:

Guarantees precision in thread size, length, and tolerances for seamless assembly.

-

Vibration Testing:

Ensures that the bolt maintains its integrity under continuous vibration.

-

Hardness Testing:

Ensures the material meets the required hardness levels for durability.

-

Salt Spray Testing:

Confirms the effectiveness of anti-corrosion coatings.

Our T-Bolt Manufacturing Process

Our advanced manufacturing facilities allow us to produce high-quality T-bolts with efficiency and precision:

-

Material Preparation:

High-quality raw materials are carefully selected for durability and performance.

-

Forging

T-bolt heads are hot or cold forged to achieve strength and precision.

-

Thread Rolling:

Threads are rolled, not cut, to enhance strength and durability.

-

Heat Treatment:

Ensures optimal hardness and toughness for demanding applications.

-

Surface Coating:

Coatings and finishes are applied to enhance corrosion resistance and overall performance.

-

Quality Control:

Each bolt is inspected and tested to ensure compliance with customer specifications and industry standards.

Why JM Hardware® is the Trusted T-Bolt Manufacturer for B2B Buyers

1.Wide Product Range: From standard to custom T-bolts, we meet every industry need.

2.Custom Solutions: We manufacture non-standard bolts to your exact specifications.

3.Competitive Pricing: Efficient production processes allow us to offer premium products at competitive prices.

4.Global Supply: Reliable and timely delivery, no matter where your project is located.

5.Industry Expertise: Decades of experience providing fasteners for large-scale industrial projects.

6.High Quality: Rigorous testing ensures that every bolt meets the highest standards.

Contact JM Hardware® – Your Reliable T-Bolt Manufacturer

Whether you need standard T-bolts or custom fasteners for specialized applications, JM Hardware® is your trusted partner for high-quality solutions. Contact us today to discuss your project requirements or request a quote. With JM Hardware®, you’ll receive durable, reliable, and precision-engineered T-bolts for your industrial needs. Let us power your projects with fasteners you can depend on!