-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

JM Hardware® is dedicated to crafting superior stud bolts that cater to the rigorous demands of construction, oil & gas, and various industrial sectors. Our extensive selection of stud bolts comes in a variety of materials, coatings, grades, and standards, ensuring suitability for a multitude of projects and environmental conditions. We are pleased to present a comprehensive review of our stud bolt range, covering their different designations, materials, surface treatments, grades, standards, applications, testing methods, and production processes.

Designations of Stud Bolts

Stud bolts, often referred to by various names such as double-ended bolts, fully-threaded rods, threaded rods, studs, and anchor bolts in specific uses, are recognized for their dual-threaded ends and are commonly paired with nuts for securing flanged connections and other components.

Materials for Stud Bolt Manufacturing

At JM Hardware®, we pride ourselves on offering stud bolts in an array of materials to guarantee optimal performance across different settings:

● Carbon Steel: A cost-effective choice for general applications, providing adequate strength.

● Stainless Steel (SS304, SS316, SS316L, etc.): Offers corrosion resistance, making it ideal for marine and chemical processing applications.

● Alloy Steel: Delivers exceptional strength and durability for high-stress environments like power plants and the oil & gas industry.

● Nickel-Based Alloys (Inconel, Monel, Hastelloy): Engineered to endure extreme temperatures and corrosive conditions.

● Duplex and Super Duplex Stainless Steel: Combines high strength with outstanding corrosion resistance, particularly in chloride-rich environments.

-

Carbon Steel

-

Stainless Steel

-

Alloy Steel

-

Duplex and Super Duplex Stainless Steel

-

Hastelloy

-

Inconel, Monel

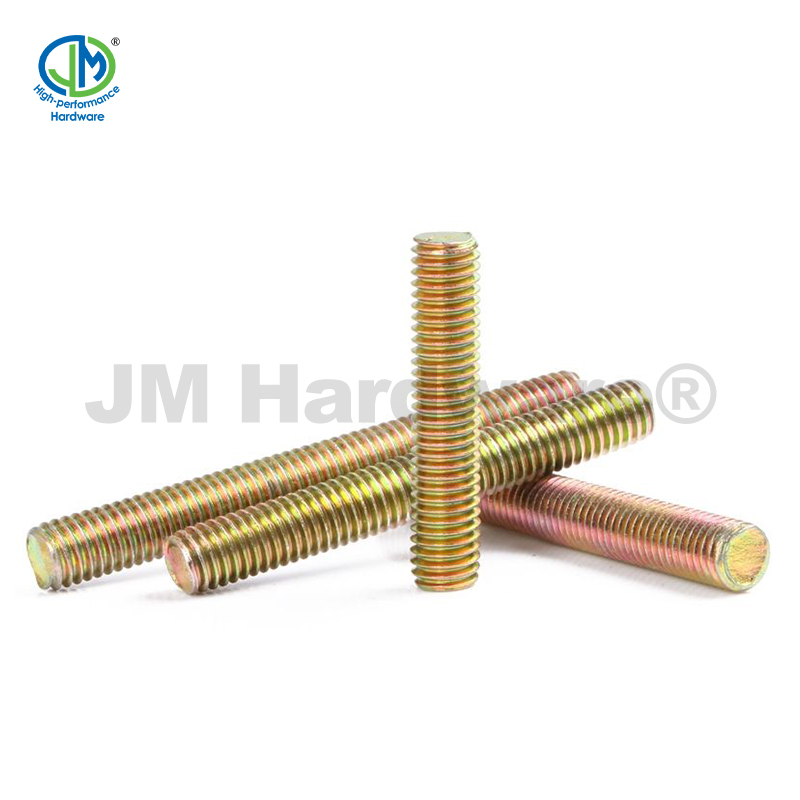

Surface Treatments

We provide a selection of surface treatments to enhance the longevity and corrosion resistance of stud bolts:

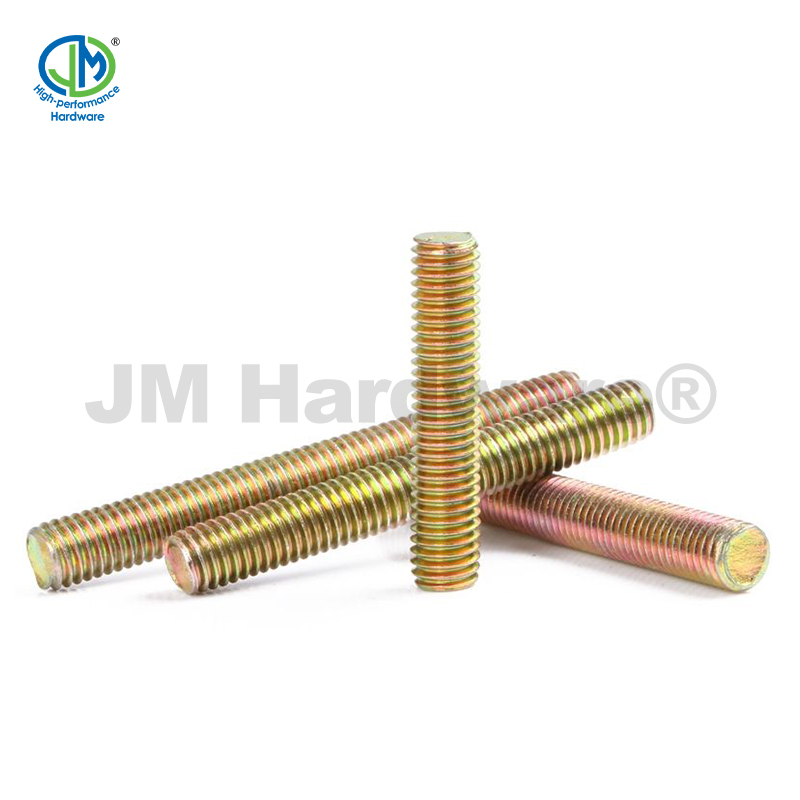

● Zinc Plating: Offers moderate corrosion resistance, suitable for indoor applications.

● Hot-Dip Galvanizing: Provides superior corrosion protection, ideal for outdoor and marine settings.

● Black Oxide: Delivers a sleek finish with minimal corrosion resistance, fitting for indoor or low-humidity conditions.

● Teflon (PTFE) Coating: Offers chemical resistance and excellent corrosion protection, especially in the oil & gas sector.

● Dacromet Coating: An advanced coating for superior corrosion resistance and environmental friendliness.

● Cadmium Plating: Offers good lubricity and corrosion resistance, commonly used in aerospace applications.

-

Black Oxide

-

Dacromet Coating

-

Hot-Dip Galvanizing

-

Teflon (PTFE) Coating

-

Yellow zinc plated

-

Zinc Plating

Grades of Stud Bolts

Our stud bolts are available in various grades, indicating their strength and mechanical properties:

● Grade 4.8, 8.8, 10.9, 12.9 (Carbon Steel)

● ASTM A193 Grade B7, B7M, B16 (Alloy Steel)

● ASTM A320 Grade L7, L7M (Low-temperature service)

● ASTM A194 Grade 2H, 2HM, 7, 7M, 8, 8M (Nuts paired with stud bolts)

● ASTM A193 Grade B8, B8M (Stainless Steel)

● ASTM A325 and A490 (Structural applications)

Each grade is tailored for specific temperature, pressure, and environmental conditions.

-

ASTM A193 Grade B7, B7M, B16

-

ASTM A193 Grade B8, B8M

-

ASTM A194 Grade 2H, 2HM, 7, 7M, 8, 8M

-

ASTM A320 Grade L7, L7M

-

ASTM A325 and A490

-

Duplex Stainless Steel

-

Grade 4.8, 8.8, 10.9, 12.9

-

Inconel, Monel, Hastelloy

Standards for Stud Bolts

Our stud bolts adhere to a broad spectrum of international standards, ensuring top-tier quality and safety:

-

ANSI

-

ASTM

-

BS

-

DIN

-

EN

-

ISO

These standards define the dimensional, mechanical, and material properties of stud bolts, ensuring consistency and reliability across projects.

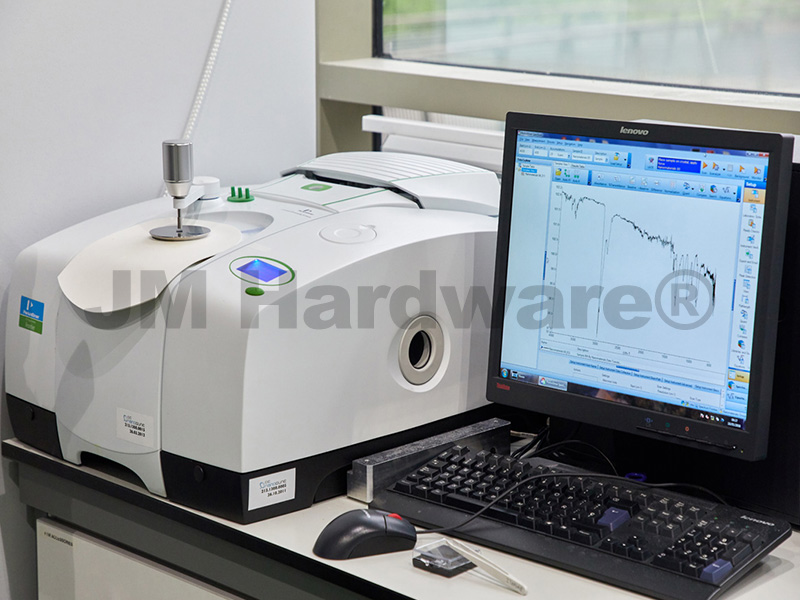

Testing Methods for Stud Bolts

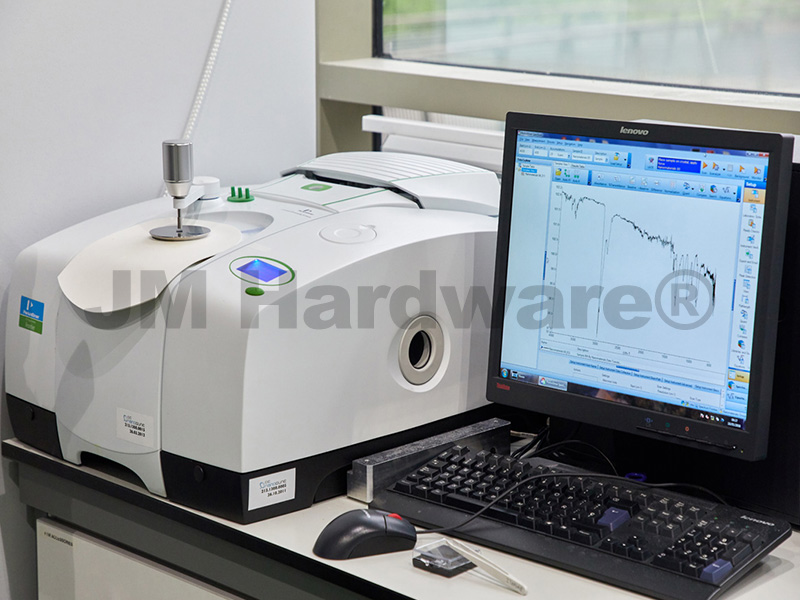

At JM Hardware®, we uphold stringent quality control measures to ensure our stud bolts meet the necessary standards for strength, durability, and corrosion resistance:

-

Tensile Strength Testing

-

Hardness Testing

-

Corrosion Resistance Testing (e.g., ASTM B117 salt spray tests)

-

Dimensional Inspection

-

Non-Destructive Testing (NDT) (e.g., ultrasonic testing or radiography)

-

Hydrogen Embrittlement Testing

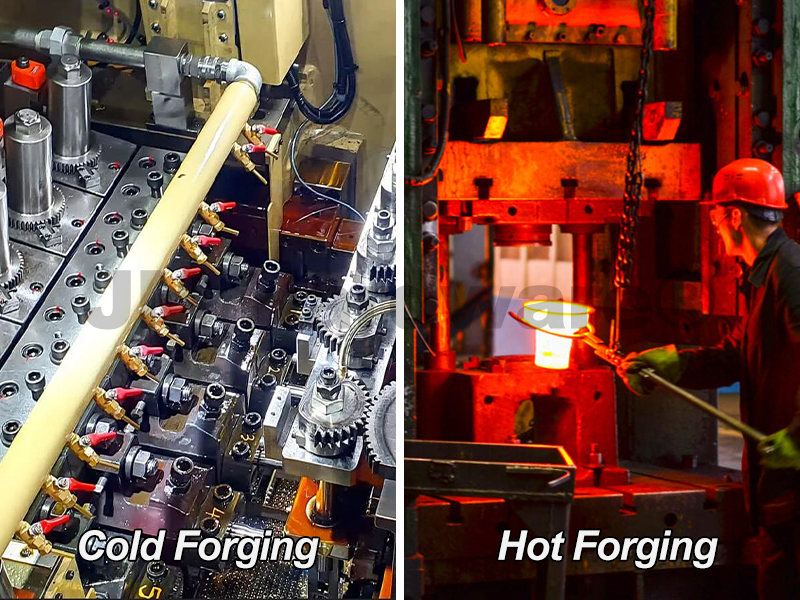

Production Processes of Stud Bolts

Our advanced manufacturing processes guarantee the highest quality stud bolts:

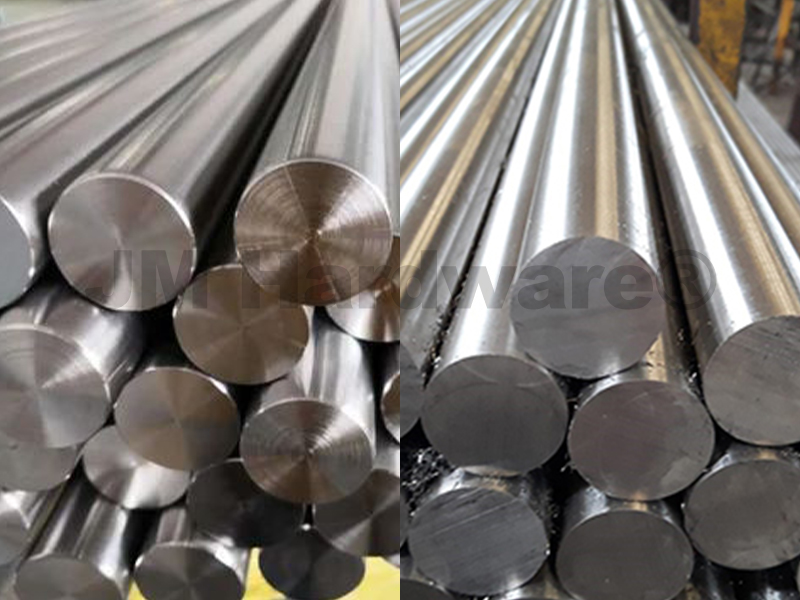

1.Raw Material Selection: We start with the right materials for your specific application.

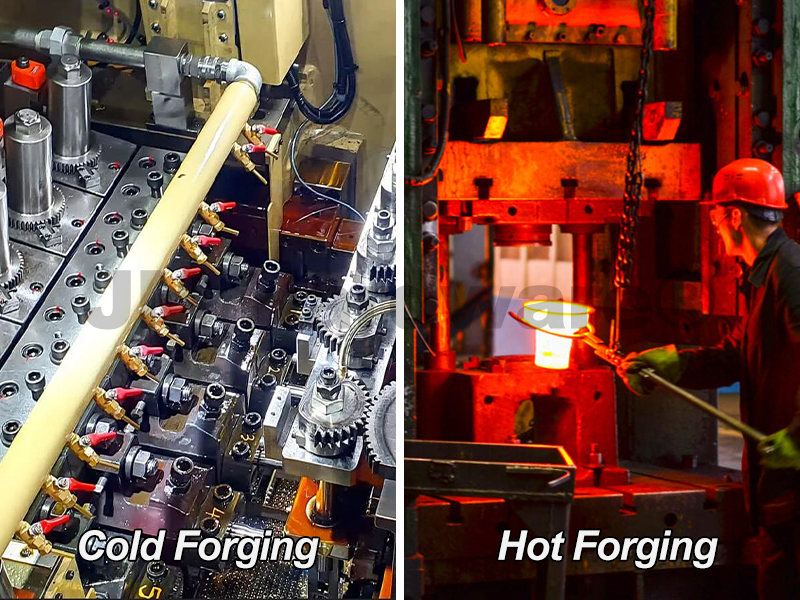

2.Cold Forging or Hot Forging: Depending on the material and strength requirements.

3.Thread Rolling: Enhances bolt strength by compressing the material.

4.Heat Treatment: Achieves desired hardness and mechanical properties.

5.Surface Treatment: Applies various coatings as per customer requirements.

6.Quality Control: Rigorous inspection and testing before packaging and shipping.

-

Raw Material Selection

-

Cold Forging or Hot Forging

-

Thread Rolling

-

Heat Treatment

-

Surface Treatment

-

Quality Control

Why Choose JM Hardware® for Your Stud Bolt Needs?

● Premium Materials: Ensuring durability and performance in demanding applications.

● Extensive Product Range: Offering a wide selection of materials and coatings.

● Customization: Producing custom stud bolts to meet unique project requirements.

● Industry Expertise: Years of experience in manufacturing stud bolts for various industries.

● In-Stock and Ready to Ship: Maintaining a large inventory to meet immediate needs.

● Competitive Pricing: Offering high-quality products at competitive prices.

JM Hardware® at the Dubai Hardware Exhibition: Expanding Global Presence

Our participation in the Dubai Hardware Exhibition underscores our commitment to building strong relationships with global customers, staying current with industry trends, and continuously improving our product offerings. This event provided us with an opportunity to showcase our comprehensive range of fasteners and custom solutions, connect with clients and professionals worldwide, and reinforce our position as a reliable and innovative fastener manufacturer.

As we continue to grow, our focus remains on delivering superior fastener solutions globally. Whether you need standard or customized fasteners, JM Hardware® is here to meet your project needs with in-stock products, fast delivery, and competitive pricing. We thank all attendees and potential partners in Dubai and look forward to building strong, lasting relationships, supplying high-quality fasteners for projects worldwide.

Applications and Usage Scenarios

Stud bolts are indispensable in numerous industries due to their versatility, strength, and reliability:

● Oil & Gas Industry: Utilized in flanged connections, pressure vessels, and pipelines.

● Petrochemical Industry: Resists harsh chemicals and extreme temperatures in reactors and refineries.

● Construction Industry: Anchor bolts and threaded rods are prevalent in concrete and steel structures.

● Power Plants: Secures turbines, boilers, and pressure vessels.

● Marine & Offshore Applications: Stainless steel and corrosion-resistant alloys are vital for saltwater environments.

● Aerospace & Defense: Specialty alloy stud bolts are employed in high-stress, high-temperature environments like jet engines.

-

Aerospace & Defense

-

Construction

-

Marine & Offshore Applications

-

Oil & Gas Industry

-

Petrochemical

-

Power Plants