-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing step bolts, offering durable and precision-engineered fasteners for a variety of industrial and commercial applications. As a trusted step bolt manufacturer, we deliver premium-quality products that meet international standards, ensuring safety, reliability, and performance in every project. From structural towers to industrial machinery, our step bolts are designed to provide long-lasting solutions for your fastening needs.

What Are Step Bolts?

Step bolts, often referred to as safety bolts, are specialized fasteners with a large, flat, smooth head and a long shank. These bolts are primarily used in applications where climbing is required, such as utility poles, communication towers, and industrial structures. Their flat, domed heads offer safety and comfort when used as climbing steps, and their robust construction ensures high strength and stability.

Why Choose JM Hardware® as Your Step Bolt Manufacturer?

1.Extensive Experience: With over 18 years of expertise in fastener manufacturing, JM Hardware® is a trusted partner for industries worldwide.

2.Custom Solutions: We manufacture step bolts to your exact specifications, including dimensions, materials, and finishes.

3.Strict Quality Control: Every bolt undergoes rigorous testing to ensure it meets international standards and project-specific requirements.

4.Global Supply Network: We provide timely delivery and reliable service to clients across the globe.

5.Competitive Pricing: Our efficient production processes enable us to offer top-quality products at highly competitive prices.

Applications of Step Bolts

Step bolts are critical in various industries, offering both functional and safety benefits. Common applications include:

-

Utility Poles

Used as climbing steps for maintenance personnel.

-

Telecommunication Towers

Provide secure footing for technicians accessing antennas and other equipment.

-

Wind Turbines

Enable safe climbing and maintenance of turbine towers.

-

Industrial Structures

Used as steps or fasteners in steel frameworks and equipment installations.

-

Storage Tanks and Silos

Allow easy access for inspection and cleaning.

-

Streetlights and High-Mast Poles

Facilitate secure access for electrical repairs and installations.

-

Construction Projects

Provide climbing support in scaffolding and temporary structures.

Materials Used in Step Bolts

As a leading step bolt manufacturer, we offer a wide range of materials to ensure optimal performance in different environments:

-

Carbon Steel:

Offers high tensile strength and durability, suitable for standard applications.

-

Stainless Steel (SS304, SS316):

Provides superior corrosion resistance, making it ideal for outdoor and marine environments.

-

Alloy Steel:

Known for its excellent strength and fatigue resistance, perfect for high-load applications.

-

Galvanized Steel:

Combines strength and rust resistance, commonly used in outdoor structures like towers and poles.

-

Duplex Stainless Steel:

Offers exceptional strength and chloride-resistant properties, ideal for harsh environments.

-

Brass and Aluminum:

6.Lightweight and corrosion-resistant, used for specific applications like electrical installations.

Surface Finishes for Step Bolts

We provide a variety of surface finishes to enhance the durability, corrosion resistance, and aesthetics of step bolts:

-

Zinc Plating:

Provides a cost-effective layer of corrosion resistance for general-purpose applications.

-

Hot-Dip Galvanizing:

Long-lasting rust protection, perfect for outdoor applications such as utility poles and towers.

-

Teflon Coating:

Provides chemical resistance and reduces friction for specialized installations.

-

Epoxy Coating:

High-performance coating designed for extreme weather and industrial environments.

-

Black Oxide Coating:

Offers a sleek appearance with moderate corrosion resistance, ideal for indoor use.

-

Powder Coating:

Enhances aesthetics and adds an extra layer of protection in corrosive environments.

-

Passivation:

Improves the natural corrosion resistance of stainless steel bolts.

Grades and Standards for Step Bolts

As a professional step bolt manufacturer,we produce step bolts that meet various international standards and grades to ensure safety and reliability in diverse applications:

-

ISO 898

Ensures mechanical properties and dimensional accuracy for global projects.

-

DIN 931, DIN 933, and EN 14399

European standards for high-strength and structural fasteners.

-

ASTM A307, A325, and A490

Commonly used in structural applications like towers and utility poles.

-

Grade 4.8, 8.8, 10.9, and 12.9

These grades are suitable for different load requirements, ranging from light-duty to heavy-duty applications.

-

SAE J429

Designed for automotive and heavy machinery applications.

Step Bolt Testing Methods

At JM Hardware®, we prioritize safety and performance, which is why all our step bolts undergo comprehensive testing, including:

-

Tensile Strength Testing:

Ensures the bolt can withstand the required load without failure.

-

Salt Spray Testing:

Verifies corrosion resistance in harsh environments.

-

Fatigue Testing:

Measures the bolt’s ability to endure repetitive stress cycles over time.

-

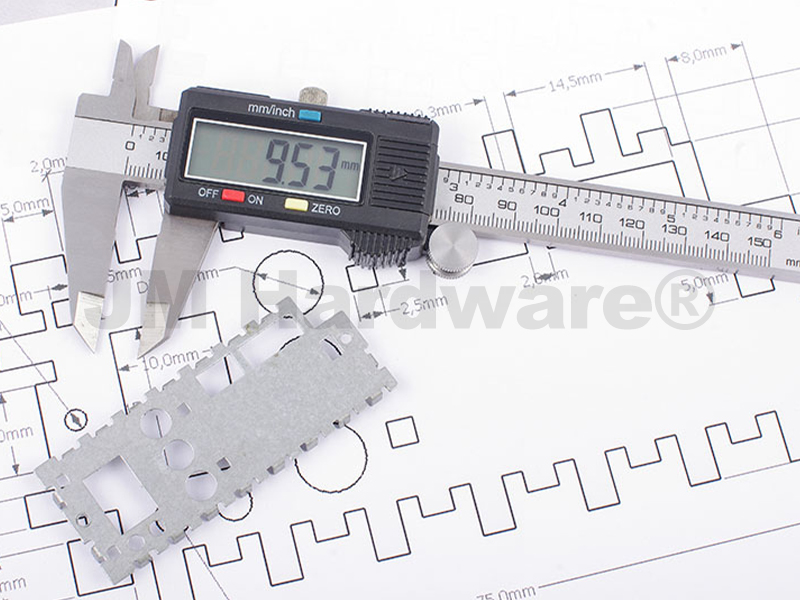

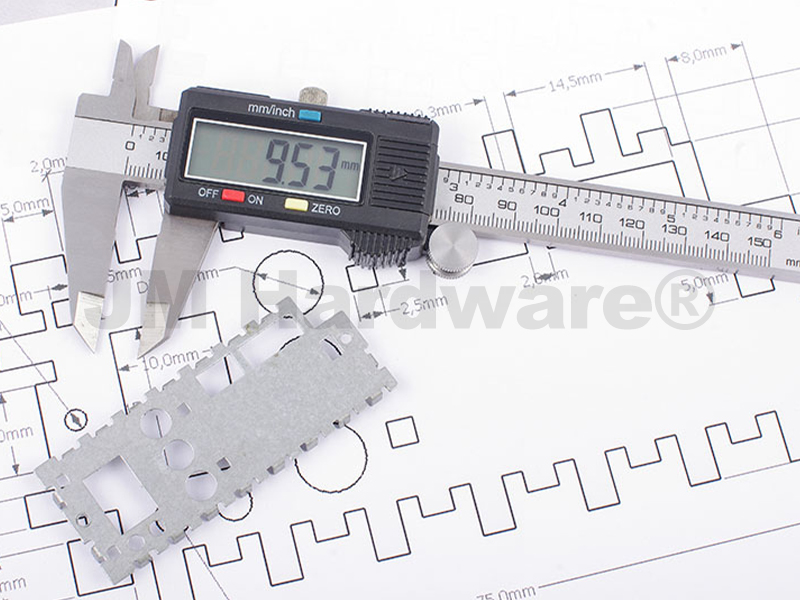

Dimensional Inspection:

Guarantees precise thread and shank dimensions for seamless installation.

-

Impact Testing:

Ensures bolts can handle sudden loads or impacts.

-

Hardness Testing:

Ensures the material meets the required hardness levels for durability.

-

Vibration Testing:

Verifies the bolt’s ability to maintain a secure connection under vibration.

Production Process of Step Bolts

As a leading headed anchor bolt manufacturer, we utilize advanced production processes to deliver consistent, high-quality products:

-

Material Selection:

Premium-grade raw materials are selected based on the intended application.

-

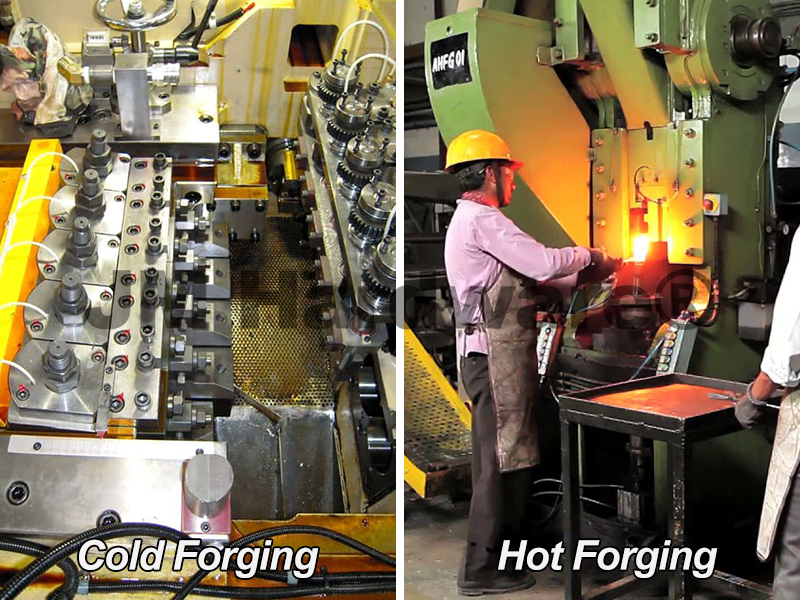

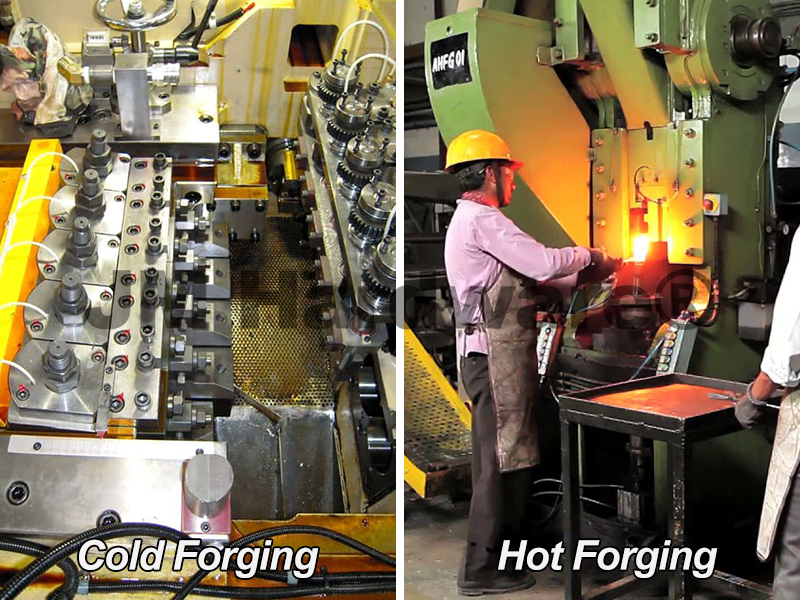

Forging:

Bolts are forged to the desired shape and size, ensuring high strength and durability.

-

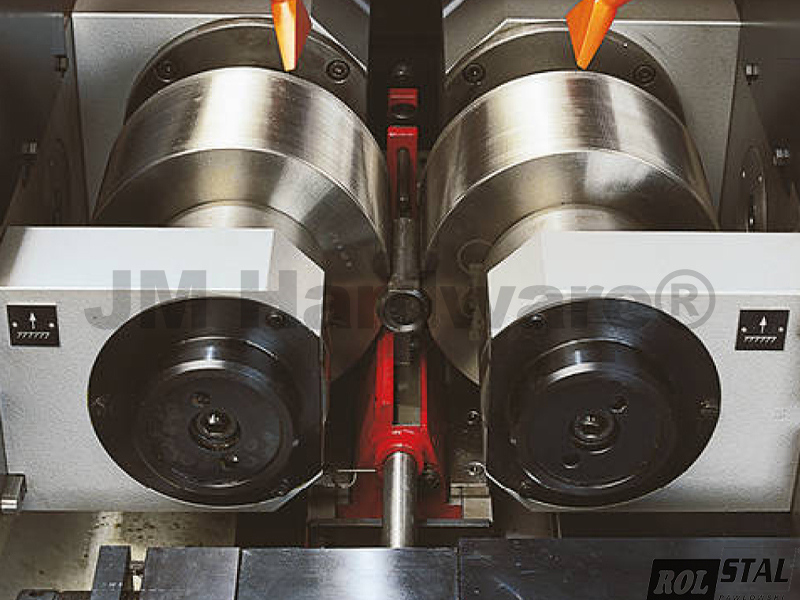

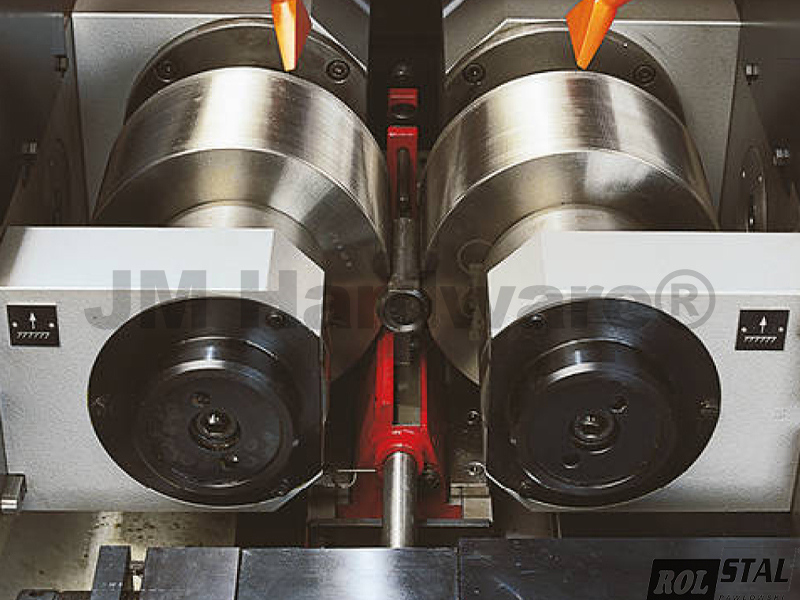

Thread Rolling:

Threads are rolled, not cut, to enhance tensile strength and resistance to wear.

-

Heat Treatment:

Bolts are heat-treated for improved strength and toughness.

-

Surface Coating:

Protective finishes are applied to enhance corrosion resistance and appearance.

-

Quality Inspection:

Each bolt is inspected and tested to ensure compliance with customer specifications and industry standards.

Why JM Hardware® is the Trusted Step Bolt Manufacturer

1.Customized Solutions: We manufacture step bolts in non-standard sizes, materials, and coatings to meet unique project requirements.

2.Extensive Product Range: From standard bolts to specialized fasteners, we cover all your needs.

3.Unmatched Durability: Our step bolts are designed to withstand extreme environmental conditions and heavy loads.

4.Global Shipping: We ensure fast and reliable delivery to projects worldwide.

5.Competitive Pricing: High-quality products at industry-leading prices.

6.Customer Support: Our team is always available to provide expert advice and support.

Contact JM Hardware® for Step bolt Solutions

As a professional step bolt manufacturer, JM Hardware® is your trusted partner for high-quality step bolts tailored to your project needs. Contact us today to learn more about our products, request a quote, or discuss your custom requirements. Trust JM Hardware® for durable, reliable, and precision-engineered fastener solutions!