-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

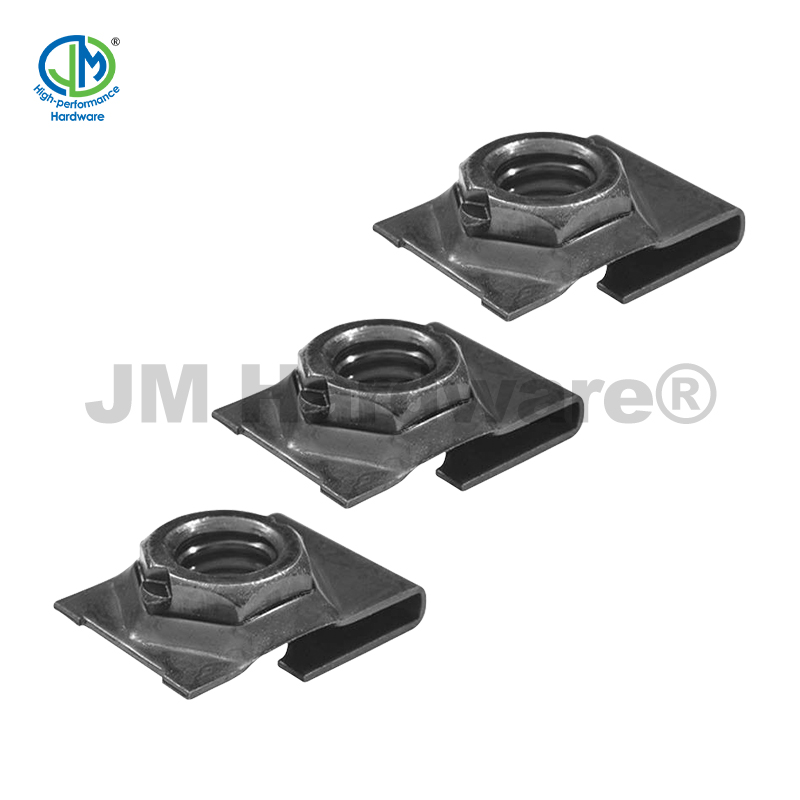

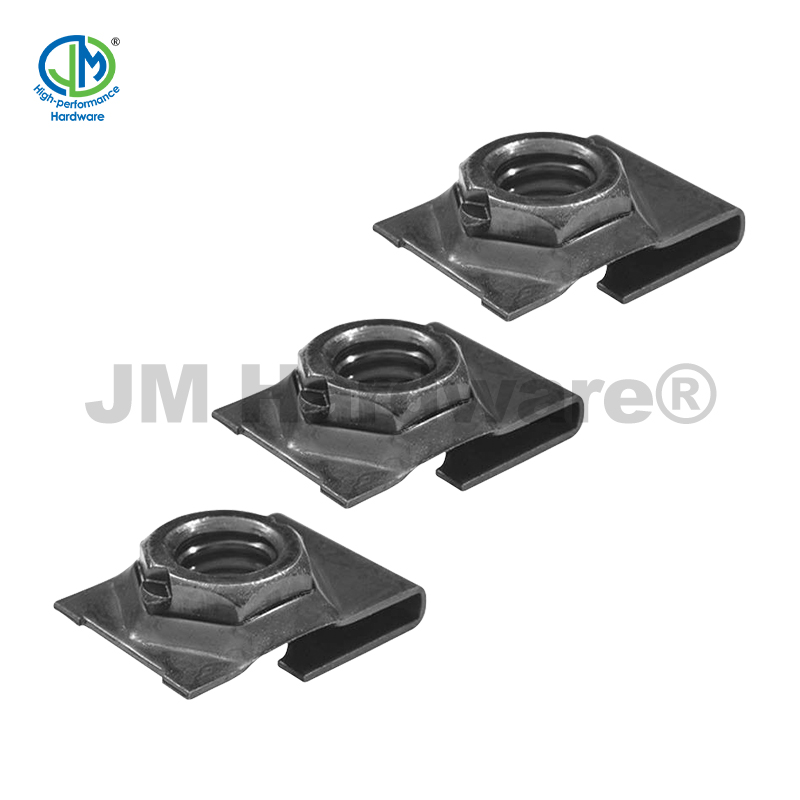

At JM Hardware®, we are a leading Press Nut Manufacturer, specializing in the production of high-quality press nuts for various industries, including automotive, electronics, construction, and machinery. With advanced manufacturing capabilities, custom solutions, and rigorous quality control processes, we deliver press nuts that meet the most demanding requirements for durability, precision, and performance. Below, we provide a detailed overview of our press nut offerings, highlighting their unique features, materials, coatings, grades, standards, applications, and manufacturing processes to help you make informed decisions for your business.

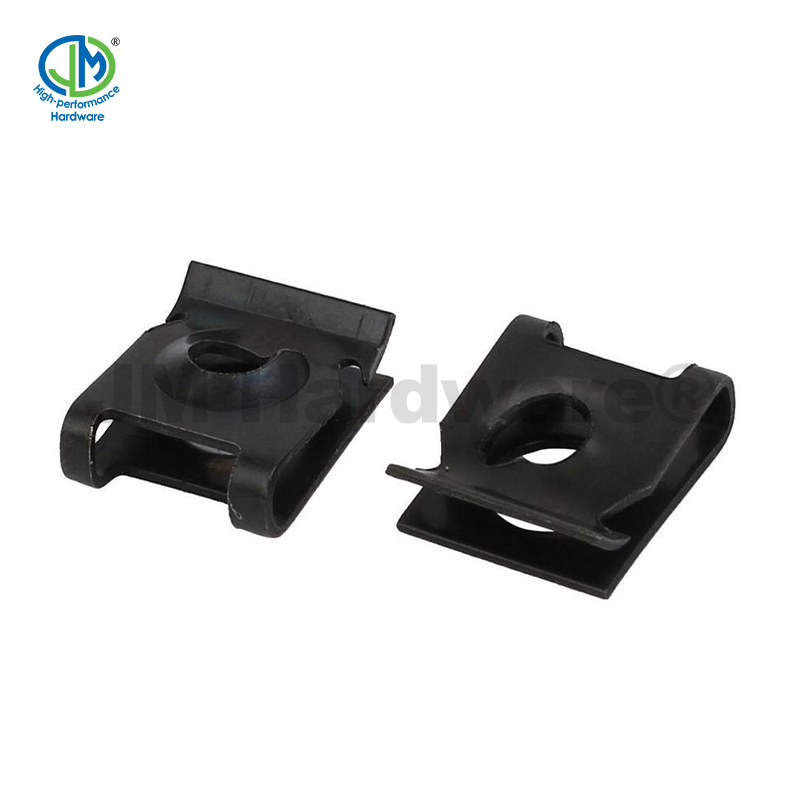

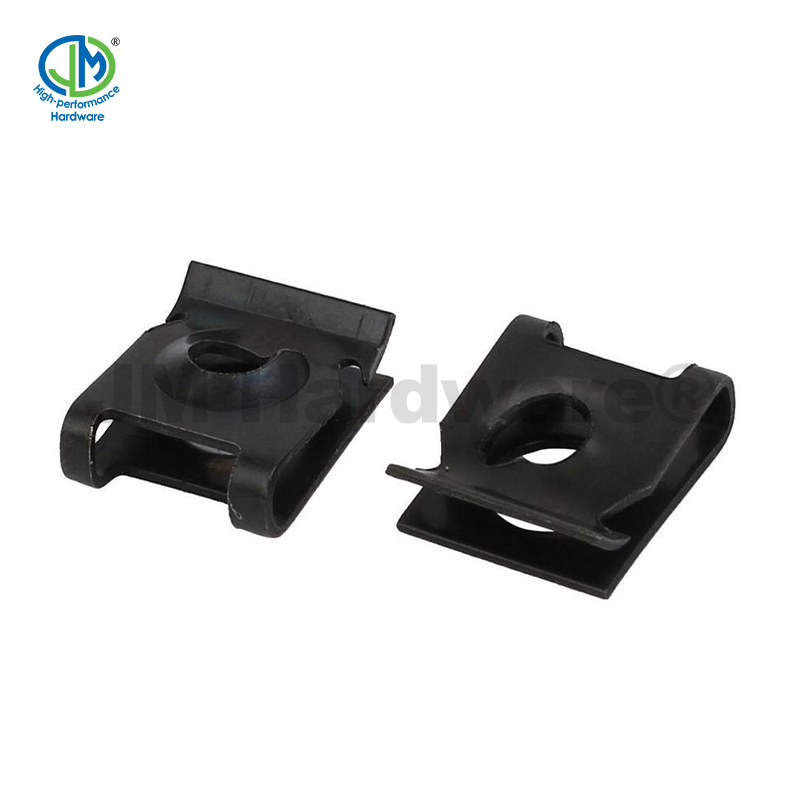

Different Names for Speed Nuts

Speed nuts are known by several names across various industries, including:

-

Push-on nuts

-

Sheet metal nuts

-

Clip nuts

-

Spring nuts

-

U-nuts and J-nuts

(specific designs within the speed nut family)

Speed nuts are characterized by their self-retaining and self-locking capabilities, allowing quick and secure fastening without the need for additional tools.

Materials Used in Speed Nut Manufacturing

We offer speed nuts in a range of materials, ensuring high performance and compatibility with different environments:

-

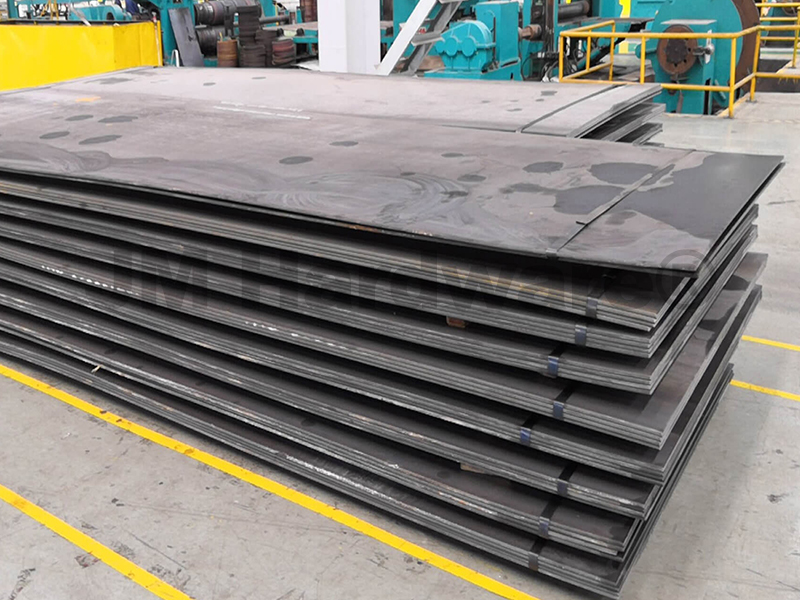

Carbon Steel:

Commonly used for its strength and affordability, suitable for general-purpose applications.

-

Stainless Steel (SS304, SS316):

Known for its excellent corrosion resistance, stainless steel is ideal for outdoor or humid environments where rust could be an issue.

-

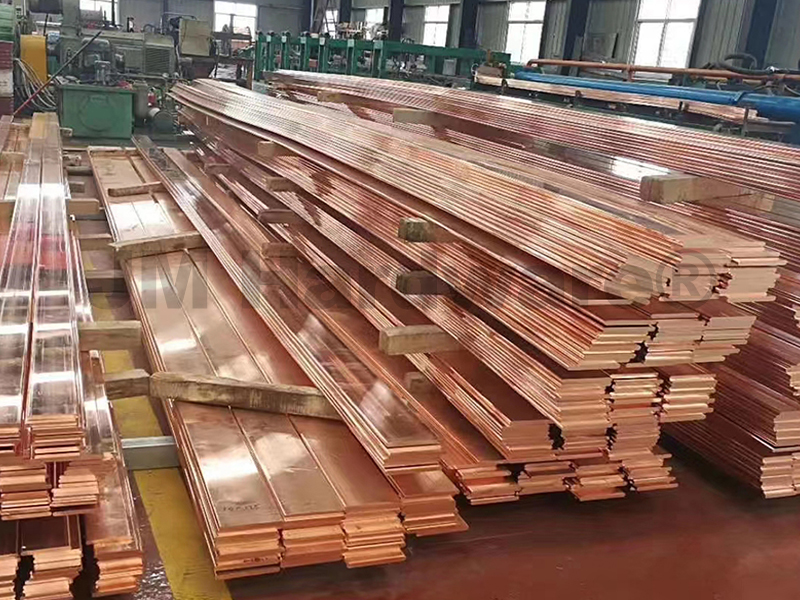

Brass:

Corrosion-resistant and non-magnetic, often used in applications where conductivity or resistance to harsh chemicals is required.

-

Phosphor Bronze:

Offers excellent wear resistance and anti-corrosive properties, making it ideal for electronics and marine applications.

-

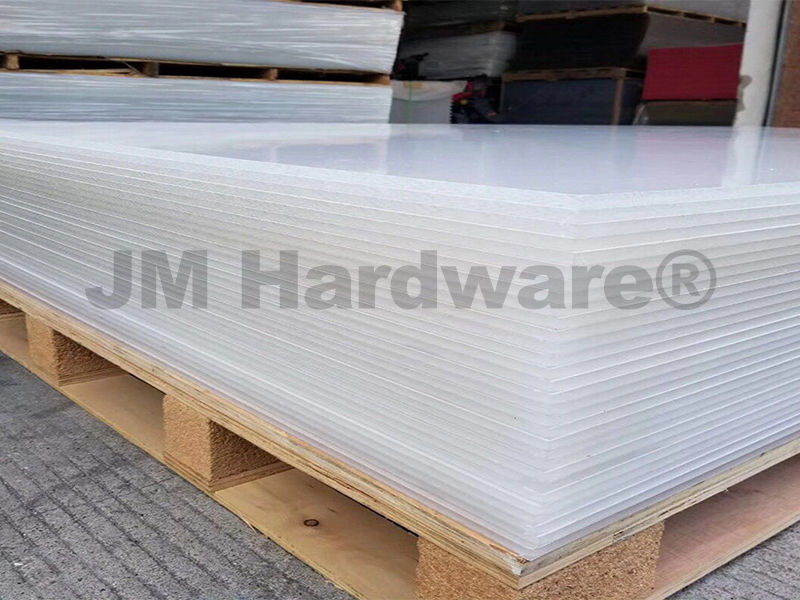

Plastic/Polymer:

Lightweight and resistant to corrosion, used in applications where electrical insulation or reduced weight is a priority.

Surface Treatments for Speed Nuts

We provide various surface treatments to enhance the durability and performance of our speed nuts. These treatments offer protection against corrosion, wear, and environmental factors:

-

Zinc Plating:

Provides good corrosion resistance and is commonly used in indoor environments.

-

Black Oxide:

Offers a sleek black finish with moderate corrosion resistance, suitable for low-humidity environments.

-

Phosphate Coating:

Often used for automotive applications, providing lubrication and corrosion resistance.

-

Nickel Plating:

Adds a shiny finish and increased corrosion resistance, particularly useful for decorative applications.

-

Teflon Coating:

Offers a non-stick surface and chemical resistance, suitable for extreme environments.

-

Passivation(for stainless steel):

Enhances the natural corrosion resistance of stainless steel by removing surface impurities.

Grades of Speed Nuts

While speed nuts do not typically follow the same grading system as bolts and screws, we ensure that our speed nuts meet specific quality grades and standards. For example:

-

Automotive-Grade Speed Nuts:

Built to withstand the high vibrations and varying temperatures of automotive applications.

-

Industrial-Grade Speed Nuts:

Designed for heavy-duty applications, such as in construction and heavy machinery.

-

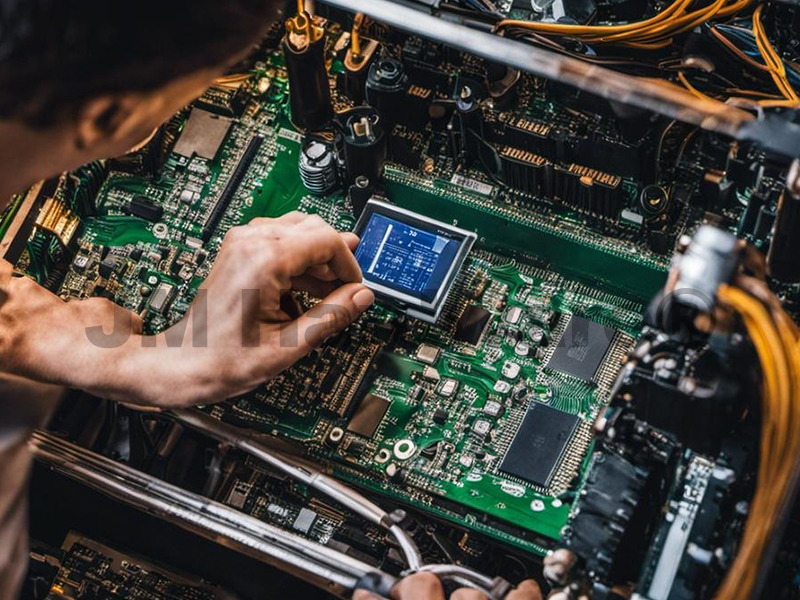

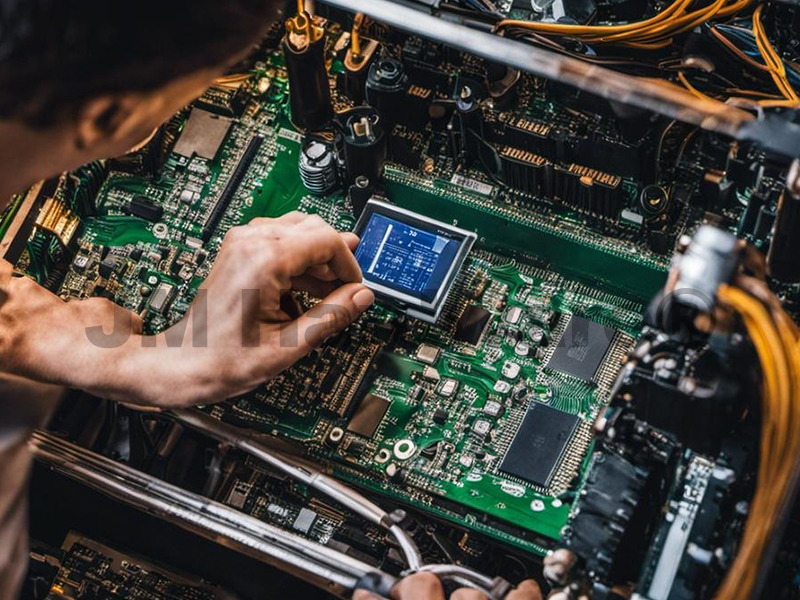

Electronics-Grade Speed Nuts:

Precision-engineered for small-scale, sensitive electronics applications, often with non-magnetic or conductive properties.

Standards for Speed Nuts

Our speed nuts comply with a variety of international standards to ensure uniformity, safety, and reliability across all applications:

-

DIN (Deutsches Institut für Normung):

Sets guidelines for dimensions, tolerances, and materials.

-

ISO (International Organization for Standardization):

Defines international specifications for consistency and quality.

-

SAE (Society of Automotive Engineers):

Common in automotive applications, where high vibration and load-bearing requirements are crucial.

-

JIS (Japanese Industrial Standards):

Specific to Japanese engineering requirements, often seen in electronics and automotive industries.

Applications of Speed Nuts

Speed nuts are versatile fasteners with applications in various industries due to their ease of installation, durability, and secure hold:

-

Automotive Industry:

Speed nuts are frequently used to fasten panels, dashboards, and other components, providing quick assembly in high-vibration environments.

-

Electronics:

Ideal for lightweight, compact assemblies where precise, secure fastening is needed without the bulk of traditional nuts and bolts.

-

Home Appliances:

Speed nuts are used in securing components like control panels, wiring enclosures, and metal casings.

-

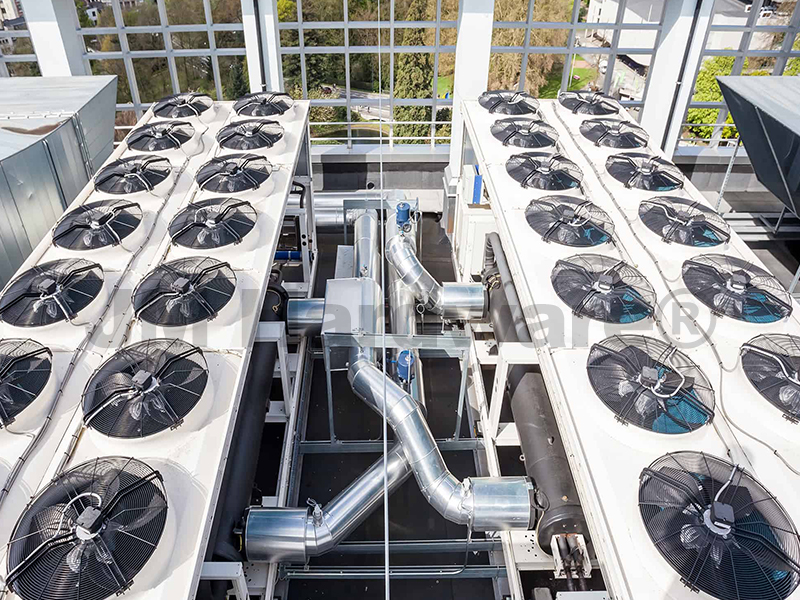

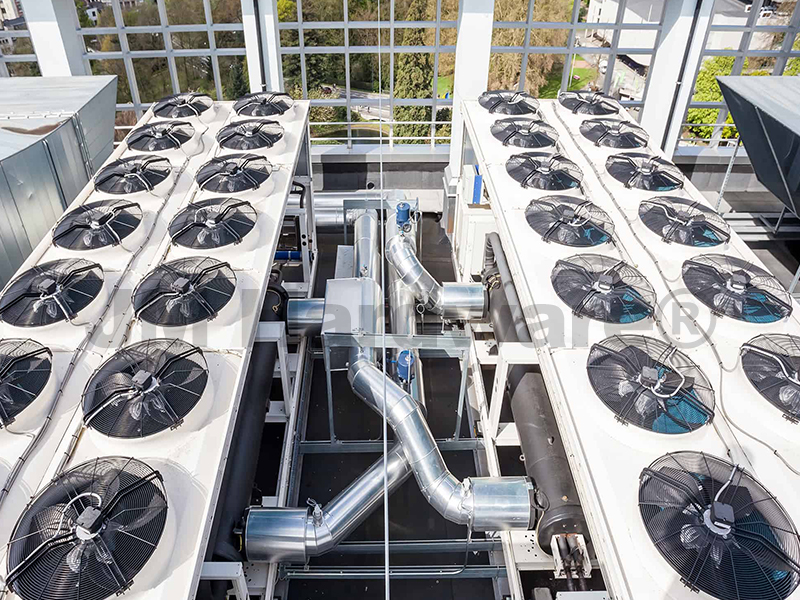

Construction and HVAC:

Used to hold together ductwork, brackets, and metal framing, where quick installation is beneficial.

-

Furniture Assembly:

Provides secure, tool-free fastening for panel assembly in furniture, shelving, and cabinetry.

Testing Methods for Speed Nuts

At JM Hardware®, we follow stringent quality control protocols to ensure that every speed nut meets the required standards for strength, durability, and corrosion resistance. Common testing methods include:

-

Salt Spray Test:

Measures corrosion resistance, particularly for zinc-plated or coated speed nuts.

-

Tensile Strength Testing:

Assesses the nut’s ability to withstand load forces.

-

Dimensional Inspection:

Ensures that the nuts conform to specified dimensional tolerances, which is critical for compatibility with corresponding screws or panels.

-

Hardness Testing:

Verifies that the material meets the required hardness levels for specific applications.

-

Vibration Testing:

Important for automotive and industrial applications, this test ensures that speed nuts do not loosen or lose integrity under high-vibration conditions.

-

Torque Testing:

Evaluates the torque required for installation and removal, ensuring that the speed nut remains secure while still allowing easy installation.

Production Process of Speed Nuts

Our speed nut production process is designed to ensure high quality and consistency across each unit. Key steps include:

-

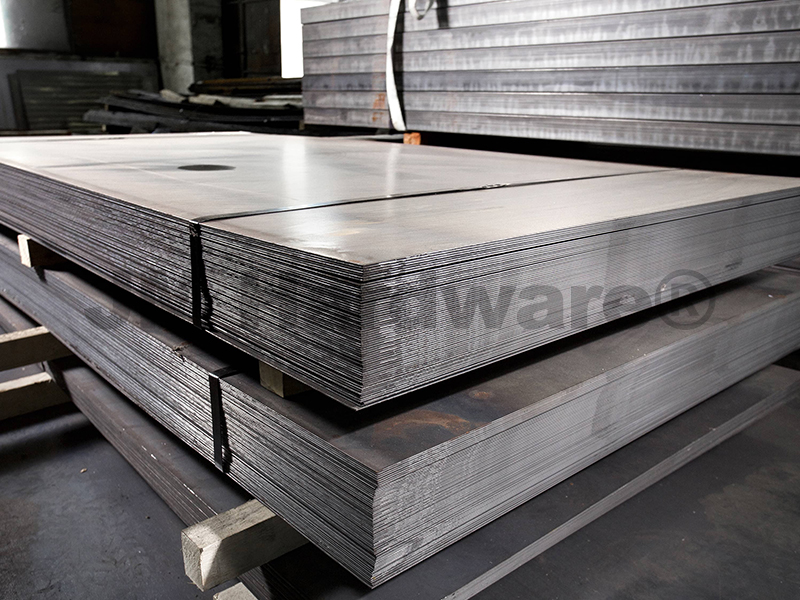

Material Selection:

We start by choosing high-quality raw materials that meet the specific requirements of each application, such as corrosion resistance or strength.

-

Forming Process:

Using precision stamping, we shape each speed nut from sheet metal or other base materials. The forming process includes creating slots, threads, and specific shapes to suit various applications.

-

Heat Treatment(if necessary):

For certain materials, heat treatment is applied to increase strength, hardness, and wear resistance.

-

Surface Treatment:

Depending on the application, we add protective coatings to enhance durability, corrosion resistance, or appearance.

-

Quality Control:

Each batch undergoes rigorous testing and inspection to ensure they meet the required specifications before being packed and shipped.

Why Choose JM Hardware® for Your Speed Nut Needs?

1.High-Quality Materials: We use only premium-grade materials to ensure durability and performance, even in the most demanding applications.

2.Wide Range of Products: From carbon steelto specialty alloys and non-metallic options, we offer an extensive selection to meet various project needs.

3.Customization Options: Need a specific size, material, or finish? We can customize speed nutsto fit your unique project specifications.

4.Industry Expertise: With years of experience in fastener manufacturing, JM Hardware®is trusted across industries like automotive, construction, and electronics.

5.In-Stock and Ready to Ship: We maintain a large inventory of speed nutsin multiple sizes and finishes, ensuring fast delivery to meet tight project timelines.

6.Competitive Pricing: Our efficient manufacturing process allows us to offer high-quality products at competitive prices without compromising on quality.

Our speed nuts are designed to provide quick, reliable fastening solutions for a wide range of applications. For more information on our product offerings, or to request a custom solution, contact us today. At JM Hardware®, we’re dedicated to providing the best fastener solutions for your projects, with speed nuts that meet your exacting standards.