-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we specialize in manufacturing hex flange bolts that deliver exceptional performance across a wide range of industries. Designed with an integrated washer-like flange, these bolts offer greater load distribution, vibration resistance, and secure fastening, making them ideal for demanding applications in construction, automotive, heavy machinery, and more. With our advanced manufacturing capabilities and commitment to quality, JM Hardware® has earned its reputation as a trusted hex flange bolt manufacturer for B2B clients worldwide.

What Are Hex Flange Bolts?

Hex flange bolts are hexagonal head bolts with a built-in flange under the head that acts like a washer. This unique design offers superior load-bearing capacity, prevents loosening due to vibrations, and eliminates the need for a separate washer. They are commonly used in applications requiring secure, reliable fastening with added vibration resistance and simplified installation.

Advantages of Hex Flange Bolts

-

Increased Load Distribution

The flange distributes pressure evenly, reducing the risk of damage to the fastened materials.

-

Enhanced Vibration Resistance

Ideal for high-vibration environments such as automotive engines, heavy machinery, and industrial equipment.

-

Simplified Installation

Eliminates the need for separate washers, reducing assembly time and costs.

-

Secure Fastening

Prevents loosening due to torque and load during use.

-

Versatility

Suitable for a wide range of applications, including structural connections, automotive assemblies, and industrial machinery.

Materials in Hex Flange Bolt Manufacturing

As a leading hex flange bolt manufacturer, JM Hardware® provides bolts made from high-quality materials to meet the specific requirements of various industries. Common materials include:

-

Carbon Steel:

Widely used for general construction, offering excellent tensile strength and cost-effectiveness.

-

Stainless Steel (SS304, SS316):

Provides superior corrosion resistance, making it ideal for marine, chemical, and outdoor applications.

-

Alloy Steel:

Perfect for high-load scenarios due to its exceptional strength and durability.

-

Titanium:

Lightweight and corrosion-resistant, used in aerospace, medical, and high-performance industries.

-

Galvanized Steel:

Coated for enhanced rust resistance, suitable for outdoor or exposed environments.

-

Duplex Stainless Steel:

Combines high strength and excellent corrosion resistance, ideal for extreme environments.

-

Brass:

Offers excellent corrosion resistance and conductivity, often used in electrical applications.

Surface Finishes for Enhanced Durability

Surface treatments are critical for improving the durability and performance of hex flange bolts. At JM Hardware®, we offer a range of finishes to meet the demands of your specific application:

-

Zinc Plating:

Cost-effective rust protection for indoor or low-exposure environments.

-

Hot-Dip Galvanizing:

Provides exceptional corrosion resistance, especially for outdoor and marine projects.

-

Teflon Coating:

Chemical-resistant and ideal for industrial environments.

-

Nickel Plating:

Adds a polished finish with enhanced corrosion resistance, suitable for decorative or high-visibility applications.

-

Black Oxide Coating:

A sleek finish with basic rust protection, often used in machinery and industrial settings.

-

Phosphate Coating:

Reduces friction during installation and offers basic corrosion resistance.

-

Powder Coating:

Adds an extra layer of durability and aesthetics, suitable for specialty applications.

Applications of Hex Flange Bolts

Hex flange bolts are used in a wide range of industries and applications due to their strength, durability, and design advantages:

-

Automotive Industry

Engine components, suspension systems, and chassis connections.

-

Construction

Securing steel beams, columns, and structural frames.

-

Heavy Machinery

Fastening critical parts of industrial equipment.

-

Renewable Energy

Used in wind turbines, solar panel installations, and hydropower equipment.

-

Oil & Gas Industry

High-strength bolts for pipelines, pressure vessels, and offshore platforms.

-

Railway and Infrastructure

Fastening components in bridges, tracks, and signaling systems.

-

Marine Applications

Corrosion-resistant bolts for shipbuilding and offshore installations.

-

Electrical and Utility

8. Securing transmission towers and electrical equipment.

Standards and Grades for Hex Flange Bolts

Our hex flange bolts comply with various international standards to ensure quality and reliability:

-

ISO 4017 / ISO 4161

Dimensions and tolerances for hex flange bolts.

-

DIN 6921

Common European standard for hex flange bolts.

-

ASTM A193 and A194

Standards for high-temperature and high-pressure applications.

-

SAE J429

Automotive industry standards for mechanical properties.

-

JIS B1189

Japanese standards for flange bolts.

-

BS EN 14399

Structural bolting standards in the UK and Europe.

Quality Assurance and Testing

As a professional hex flange bolt manufacturer, JM Hardware® employs strict quality control measures to ensure product reliability. Our testing methods include:

-

Tensile Testing:

Ensures bolts can handle high loads and stress.

-

Torque Testing

Ensures proper tightening without risk of failure or loosening.

-

Corrosion Resistance Testing:

Ensures surface finishes can withstand environmental exposure.

-

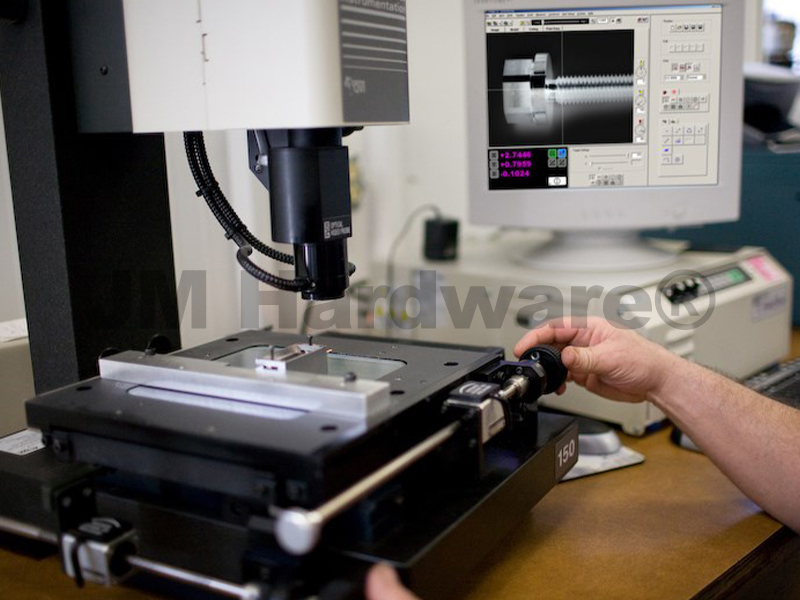

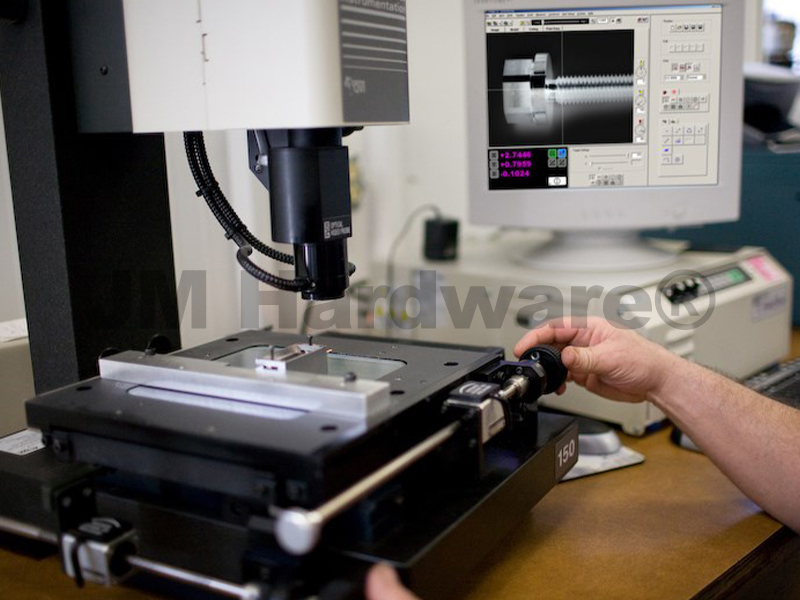

Dimensional Accuracy Testing:

Confirms precise manufacturing tolerances for threads, heads, and flanges.

-

Impact Resistance Testing:

Evaluates performance under repeated loads and shocks.

-

Hardness Testing:

Ensures material hardness meets industry standards.

-

Salt Spray Testing:

Measures resistance to rust in harsh environments.

Manufacturing Process for Headed Anchor Bolts

As a leading headed anchor bolt manufacturer, we utilize advanced production processes to deliver consistent, high-quality products:

-

Raw Material Selection:

Premium materials are sourced to meet strength and corrosion resistance requirements.

-

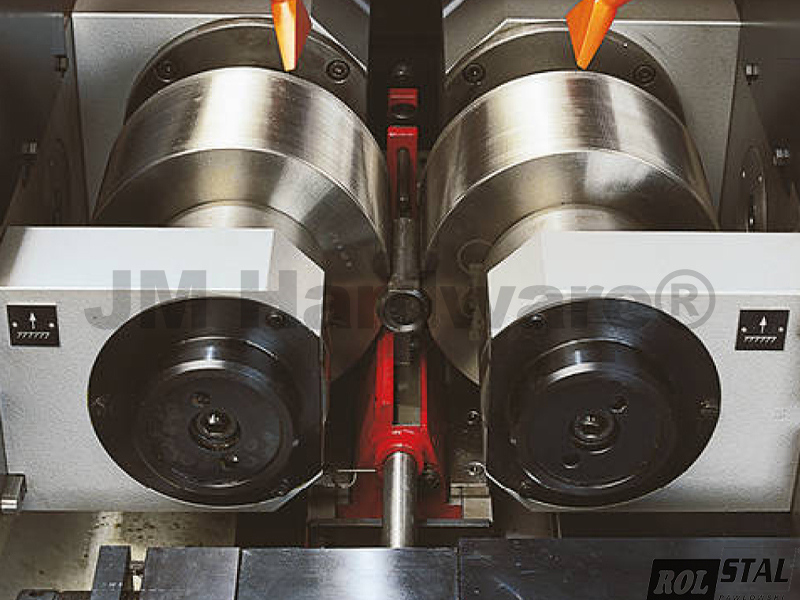

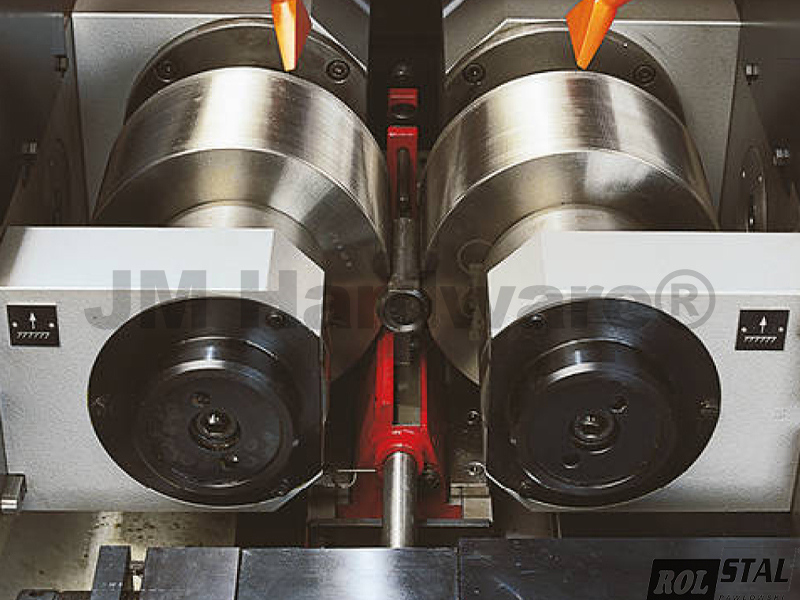

Forging:

The bolt heads are forged to ensure uniformity and structural integrity.

-

Thread Rolling:

Threads are rolled to enhance strength and prevent material weakening.

-

Heat Treatment:

Bolts are heat-treated to achieve the desired hardness and tensile strength.

-

Surface Treatment:

Coatings are applied to improve corrosion resistance and durability.

-

Final Inspection:

Each bolt undergoes rigorous testing and inspection to meet customer specifications.

Why Choose JM Hardware® as Your Hex Flange Bolt Manufacturer?

1.Custom Solutions: We offer tailored fasteners for specific construction needs, ensuring compatibility with your project requirements.

2.Wide Range of Products: From standard to high-strength and corrosion-resistant bolts, we offer an extensive selection of concrete bolts.

3.High-Quality Materials: Our bolts are made from high-quality materials for optimal strength, durability, and corrosion resistance.

4.Global Reach: We provide fasteners to construction projects around the world, ensuring timely delivery and availability.

5.Comprehensive Support: From product selection to post-delivery assistance, we provide end-to-end support for your concrete bolt needs.

6.Competitive Pricing: We offer high-quality bolts at competitive prices to fit your budget while maintaining exceptional performance.

Contact JM Hardware® for Hex Flange Bolt Solutions

Looking for a reliable hex flange bolt manufacturer? At JM Hardware®, we are committed to delivering superior products and exceptional customer service. Contact us today to discuss your requirements, request a quote, or learn more about our bolt manufacturing capabilities. Let us be your trusted partner for all your fastening needs!