-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we pride ourselves on being a leading hex bolt manufacturer, providing precision-engineered solutions to meet the diverse needs of global industries. Hex bolts are among the most widely used fasteners due to their versatility, strength, and reliability, and we deliver both standard and custom solutions for projects of all scales. With state-of-the-art manufacturing facilities, extensive material options, and strict quality control, JM Hardware® is your go-to source for hex bolts that meet the highest industry standards.

Why Choose JM Hardware® as Your Hex Bolt Manufacturer?

1.Comprehensive Product Range: From standard hex bolts to fully customized solutions, we cater to every need.

2.Global Delivery Network: With years of export experience, we deliver to customers worldwide with fast turnaround times.

3.Custom Manufacturing Capabilities: Tailored designs, unique materials, and surface treatments to suit your specific application.

4.Quality You Can Trust: Rigorous testing ensures every hex bolt meets international standards and exceeds your expectations.

5.Competitive Pricing: Advanced production techniques enable us to deliver premium-quality bolts at affordable prices.

Hex Bolt Varieties Offered by JM Hardware®

We produce a wide variety of hex bolts to meet the specific needs of various industries, including:

-

Fully Threaded Hex Bolts:

Ideal for applications requiring adjustable fastening and enhanced grip.

-

Partially Threaded Hex Bolts:

Designed for applications needing extra strength in the unthreaded portion.

-

Heavy Hex Bolts:

With a larger head and higher strength, perfect for demanding industrial applications.

-

High-Tensile Hex Bolts:

Made from alloy steel or other materials for maximum strength and load capacity.

-

Custom Hex Bolts:

Manufactured to meet non-standard sizes, shapes, and thread specifications for unique project needs.

Materials Used for Hex Bolt Manufacturing

Headed anchor bolts must endure significant loads, environmental factors, and prolonged use. At JM Hardware®, we manufacture bolts in a variety of materials to suit different applications:

-

Carbon Steel:

Widely used for general construction, offering excellent tensile strength and cost-effectiveness.

-

Stainless Steel (SS304, SS316):

Provides superior corrosion resistance, making it ideal for marine, chemical, and outdoor applications.

-

Alloy Steel:

Perfect for high-load scenarios due to its exceptional strength and durability.

-

Titanium:

Lightweight, strong, and highly resistant to corrosion, making it suitable for aerospace and high-performance industries.

-

Aluminum:

7.Lightweight and corrosion-resistant, commonly used in the automotive and construction sectors.

-

Duplex Stainless Steel:

Combines strength and corrosion resistance, suitable for harsh industrial environments.

-

Nickel-Based Alloys (Inconel, Monel, Hastelloy):

These alloys excel in extreme conditions, such as high temperatures and corrosive environments.

-

Brass:

Known for its corrosion resistance and conductivity, used in electrical and decorative applications.

Surface Finishes for Hex Bolts

We provide a variety of surface treatments to enhance the durability, appearance, and performance of our hex bolts:

-

Zinc Plating:

Provides a protective barrier against rust and corrosion, ideal for indoor or light-duty environments.

-

Hot-Dip Galvanizing:

Exceptional corrosion resistance, suitable for outdoor and marine applications.

-

Teflon Coating:

Provides excellent chemical resistance and smooth installation.

-

Dacromet Coating:

Advanced anti-corrosion coating, often used in automotive and construction applications.

-

Black Oxide Coating:

Adds a sleek, dark finish with moderate rust protection for indoor use./span>

-

Passivation:

Enhances the natural corrosion resistance of stainless steel bolts.

-

Powder Coating:

A durable and aesthetic finish, available in a variety of colors.

Applications of Hex Bolts

Hex bolts are versatile and used across a wide range of industries and applications, including:

-

Construction

Securing beams, columns, and panels in buildings, bridges, and other structures.

-

Oil & Gas

Used in pipeline assembly, refineries, and offshore platforms due to their high strength and corrosion resistance.

-

Aerospace

Hex bolts made from high-strength materials like titanium are used in aircraft assembly and maintenance.

-

Automotive

Commonly used in engines, frames, and suspension systems.

-

Heavy Machinery

Provides durable fastening solutions for industrial equipment and machinery.

-

Renewable Energy

Essential for securing components in wind turbines and solar panel structures.

-

Agriculture

Securing heavy-duty equipment like tractors and plows.

-

Marine Applications

Corrosion-resistant hex bolts are used in shipbuilding and offshore applications.

-

Electrical Systems

Fastening components in electrical transmission and utility projects.

Standards and Grades for Hex Bolts

All our hex bolts are manufactured to meet international quality and dimensional standards, including:

-

ISO 898(International Organization for Standardization)

Global standards for bolt design and performance.

-

DIN (Deutsches Institut für Normung)

European fastener dimensions and mechanical properties.

-

ASTM (American Society for Testing and Materials)

Specifications for mechanical properties and material requirements.

-

ANSI/ASME (American National Standards Institute)

North American standards for dimensions and tolerances.

-

BS (British Standards)

Standardized dimensions and performance for bolts used in the UK.

-

JIS (Japanese Industrial Standards)

Fastener standards commonly used in the automotive and electronics industries.

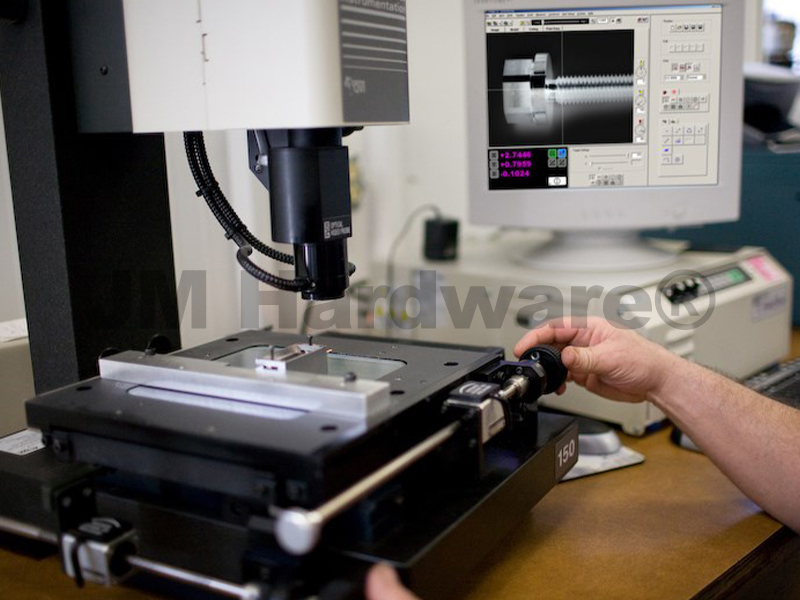

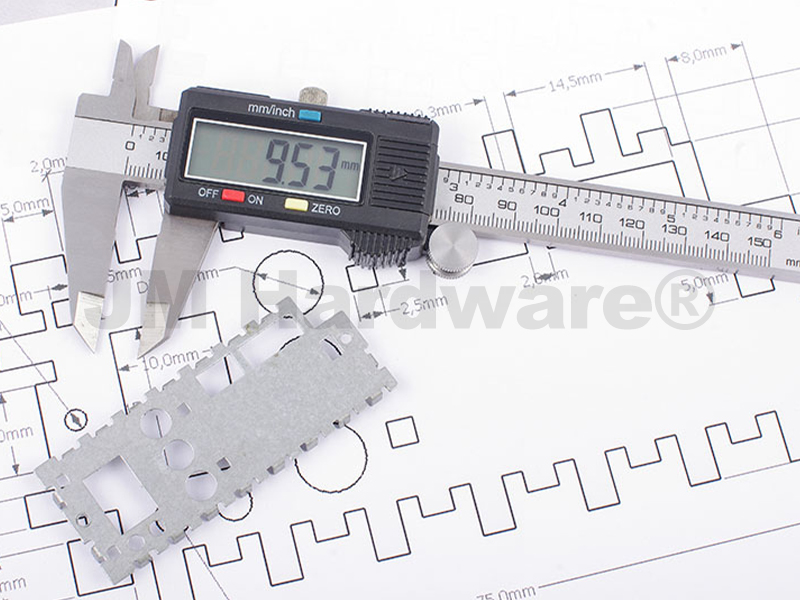

Quality Assurance and Testing

At JM Hardware®, we perform rigorous quality checks on every hex bolt to ensure it meets or exceeds industry standards. Our testing methods include:

-

Tensile Testing:

Ensures bolts can handle high loads and stress.

-

Salt Spray Testing

Evaluates corrosion resistance, especially for coated bolts.

-

Vibration Testing:

Ensures stability under dynamic loads and vibrations.

-

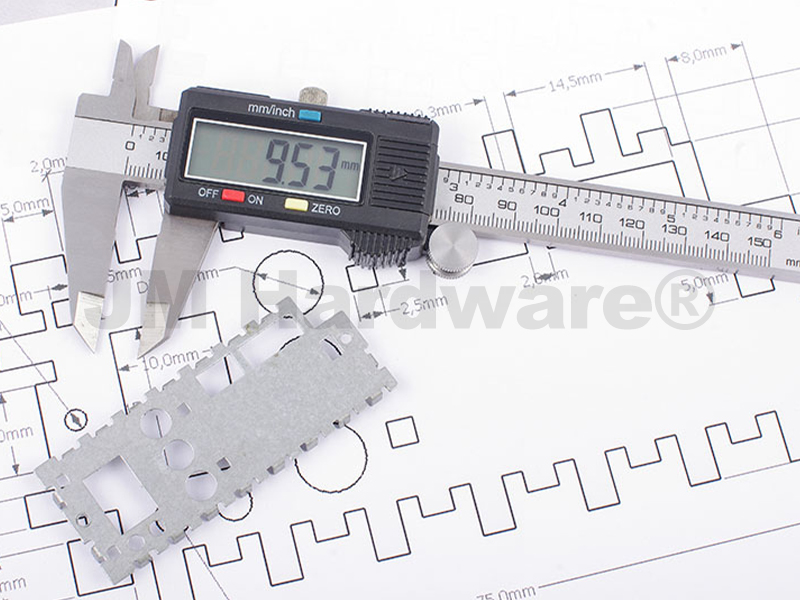

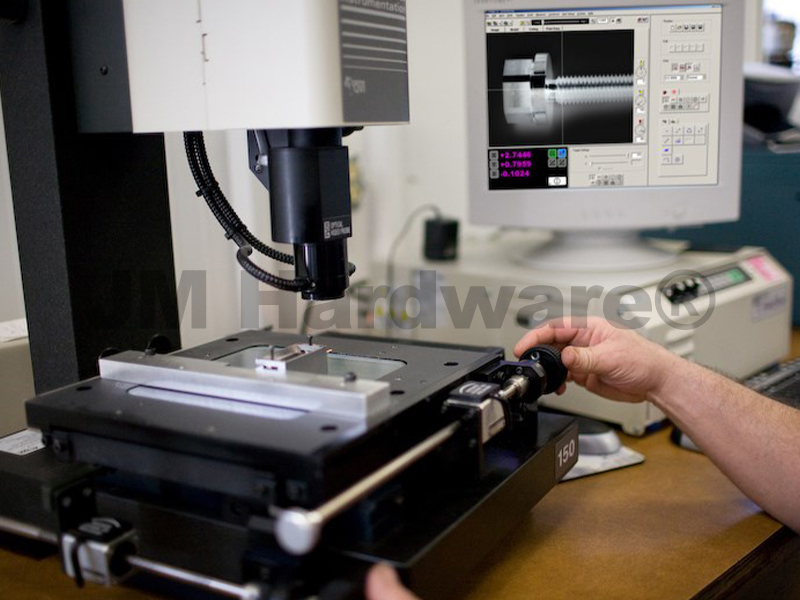

Dimensional Accuracy Testing:

Confirms precise thread pitch, diameter, and length.

-

Impact Testing:

Assesses bolt performance under sudden impact or shock loads.

-

Hardness Testing:

Verifies the material meets required hardness levels.

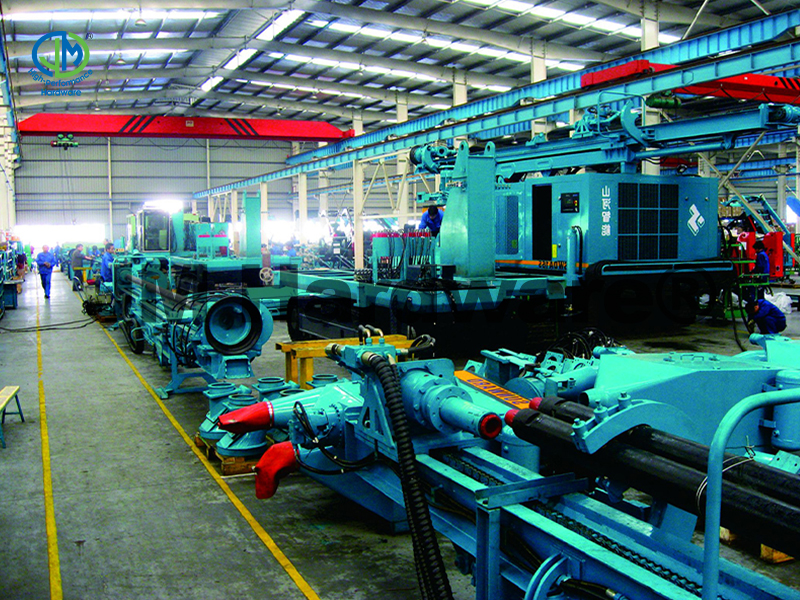

Manufacturing Process for Hex Bolts

As a leading headed anchor bolt manufacturer, we utilize advanced production processes to deliver consistent, high-quality products:

-

Material Selection:

Only high-quality raw materials are used, selected to meet your project’s specific needs.

-

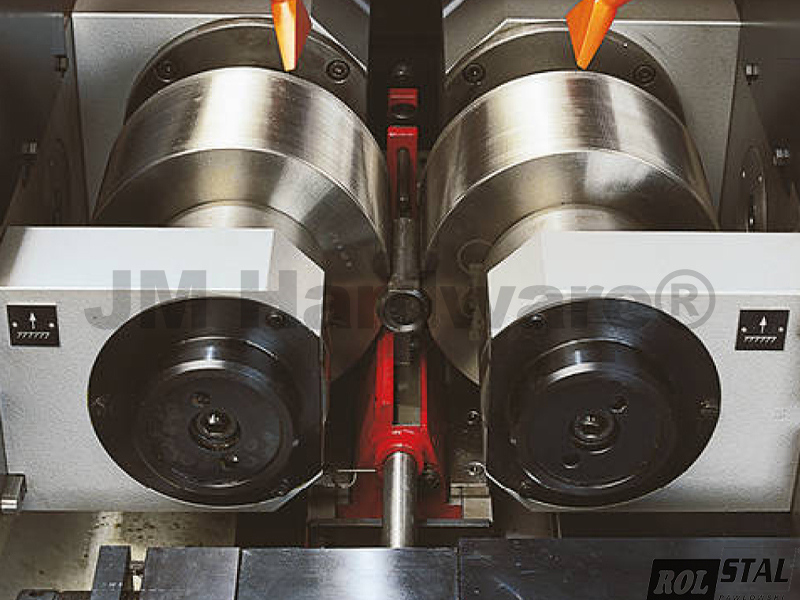

Forging:

Hex heads are formed using advanced cold or hot forging techniques.

-

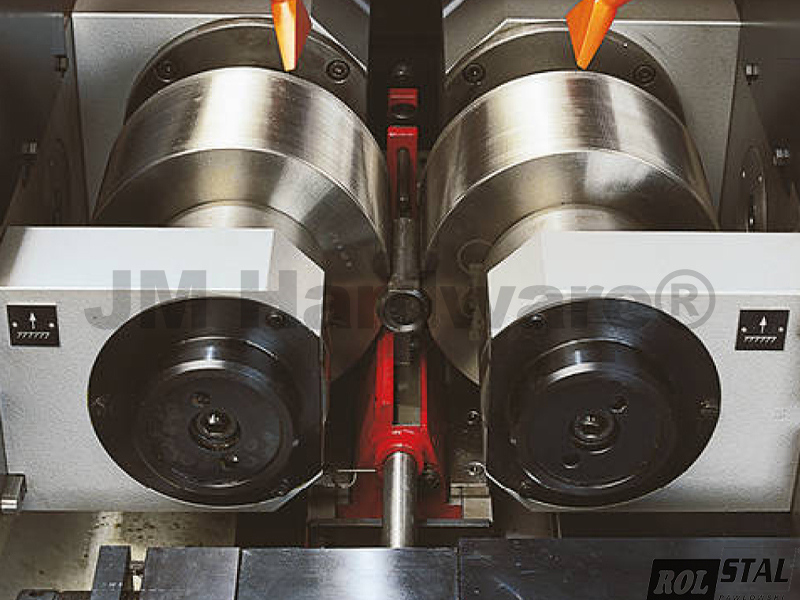

Thread Rolling:

Threads are rolled to enhance strength and prevent material weakening.

-

Heat Treatment:

Bolts are heat-treated to achieve the desired hardness and tensile strength.

-

Surface Treatment:

Coatings are applied to improve corrosion resistance and durability.

-

Final Inspection:

Each bolt undergoes rigorous testing and inspection to meet customer specifications.

Why Choose JM Hardware® as Your Hex Bolt Manufacturer?

1.Custom Solutions: We offer tailored fasteners for specific construction needs, ensuring compatibility with your project requirements.

2.Wide Range of Products: From standard to high-strength and corrosion-resistant bolts, we offer an extensive selection of concrete bolts.

3.High-Quality Materials: Our bolts are made from high-quality materials for optimal strength, durability, and corrosion resistance.

4.Global Reach: We provide fasteners to construction projects around the world, ensuring timely delivery and availability.

5.Comprehensive Support: From product selection to post-delivery assistance, we provide end-to-end support for your concrete bolt needs.

6.Competitive Pricing: We offer high-quality bolts at competitive prices to fit your budget while maintaining exceptional performance.

Contact JM Hardware® for Hex Bolt Solutions

Looking for a trusted hex bolt manufacturer? JM Hardware® delivers high-quality hex bolts for construction, industrial, and specialized applications. Contact us today for more information, or request a quote to get started on your next project. Trust JM Hardware® for all your fastener needs!