-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

At JM Hardware®, we are a trusted bolt manufacturer specializing in high-quality bolts with internal threads designed for a wide range of applications across various industries. Our bolts with internal threads are engineered for precision, strength, and reliability, offering seamless solutions for fastening, joining, and securing components in a variety of assemblies. Whether you require standard or custom solutions, our extensive experience and state-of-the-art manufacturing processes ensure that we deliver fasteners that meet your specific needs.

Different Names for Bolts with Internal Threads

Bolts with internal threads are commonly referred to by different names depending on their design and application. Some of the most widely used terms include:

-

Internal Thread Bolts

-

Bolt with Nut Insert

-

Bolt with Threaded Hole(for square pipes and channels)

-

Tapped Bolts

-

Bolt with Female Thread(customized to specific dimensions or finishes)

-

Threaded End Bolts(customized to specific dimensions or finishes)

These bolts have a threaded hole at one end, allowing them to accept another bolt or screw, facilitating secure connections in various applications.

Materials Used in Bolt Manufacturing

As a bolt manufacturer, we offer bolts with internal threads in a wide variety of materials, each designed to meet the specific performance requirements of your project. Common materials include:

-

Carbon Steel:

Known for its strength and affordability, carbon steel is commonly used in general applications where high corrosion resistance is not a primary concern.

-

Stainless Steel (SS304, SS316):

Stainless steel bolts offer excellent corrosion resistance and are ideal for marine, chemical, and high-humidity environments.

-

Alloy Steel:

Provides superior strength and durability, perfect for heavy-duty applications in machinery, construction, and automotive industries.

-

Duplex Stainless Steel:

This material offers higher strength and better corrosion resistance, making it ideal for extreme environments.

-

Brass:

Non-magnetic and corrosion-resistant, suitable for applications in electrical industries or where conductivity is important.

-

Titanium:

Offers exceptional strength-to-weight ratio, ideal for high-performance industries like aerospace and medical.

-

Aluminum:

Lightweight and corrosion-resistant, commonly used for applications that require a balance between strength and weight.

Surface Finishes for Bolts with Internal Threads

To increase the durability and performance of bolts with internal threads, we offer a variety of surface treatments. These coatings are designed to enhance corrosion resistance, reduce wear, and improve performance:

-

Zinc Plating:

Provides moderate protection against corrosion, typically used for indoor and general-purpose applications.

-

Hot-Dip Galvanizing:

Provides excellent corrosion resistance, ideal for outdoor and marine applications.

-

Black Oxide Coating:

Offers a sleek finish with a layer of protection against corrosion, often used for aesthetic purposes and light-duty applications.

-

Teflon Coating:

Offers excellent resistance to corrosion and chemical exposure, ideal for industries such as oil and gas.

-

Phosphate Coating:

Offers corrosion resistance and lubrication for industrial and automotive applications.

-

Epoxy Coating:

Provides a robust layer of protection against harsh environmental conditions, including chemicals and extreme temperatures.

-

Passivation(for stainless steel):

Especially useful for stainless steel bolts, this process enhances the material’s natural resistance to corrosion.

Grades of Bolts with Internal Threads

As a leading bolt manufacturer, we provide bolts with internal threads in various grades, depending on their strength and application requirements. Common grades include:

-

Grade 4.8, 8.8, 10.9, and 12.9 (Carbon Steel)

Ideal for general construction and light-duty applications.

-

Grade A193 B7, B7M (Alloy Steel)

High-strength bolts used in high-pressure and high-temperature environments, such as in the oil and gas industry.

-

ASTM A193

Suitable for use in petrochemical, power generation, and heavy industrial applications.

-

ASTM A320 Grade L7:

Low-temperature grade bolts for applications in cold environments, such as cryogenic systems.

-

Grade 8.8 and 10.9(Alloy Steel)

Used in industrial machinery and heavy-duty applications that require high tensile strength. 4.ASTM A193 – Suitable for use in petrochemical, power generation, and heavy industrial applications.

-

A4-70, A4-80 (Stainless Steel)

Designed for marine environments, where superior corrosion resistance is critical.

Standards for Bolts with Internal Threads

To ensure the highest level of quality and reliability, our bolts with internal threads are manufactured to meet a variety of internationally recognized standards, including:

-

ISO 9001:

Ensures that all products meet rigorous quality management standards.

-

DIN(Deutsches Institut für Normung):

European standards for bolt dimensions, mechanical properties, and testing.

-

ASTM (American Society for Testing and Materials):

Specifies the mechanical properties, dimensions, and standards for bolts used in various industries.

-

BS (British Standards):

Defines the standards for bolt performance, materials, and dimensions in the UK.

-

JIS (Japanese Industrial Standards):

Standards for the mechanical properties and dimensions of bolts in industrial applications.

-

SAE (Society of Automotive Engineers):

Standards for bolts used in automotive applications.

Applications of Bolts with Internal Threads

Our bolts with internal threads are ideal for a wide variety of applications across numerous industries. Some of the common uses include:

-

Automotive Industry:

Connecting parts and components, such as engine blocks, transmission systems, and suspension systems.

-

Aerospace:

Used for fastening delicate components with precision and reliability in aircraft and satellite assemblies.

-

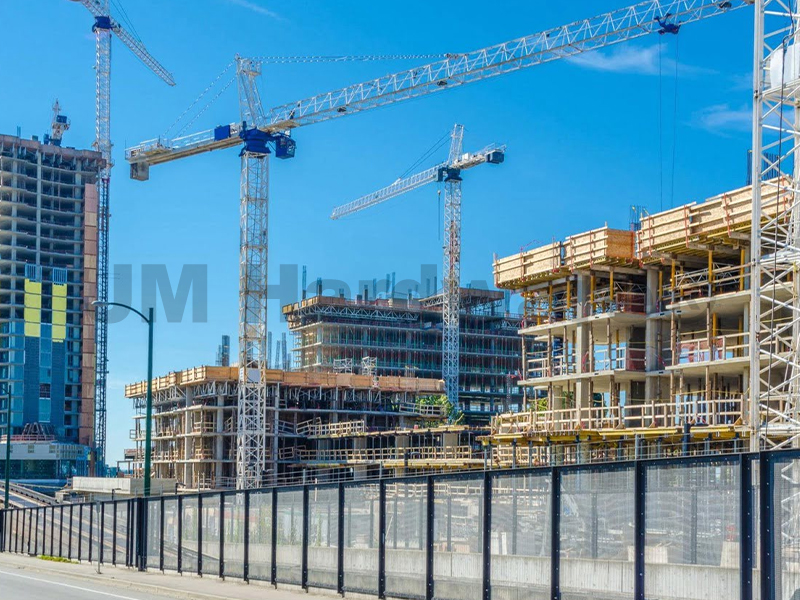

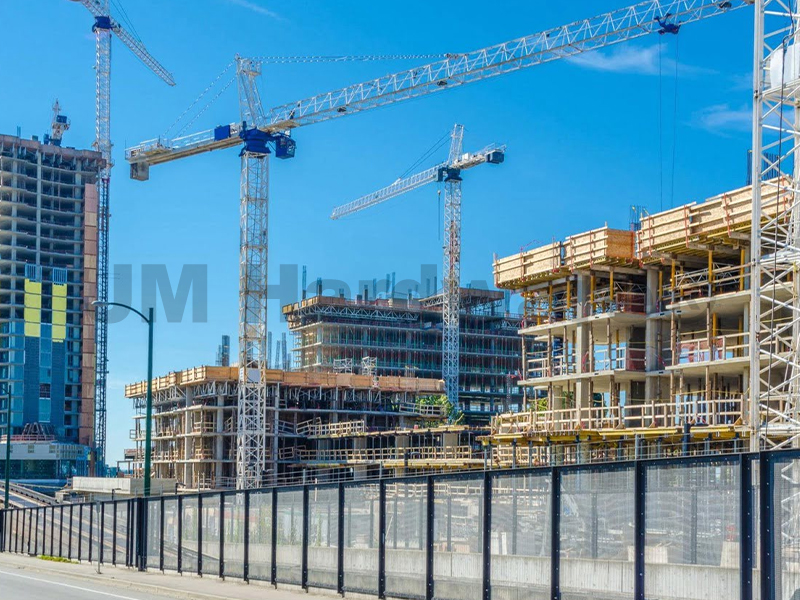

Construction:

Securing structural elements such as beams, columns, and panels in buildings and bridges.

-

Electronics:

Connecting components in circuit boards and enclosures, where space and precision are critical.

-

Renewable Energy:

Connecting components in wind turbines, solar panel structures, and other clean energy systems.

-

Marine

Fastening parts in boats, ships, and offshore platforms where corrosion resistance is paramount.

-

Industrial Equipment:

Used in heavy machinery and equipment where high strength and durability are essential.

Testing Methods for Bolts with Internal Threads

To guarantee the performance, strength, and reliability of our bolts with internal threads, we subject them to a series of rigorous testing methods:

-

Tensile Strength Testing:

To verify that bolts can withstand the expected loads without failure.

-

Hardness Testing:

Ensures that the material meets the required hardness specifications for durability.

-

Corrosion Resistance Testing:

Measures the fastener’s ability to resist corrosion, particularly for stainless steel and galvanized bolts.

-

Dimensional Inspection:

Ensures that the bolt is manufactured within the specified tolerances for thread quality and size.

-

Impact Testing:

Verifies the bolt’s performance under high-impact conditions.

-

Fatigue Testing:

Assesses the bolt’s ability to withstand repeated stress and load cycles over time.

Production Process for Bolts with Internal Threads

At JM Hardware®, our production process for bolts with internal threads is designed to ensure maximum precision and strength:

-

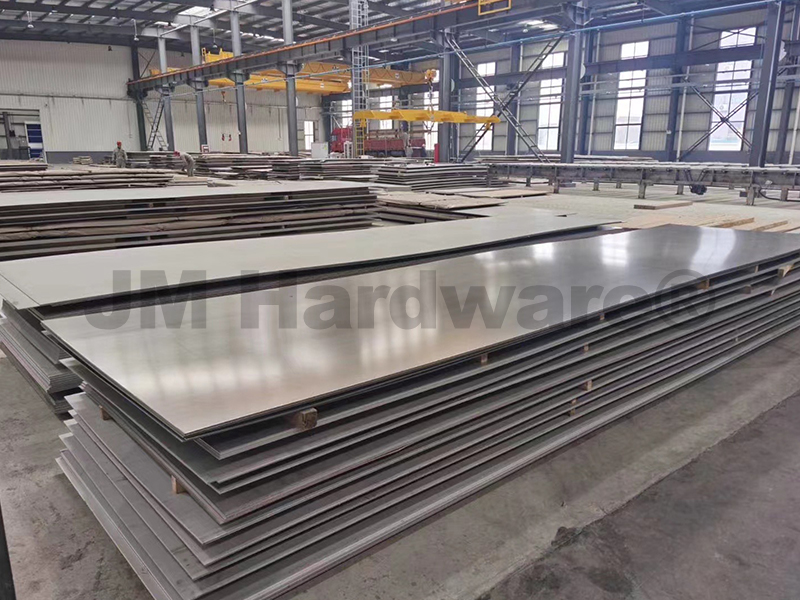

Material Selection:

Premium raw materials are carefully selected to meet the specific strength, corrosion resistance, and durability requirements of each application.

-

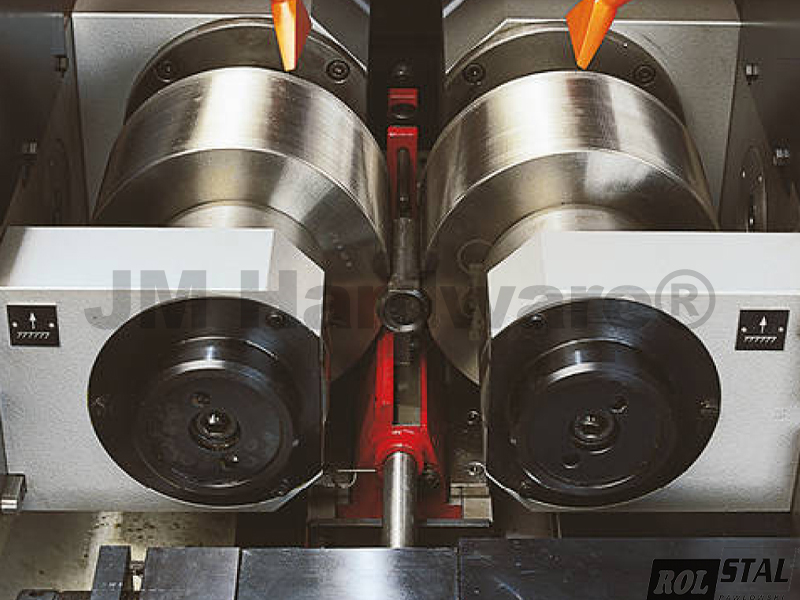

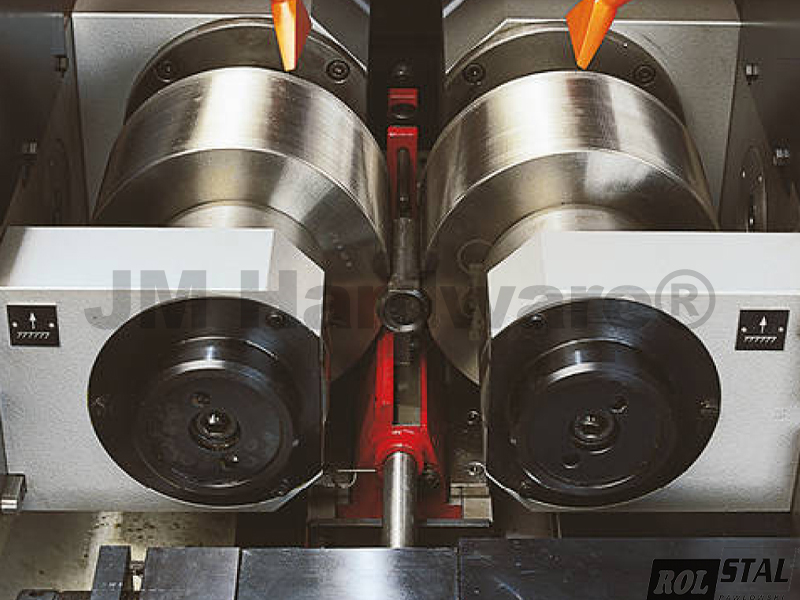

Thread Rolling:

Threads are rolled onto the bolts rather than being cut, increasing strength and minimizing material wastage.

-

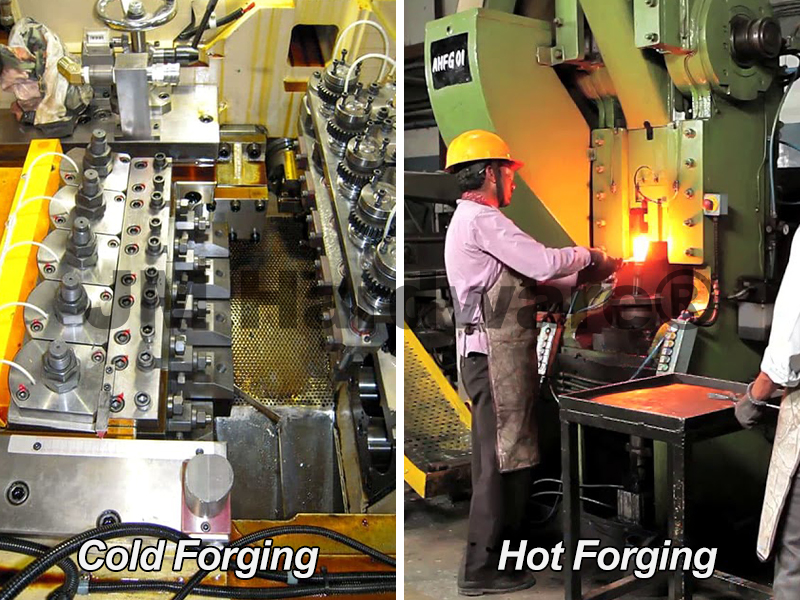

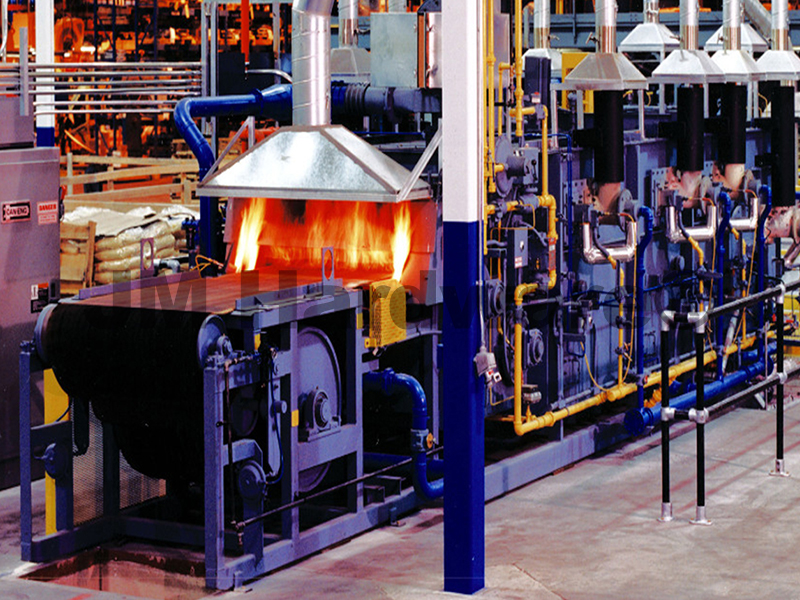

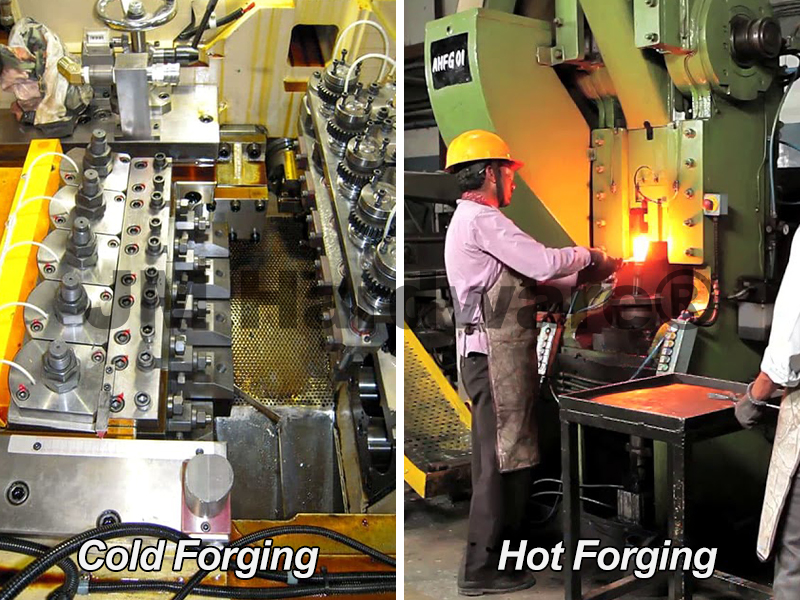

Cold or Hot Forging:

Depending on the application, bolts are either cold or hot forged to achieve the desired strength and shape.

-

Heat Treatment:

Heat treatment is applied to enhance the mechanical properties and increase the durability of the bolts.

-

Surface Treatment:

Coatings are applied to enhance corrosion resistance and wear resistance.

-

Quality Control:

Each bolt undergoes comprehensive testing and inspection to ensure that it meets the required specifications.

Why Choose JM Hardware® as Your Bolt Manufacturer?

1.Custom Solutions: We offer tailored solutions for unique applications with non-standard sizes, materials, and coatings.

2.Wide Range of Materials: From carbon steelto titanium, we offer bolts made from a variety of materials to suit different environments and load requirements.

3.Expert Manufacturing: Our state-of-the-art manufacturing process ensures high precision and quality in every bolt with internal threads.

4.Global Delivery: We ship to projects around the world, ensuring timely delivery and product availability.

5.Strict Quality Control: All our bolts are rigorously tested to ensure they meet industry standards and customer specifications.

6.Competitive Pricing: With efficient production and sourcing, we offer premium quality at competitive prices.

Contact JM Hardware® for Bolt with Internal Thread Needs

Whether you need custom bolts with internal threads for aerospace, construction, automotive, or industrial applications, JM Hardware® has the solutions you need. Contact us today to discuss your project requirements or request a quote. Trust JM Hardware® as your reliable bolt manufacturer for high-quality, precision-engineered fasteners.