-

Export 85+countriesUSA Trade Mark

Export 85+countriesUSA Trade Mark -

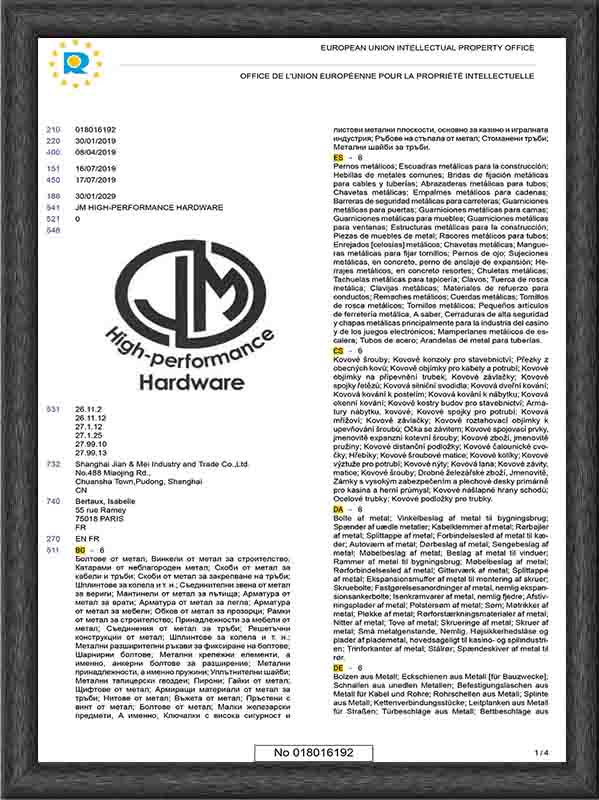

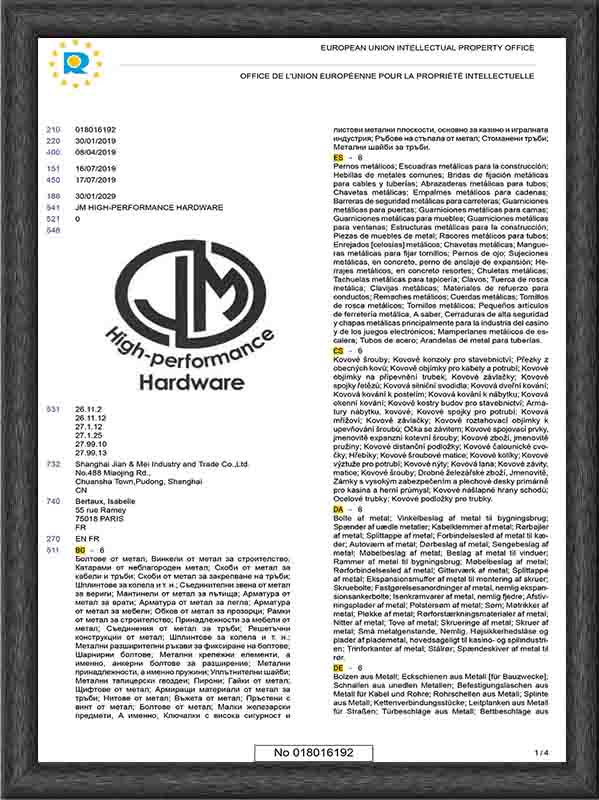

18 years R&D 850+ Custom partsEU Trade Mark

18 years R&D 850+ Custom partsEU Trade Mark -

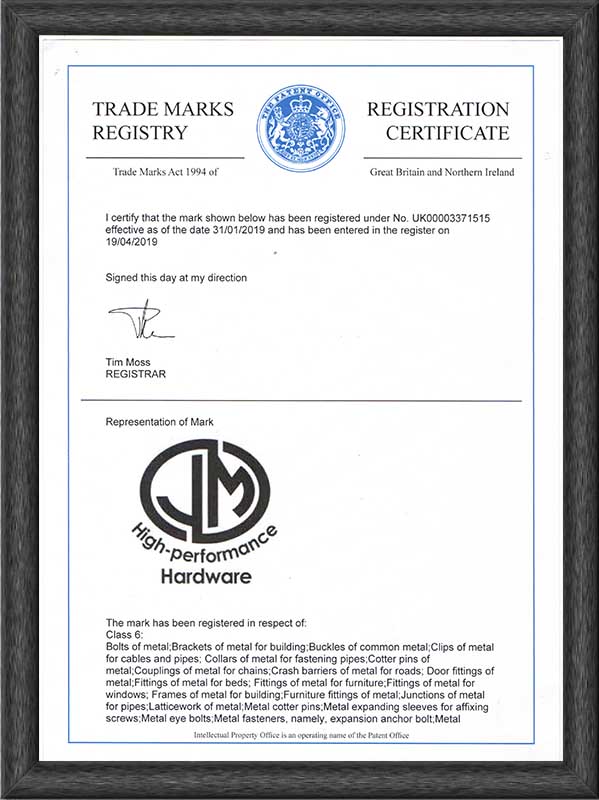

Help 1000+ oversea customersUK Trade Mark

Help 1000+ oversea customersUK Trade Mark

-

Sharp cutting edge, easy to install

-

Smooth thread without burss

-

Clear corners beautiful & durables

-

Yellow Zinc Strong anti-corrosion

JM Hardware® provides free samples of the above products during the Black Friday event. If you have any demand for these products, please contact our email: xarella.huang@jm-industry.com

Brand Story

The inception of the JM Hardware® brand was a profound moment born out of a fateful business trip. During a trip abroad, I was flipping through a newspaper when I came across a heartbreaking story about a steel building that had collapsed due to a batch of substandard fasteners. The tragic images and casualties left an indelible mark on me.

From that moment on, our commitment to putting product quality first became a cornerstone of JM Hardware®, engraved in the DNA of our brand. With this unwavering commitment, JM Hardware® set out to set a new standard for quality. We spend countless hours researching, developing, and testing each product to ensure that they not only meet industry standards, but that they also meet the company's own higher standards. This journey is driven not by profit, but by a deep sense of responsibility - the responsibility to protect a person, a family, a community.

JM Hardware® stands as a testament to that enduring commitment. Every product that bears the JM Hardware® name will be synonymous with excellence, durability and safety.

JM Hardware®: the combination of quality and integrity.

-------- Mrs. Xarella Huang

General President

-

2006Established

2006Established -

34000TProduction Quantity Each Year

34000TProduction Quantity Each Year -

85+Export Country

85+Export Country -

850 +R&D New Products

850 +R&D New Products

-

Supply one-stop service & DDP termHelp clients purchase other products,realize door-to-door service to make international procurement more convenient

Supply one-stop service & DDP termHelp clients purchase other products,realize door-to-door service to make international procurement more convenient -

Strong R&D CapabilitySuccessfully developed 850+ new products in past 18 years

Strong R&D CapabilitySuccessfully developed 850+ new products in past 18 years -

Mature & professional service teamsProvides 24/7 online and offline services for you,70%stuff have 5+ working experience in JM

Mature & professional service teamsProvides 24/7 online and offline services for you,70%stuff have 5+ working experience in JM -

Rich Industry ExperienceJM has the rich experience to supply the high quality fasteners to Project contractor

Rich Industry ExperienceJM has the rich experience to supply the high quality fasteners to Project contractor -

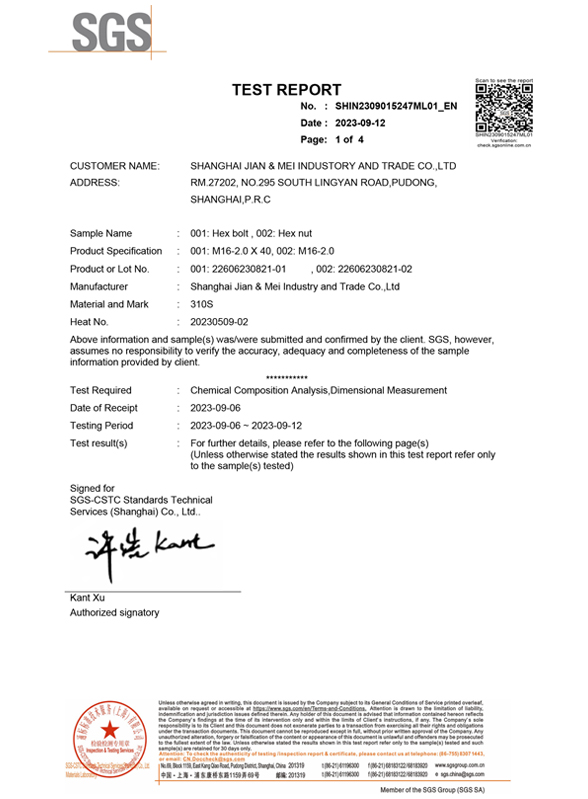

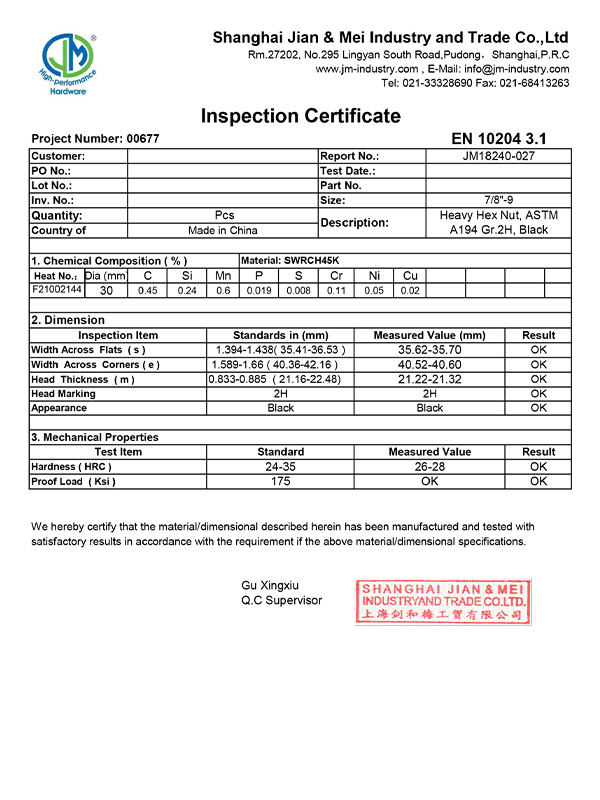

Registered trademarksRegister JM Hardware ® in USA,EU ,UK,Quality Assurance

Registered trademarksRegister JM Hardware ® in USA,EU ,UK,Quality Assurance -

Rich export experience18 years exported to 85+ countries

Rich export experience18 years exported to 85+ countries

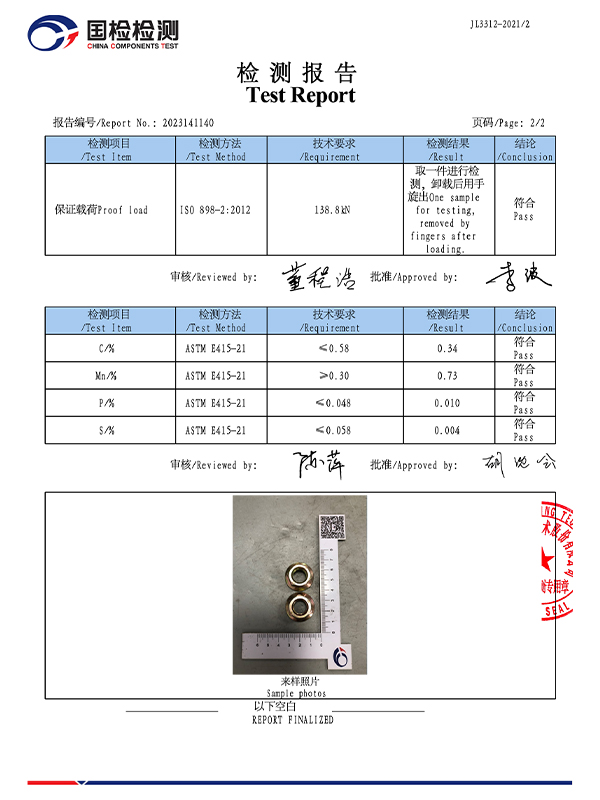

JM Hardware conducts product quality

control in strict accordance with ISO 9001 standards to ensure that our

products meet high quality standards. Below are our five quality control steps:

Step 1: Incoming material control

We carry out strict incoming material control by conducting dimensional tests

on each batch of raw materials and checking the raw material reports from the

steel mills. This ensures that the raw materials we use are within

specification and provide a reliable basis for production.

Step 2: First part control

After the mold assembly is completed, we conduct a thorough inspection of the

first production part and make detailed records. Only qualified first parts can

be released to start mass production. This step ensures that the quality of the

product meets the standard at the beginning.

Step 3: Self-inspection by workers during mass production

In the mass production process, we require the workers of each machine to carry

out self-inspection every hour. If any substandard product is found, we will

immediately pick or scrap the production within this hour until the problem is

solved and meets the standard of conformity, and then we can continue the

production. This self-inspection mechanism helps to find and solve problems in

time during the production process.

Step 4: QC inspection during mass production

In addition, every two hours, the quality inspection personnel will carry out

random inspection on the products of each machine. Only qualified products can

continue to flow into the next production stage. If non-conforming products are

found, we will take the same selection or scrapping measures and ensure that

the problem is properly handled. This helps provide additional quality

assurance.

Step 5: Finished product control

Finally, after each batch of finished product is made, we conduct random

inspections in proportion to the order. Qualified products will be packaged and

put into storage, while unqualified products will be returned for further

analysis and rectification. We insist on ensuring that the quality of our

products meets high standards so that we can provide reliable products to our

customers.

Step 6: Non-conforming goods management

According to the process of JMhardware's non-conforming products handling, pick

or scrap. And the problem of rectification and tracking reasons to ensure that

non-conforming products will not flow into the market.

These quality control measures constitute JM Hardware's quality management system,

and we are constantly striving to improve the quality of our products and are

committed to meeting the needs of our customers. We believe that quality

control is the key to our success.

-

JM Small Box & JM Carton

-

Small bag with lable & Nature carton

-

Small box & Nature carton

-

90kgs Metal keg & Wood solid pallet

-

Wood case & Plastic keg with wood solid pallet

-

Fumigation wood pallets & Non fumigation pallets

-

Paper sleeve & Plastic bag + Non fumigation pallets

-

Wooden case& Woven bag + Non fumigation pallets

-

Container Packing

Our vision is to make JM Hardware® a well-known Chinese brand of high-end hardware parts in the world,and your cooperation will be an important part of it

If you do not see the product you need, or you have special customization requirements, you can send an email to xarella.huang@jm-industry.com. JM Hardware® will do our best to help you solve the problem

JM Hardware® Extruded U Nut/Metal U-Type Clip

JM Hardware® Extruded U Nut/Metal U-Type Clip

JM Hardware® DIN 7967 M4-M64 Pal Nut / Self Locking Counter Nut

JM Hardware® DIN 7967 M4-M64 Pal Nut / Self Locking Counter Nut

- Bolt

- Rod / Stud

-

Nut

- JM Hardware® Extruded U Nut/Metal U-Type Clip

- JM Hardware® DIN 7967 M4-M64 Pal Nut / Self Locking Counter Nut

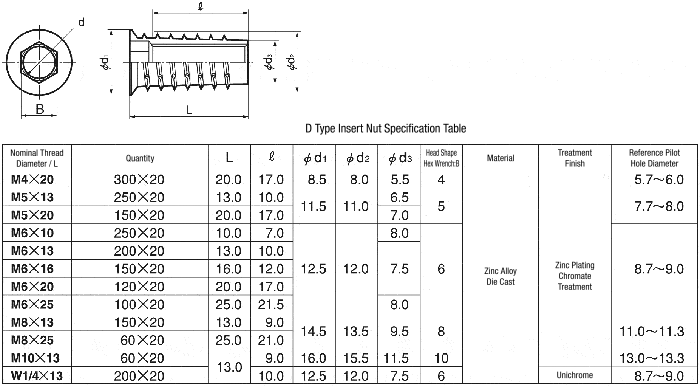

- JM Hardware® Furniture Embedded Insert Nut

- Rivet Nut

- Nylon Insert Lock Nut

- Wing Nut

- Hex Flange Nut

- Square Nut

- Cap Nut / Acorn Nut

- Hex Coupling Nut

- Hex Nut / Heavy Hex Nut

- Castle Nut / Hex Slotted Nut

- Washer

- Pin

- Screw

- Rivet

- Photovoltaic accessories