317/ 317L Stainless Steel Fasteners are austenitic stainless steel fasteners. The base elements in these fasteners are chromium and nickel. It also consists of molybdenum in higher concentrations in its alloy. The molybdenum present in it gives the fasteners great resistance towards corrosion pitting and corrosion cracking.

These fasteners are highly durable and show great tensile strength even at elevated temperatures. These fasteners can also prove the best in various acidic environments where corrosion could occur very easily. These fasteners can be available in different shapes, sizes, dimensions, structures depending upon the user specifications as well as the requirements of the product.

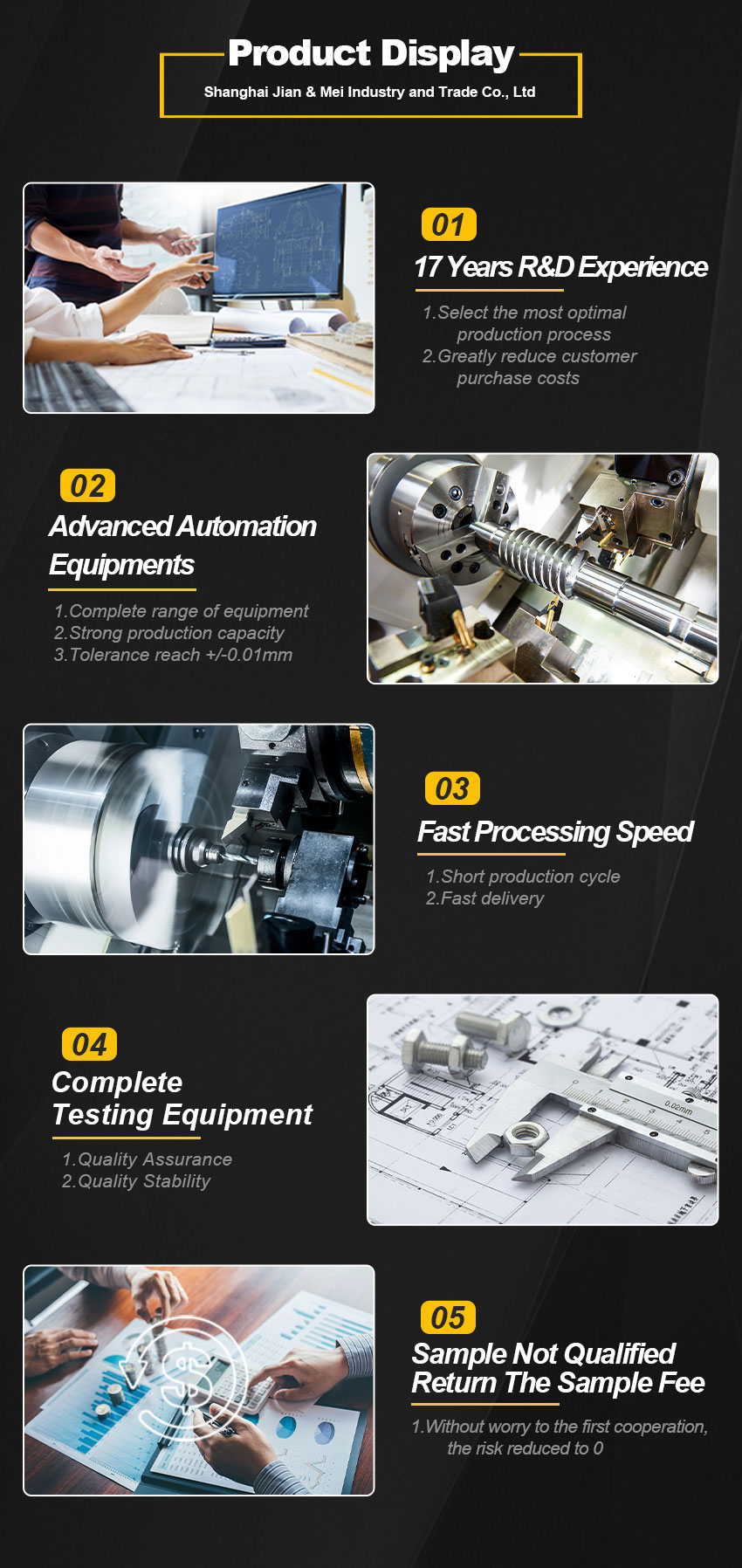

JM Hardware ® produces excellent quality 317/ 317L Stainless Steel Fasteners by keeping industrial standards in mind. These can work at high-temperature ranges. They are used in applications where great tensile strength is required at elevated temperatures. The surface of these fasteners has excellent finishing, and these fasteners are also very easy to maintain and cost-effective. These fasteners are also easily weldable as well as can be fabricated very easily.

317/ 317L Stainless Steel Fasteners are produced from high-quality raw materials in order to give an excellent finished product to the clients. These fasteners also undergo a number of destructive as well as non-destructive tests so that the best quality of fasteners are produced as these fasteners bear several properties. They are also used in a wide range of industrial applications.

|

Specification: Stainless Steel 317/ 317L Fasteners

|

|

|

Specifications

|

ASTM A 193 / ASME SA 193 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Fasteners Length | 3 mm - 200 mm | Custom Sizes |

| Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

Forms of Stainless Steel 310/310S Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

- Chemical Industries

- Oil & Gas Industrires

- Power Plant Industries

- Shipbuilding Industries

- Fertilizer Industrires

- Petrochemical Industrires

- Sugar Industrires

|

Equivalent

Grade: Stainless Steel 317/ 317L Fasteners

|

||||

|

STANDARD

|

UNS | WNR. | JIS | EN |

| SS 317 | S31700 | 1.4449 | SUS 317 | - |

| SS 317L | S31703 | 1.4438 | SUS 317L | X2CrNiMo18-15-4 |

|

Chemical

Composition: Stainless Steel 317/ 317L Fasteners

|

|||||||||

|

Grade

|

C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 317 | 0.08 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 14 | - |

| 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 15 | - |

|

Mechanical

Properties:- Stainless Steel 317/ 317L Fasteners

|

||||

|

Density

|

Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35% |

JM Hardware ® Stainless Steel 310/310S Fasteners

JM Hardware ® Stainless Steel 310/310S Fasteners

JM Hardware ® Stainless Steel 314 (UNS S31400) W. Nr. 1.4841 Fasteners

JM Hardware ® Stainless Steel 314 (UNS S31400) W. Nr. 1.4841 Fasteners

JM Hardware ® Stainless Steel 904L (UNS N08904) W. Nr. 1.4539 Fasteners

JM Hardware ® Stainless Steel 904L (UNS N08904) W. Nr. 1.4539 Fasteners