Material Excellence: Stainless Steel 314, known for its exceptional corrosion resistance and heat resistance, forms the backbone of our fasteners. This alloy is particularly well-suited for applications where exposure to extreme temperatures and harsh environments is commonplace. Its high chromium and nickel content, coupled with molybdenum, provides superior resistance to oxidation and corrosion, making it ideal for outdoor and marine applications.

Key Features:Our Stainless Steel 314 fasteners offer a range of essential attributes:

Corrosion Resistance: Unmatched protection against rust and corrosion, ensuring a longer lifespan in challenging environments.

High Heat Tolerance: Maintains structural integrity in extreme heat, making it ideal for high-temperature applications.

Chemical Stability: Withstands exposure to various chemicals without degradation.

Strength and Reliability: High tensile strength and durability guarantee dependable performance.

Low Maintenance: Requires minimal upkeep, reducing operational costs.

Forms of Stainless Steel 314 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

Our Stainless Steel 314 fasteners find extensive utility across diverse industries:

Marine Environments: Stainless Steel 314's resistance to saltwater corrosion makes it indispensable for marine equipment and vessels.

High-Temperature Applications: With its excellent heat resistance, these fasteners are perfect for use in furnaces, kilns, and exhaust systems.

Chemical Processing: Stainless Steel 314 excels in environments exposed to chemicals and acids, ensuring longevity and safety.

Power Generation: Fasteners in power plants and energy facilities benefit from its high-temperature durability.

Outdoor Structures: Whether it's bridges, railings, or architectural elements, these fasteners stand up to the elements.

|

|||||||

| AFNOR Z 12 CNS 25.20 | DIN 1.4841 | UNI X 16 CrNiSi 25 20 | UNI X 22 CrNi 25 20 | JIS SUS Y 31O | |||

| B.S. 310 S 24 | AMS 5522 | AMS 5652 | ASTM A276 | ASTM A314 | |||

| ASTM A473 | ASTM A580 | SAE 30314 | SAE J405 (30314) | ||||

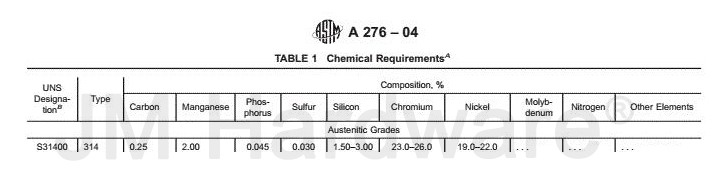

| Chemical Composition | |

| Element | Content (%) |

| Iron, fe | Balance |

| Chromium, Cr | 23-26 |

| Nickel, Ni | 19-22 |

| Manganese, Mn | 2 |

| Silicon, Si | 1.5-3 |

| Carbon, C | 0.25 |

| Sulfur, S | 0.03 |

| Phosphorous, P | 0.045 |

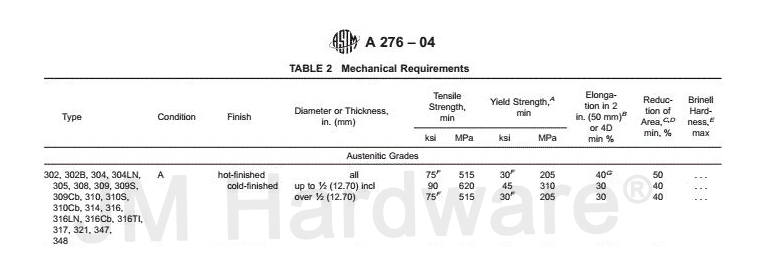

| Mechanical Properties | ||

| Properties | Metric | Imperial |

| Tensile strength | 689 MPa | 99900 psi |

| Yield strength | 345 MPa | 50000 psi |

| Modulus of elasticity | 200 GPa | 29000 ksi |

| Elongation at break (in 50 mm) | 40% | 40% |

| Hardness, Rockwell B | 85 | 85 |

JM Hardware ® Stainless Steel 310/310S Fasteners

JM Hardware ® Stainless Steel 310/310S Fasteners

JM Hardware ® Stainless Steel 317/ 317L Fasteners

JM Hardware ® Stainless Steel 317/ 317L Fasteners

JM Hardware ® Stainless Steel 904L (UNS N08904) W. Nr. 1.4539 Fasteners

JM Hardware ® Stainless Steel 904L (UNS N08904) W. Nr. 1.4539 Fasteners