JM Hardware ® Stainless Steel 904L (UNS N08904) W. Nr. 1.4539 Fasteners

Stainless Steel 904L Fasteners is a member of the alloy steel family, which conservatively possess 10 per cent to 30 per cent of chromium element. This element offers extended resistance towards heat and corrosive condition, being low by the proportion of carbon. Exclusive elements like sulphur, aluminium, and titanium work as great support for 904L Stainless Steel Fasteners’ strength.

Stainless Steel Din 1.4539 Fasteners is the fundamental identity of Stainless Steel 904L Fasteners, which has a good amount of selenium and copper added with the solution of phosphorus to improve the resistance property. However, the oxidation has a player named resistance to fight in a severe condition which is held by the rest purities added in the SS 904L Fasteners. Attributes are the most important identity for which UNS NO8904 Fasteners are in huge demand, especially the power to tackle in a high-temperature environment.

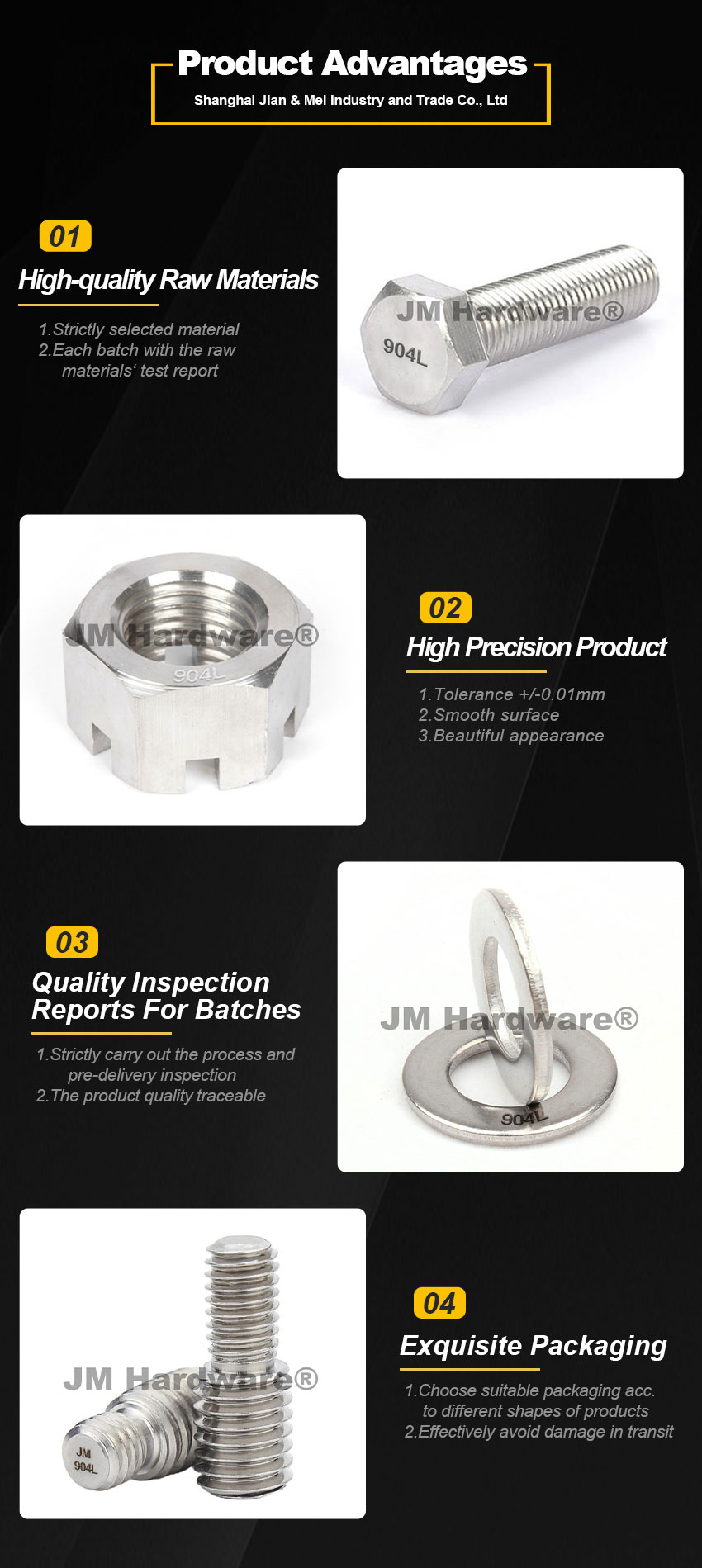

Alloy 904L Fasteners are usually taken in the process of melting in electric arc furnaces. Ordinary oxygen is also used for melting, after which it’s ready to be used in other vessels used for making steel. However, this procedure is performed to reduce the carbon element present in it. Since there are 100 pls fasteners available in the market, it becomes slightly tough to get the best quality for which we used high-quality raw materials only

Stainless Steel Din 1.4539 Fasteners is the fundamental identity of Stainless Steel 904L Fasteners, which has a good amount of selenium and copper added with the solution of phosphorus to improve the resistance property. However, the oxidation has a player named resistance to fight in a severe condition which is held by the rest purities added in the SS 904L Fasteners. Attributes are the most important identity for which UNS NO8904 Fasteners are in huge demand, especially the power to tackle in a high-temperature environment.

Alloy 904L Fasteners are usually taken in the process of melting in electric arc furnaces. Ordinary oxygen is also used for melting, after which it’s ready to be used in other vessels used for making steel. However, this procedure is performed to reduce the carbon element present in it. Since there are 100 pls fasteners available in the market, it becomes slightly tough to get the best quality for which we used high-quality raw materials only

Forms of Stainless Steel 904L Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

Step 1: Size Detection

Step 2: GO Gauge and NO-GO Gauge Detection

Step 3: Chemical Composition Detection

Step 4: Mechanical Properties Test

Step 5: The product is carefully packaged

- Air Pollution Control — scrubbers for coal-fired power plants

- Chemical Processing — process equipment for the production of sulfuric, phosphoric, inorganic and organic acids and the production of phosphate-based fertilizers

- Metallurgical Processing — pickling equipment using sulfuric acid

- Oil and Gas Production — offshore process equipment

- Pharmaceutical Industry — process equipment

- Pulp and Paper — processing equipment

- Seawater and Brackish Water — condensers, heat exchangers and piping systems

|

Stainless Steel 904L Fasteners Equivalent Grades

|

|||||||

|

STANDARD

|

WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

|

ASME SF 594 Stainless Steel 904L Fasteners Chemical

Composition

|

|||||||||

|

Grade

|

C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.0 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 | 23.00 – 28.00 | 1.00 – 2.00 |

Related Product

JM Hardware ® Stainless Steel 310/310S Fasteners

JM Hardware ® Stainless Steel 310/310S Fasteners

JM Hardware ® is the leading company in the manufacturing of Stainless Steel 310 as well as 310S Fasteners. W...

JM Hardware ® Stainless Steel 314 (UNS S31400) W. Nr. 1.4841 Fasteners

JM Hardware ® Stainless Steel 314 (UNS S31400) W. Nr. 1.4841 Fasteners

At JM Hardware ® , we take pride in presenting our high-quality Stainless Steel 314 fasteners, engineered to ...

JM Hardware ® Stainless Steel 317/ 317L Fasteners

JM Hardware ® Stainless Steel 317/ 317L Fasteners

These fasteners are highly durable and show great tensile strength even at elevated temperatures. These fas...