INCONEL 601 SHEET - AMS 5715 - UNS N06601 ALLOY Fastener

Inconel 601 is a nickel-chromium alloy used for applications that require resistance to corrosion and heat. This nickel alloy stands out due to its resistance to high temperature oxidation, remaining highly resistant to oxidation through 2200° F. Alloy 601 develops a tightly adherent oxide scale which resists spalling even under conditions of severe thermal cycling. This nickel alloy has good high temperature strength, and retains its ductility after long service exposure. It has good resistance to aqueous corrosion, high mechanical strength, and is readily formed, machined and welded. Inconel 601’s properties make it a material of broad utility in fields like thermal processing, chemical processing, pollution control, aerospace, and power generation. However, alloy 601 is not suggested for use in strongly reducing, sulfur bearing environments.

| INCONEL | |||

| Raw Material | Unified Numbering System (UNS) | DIN EN | Common Trade Name |

| Inconel Alloy 600 | N06600 | 2.4816 | Inconel® 600 |

| Inconel 600 Specifications: UNS N06600, AMS 5540, AMS 5665, ASME SB-166, ASME SB-167, ASME SB-168, ASTM B166, ASTM B167, ASTM B168, DIN EN 2.4816 | |||

| Inconel Alloy 601 | N06601 | 2.4851 | Inconel® 601 |

| Inconel 601 Specifications: UNS N06601, AMS 5715, AMS 5870, ASME SB-167, ASME SB-168, ASTM B167, ASTM B168, DIN EN 2.4851 | |||

| Inconel Alloy 625 | N06625 | 2.4856 | Inconel® 625 |

| Inconel 625 Specifications: UNS N06625, AMS 5666, AMS 5837, ASME SB-443 Gr 1, ASME SB-446 Gr 1, ASTM B443 Gr 1, ASTM B446 Gr 1, ISO 15156-3, NACE MR0175-3, DIN EN 2.4856 | |||

| Inconel Alloy 718 | N07718 | 2.4668 | Inconel® 718 |

| Inconel 718 Specifications: UNS N07718, AMS 5596, AMS 5662, AMS 5663, AMS 5832, ASME Case 2222-1, ASME SFA 5.14, ASTM B637, ASTM B670, GE B50TF14, GE B50TF15, DIN EN 2.4668 | |||

Forms of INCONEL 601 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

Step 1: Size Detection

Step 2: GO Gauge and NO-GO Gauge Detection

Step 3: Chemical Composition Detection

Step 4: Mechanical Properties Test

Step 5: The product is carefully packaged

1. Fire protection systems, seawater purification systems, hydraulic and perfusion piping systems in marine engineering.

2. Bleaching tank in cellulose pulp production.

3. Polished bars in corrosive oil wells.

4. Hose system in marine engineering.

5. Pipelines, joints, gas flow systems, etc. in acid gas production.

6. Components in the flue gas desulfurization system.

7. Evaporators, heat exchangers, filters, mixers, etc. in phosphoric acid production.

8. Sulfuric acid separation and condensation system.

2. Bleaching tank in cellulose pulp production.

3. Polished bars in corrosive oil wells.

4. Hose system in marine engineering.

5. Pipelines, joints, gas flow systems, etc. in acid gas production.

6. Components in the flue gas desulfurization system.

7. Evaporators, heat exchangers, filters, mixers, etc. in phosphoric acid production.

8. Sulfuric acid separation and condensation system.

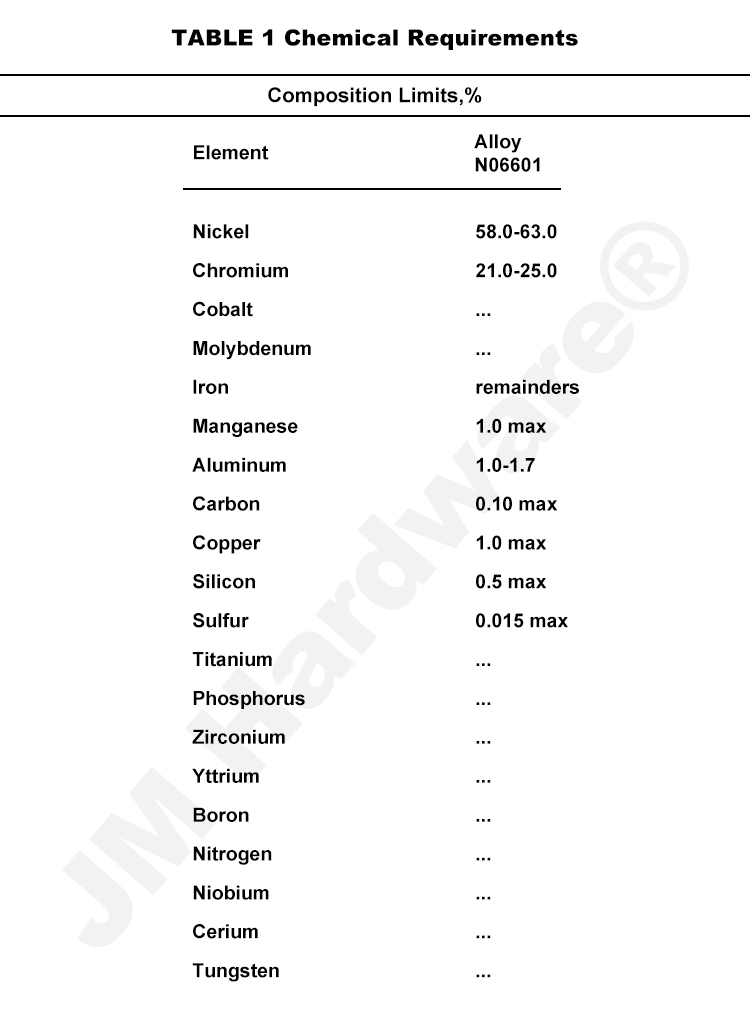

The chemical composition of INCONEL 601 fasteners is as follows

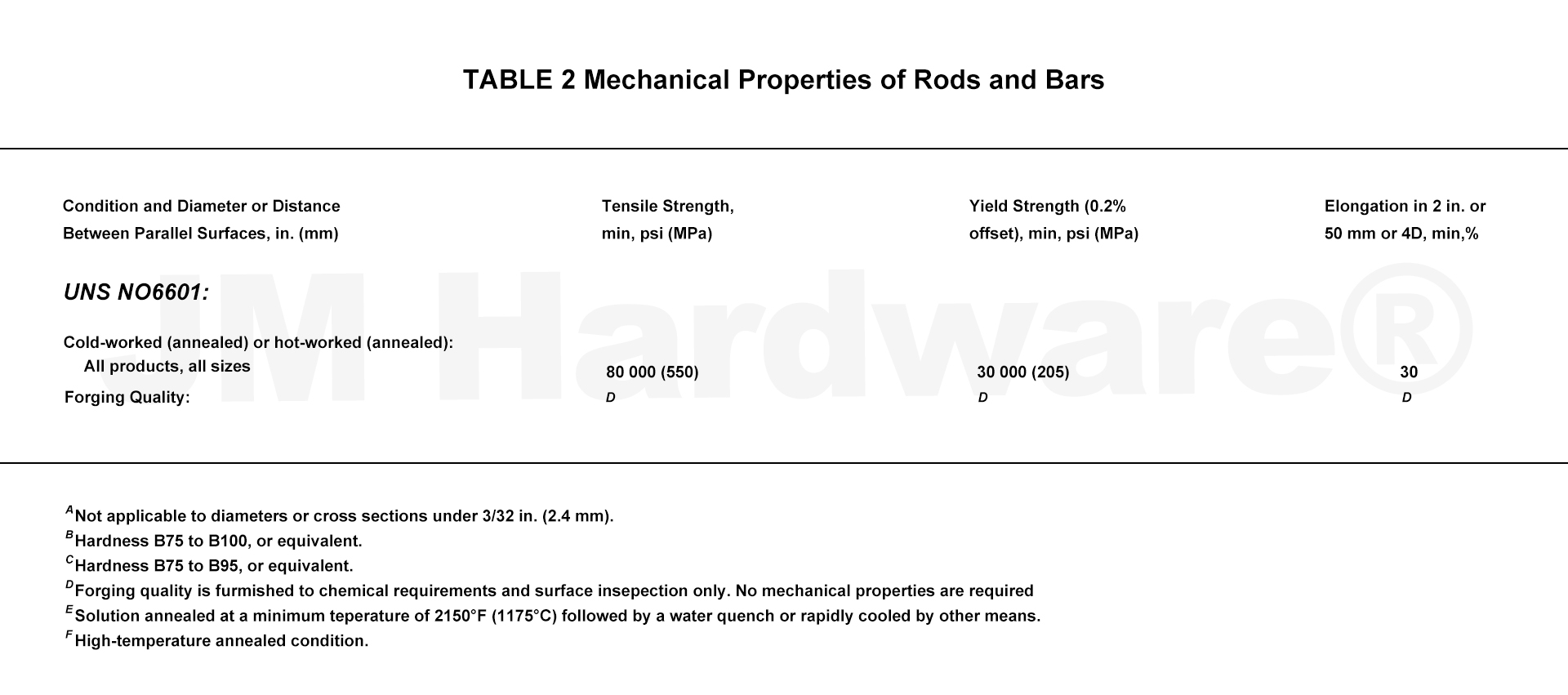

The mechanical properties of INCONEL 601 fasteners are as follows

Related Product

INCONEL 600 SHEET - AMS 5540 - UNS N06600 ALLOY Fastener

INCONEL 600 SHEET - AMS 5540 - UNS N06600 ALLOY Fastener

Inconel® 600 (AMS 5540) is a nickel-chromium alloy designed for use at cryogenic ...

INCONEL 625 SHEET - AMS 5599 - UNS N06625 ALLOY Fastener

INCONEL 625 SHEET - AMS 5599 - UNS N06625 ALLOY Fastener

Inconel 625 is a corrosion and oxidation resistant nickel alloy that is used both for...

Nimonic 80A SHEET- UNS N07080/ ASTM B637/ WS 2.4631/ WS 2.4952/ AFNOR NC 20TA ALLOY Fastener

Nimonic 80A SHEET- UNS N07080/ ASTM B637/ WS 2.4631/ WS 2.4952/ AFNOR NC 20TA ALLOY Fastener

We use advanced manufacturing processes and state-of-the-art equipment to produce fasten...

INCONEL 718 SHEET - AMS 5596 - UNS N07718 ALLOY Fastener

INCONEL 718 SHEET - AMS 5596 - UNS N07718 ALLOY Fastener

Inconel 718 is a nickel-chromium-molybdenum alloy designed to resist a wide range of ...

Special Alloy Fastener

- Titanium & Titanium Alloy

- Hastelloy Alloy

- Monel Alloy

-

Inconel Alloy

- INCONEL 600 SHEET - AMS 5540 - UNS N06600 ALLOY Fastener

- INCONEL 601 SHEET - AMS 5715 - UNS N06601 ALLOY Fastener

- INCONEL 625 SHEET - AMS 5599 - UNS N06625 ALLOY Fastener

- Nimonic 80A SHEET- UNS N07080/ ASTM B637/ WS 2.4631/ WS 2.4952/ AFNOR NC 20TA ALLOY Fastener

- INCONEL 718 SHEET - AMS 5596 - UNS N07718 ALLOY Fastener

- INCONEL 725 SHEET - UNS N07725 ALLOY Fastener

- INCONEL X750 SHEET - AMS 5567 - UNS N07750 ALLOY Fastener

- INCONEL 617 SHEET- UNS N06617/ W.Nr. 2.4663a ALLOY Fastener

- Nickel Alloy

- Duplex Stainless Steel

- High temperature Alloy steel

- Stainless Steel