Nickel 200 is a 99.6% pure nickel alloy and one of the toughest metals in existence. It exhibits excellent mechanical properties and high thermal and electrical conductivity. Additionally, Nickel 200’s beneficial properties and its chemical composition make it easily fabricable and highly resistant to corrosive environments.

As an ISO 9001 certified supplier of industrial metals to the global aerospace, oil and gas, power generation, petrochemical, bio-medical, pharmaceutical, and other high tech manufacturing industries, JM Hardware® is your premier source for nickel alloy UNS N02200. We supply Nickel 200 alloy to manufacturers and distributors in the United States and to over 60 countries throughout the world.

Forms of Nickel 200 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Nickel 200 Advantages

Nickel 200 is a 99.6% pure nickel alloy, is useful in any environment below 600º F. It is highly resistant to corrosion by neutral and alkaline salt solutions. Nickel alloy 200 also has low corrosion rates in neutral and distilled water. This nickel alloy can be hot formed to any shape and formed cold by all methods. Additional benefits include:- Excellent mechanical properties

- Low gas content

- Low vapor pressure

- Magnetic properties

- High thermal and electrical conductivity

Nickel 200 Applications

Nickel alloy 200 has many different industrial applications, some of which include:- Electronic components

- Electrical components

- Wires for heating elements

- Battery connections/terminals

- Chemical processing

- Aerospace components

- Food processing

- Synthetic fiber processing

| Specifications | |

| Form | Standard |

| Metal Type | UNS N02200 |

| Bar | ASTM B160 Din 17752 BS 3076 |

| Wire | |

| Sheet | ASTM B162 Din 17750 BS 3072 |

| Plate | ASTM B162 Din 17750 BS 3072 |

| Tube | ASTM B622 ASTM B161 ASTM B163 Din 17740 BS 3074 |

| Pipe | ASTM B622 ASTM B161 Din 17740 BS 3074 |

| Fitting | ASTM B366 |

| Forging | ASTM B564 |

| Weld Wire | ERNi-CI |

| Weld Electrode | ENi-1 |

| NA 11 | All forms |

| Din | 2.4066 All forms |

|

MACHINING

DATA

|

|

| Carbide tools are suggested | |

| for rates better than 50% of Type 304. | |

| Machining Type | Suggested starting rates are: |

| Single Point turning : | Roughing - 0.15" depth, 0.015"/rev feed -175 SFM |

| Finishing - 0.025" depth, 0.007"/rev feed - 200 SFM | |

| Drilling : | 1/4" Dia hole - 0.004"/rev feed - 60 SFM |

| 1/2" Dia hole - 0.007"/rev feed - 60 SFM | |

| 3/4" Dia hole - 0.010"/rev feed - 60 SFM | |

| Reaming : | Feed - same as drilling - 100 SFM |

| Side and Slot Milling : | Roughing - 0.25" depth - 0.007"/tooth feed - 125SFM |

| Finishing - 0.050" depth - 0.009"/tooth feed - 140SFM | |

| These rates are for carbide tools, | |

| Type C-2 for roughing, drilling and reaming. | |

| Type C-3 for finishing. | |

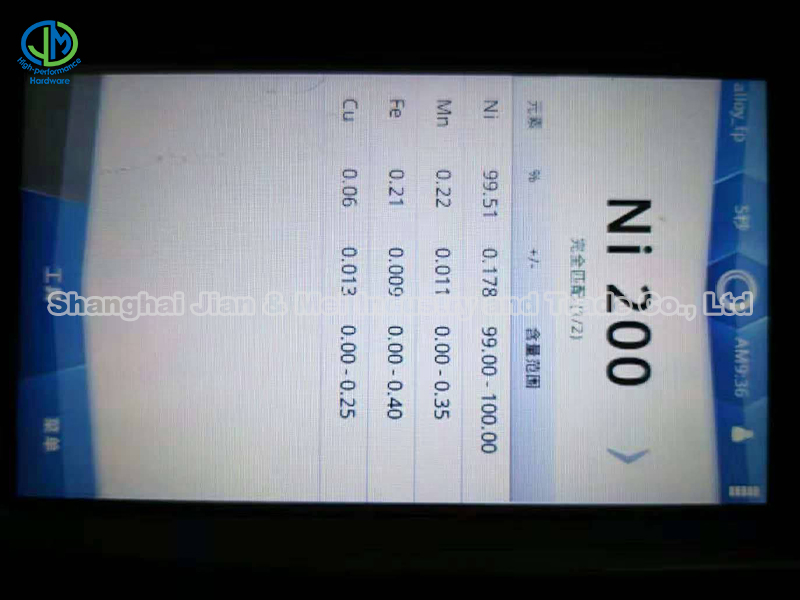

| Chemical Requirements | |||||||

| Ni | C | Mn | Cu | S | Si | Fe | |

| Max | 0.15 | 0.35 | 0.25 | 0.01 | 0.35 | 0.4 | |

| Min | 99 | ||||||

Nickel 201 SHEET- UNS N02201 ALLOY Fastener

Nickel 201 SHEET- UNS N02201 ALLOY Fastener