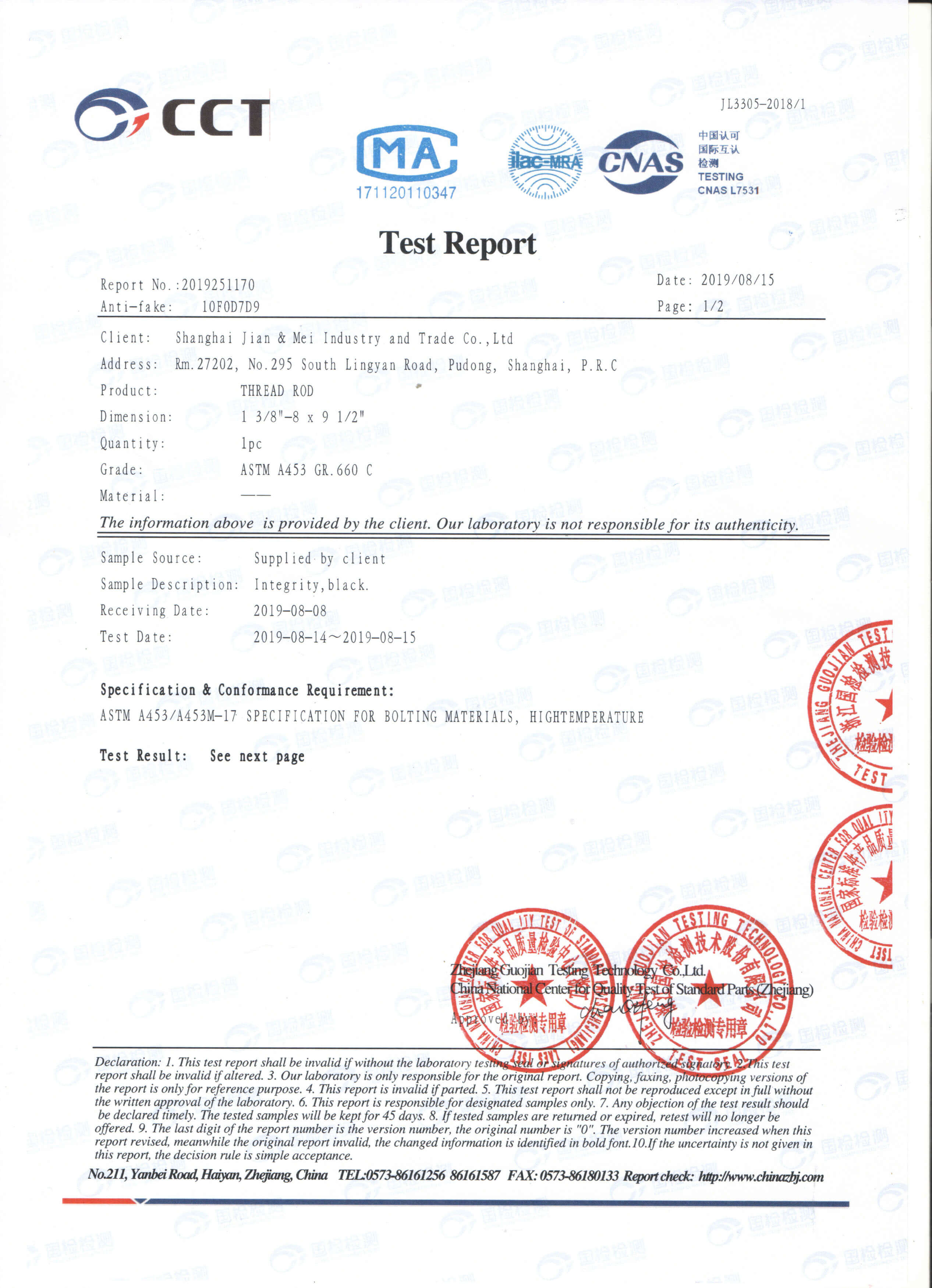

ASTM A453

The specification for ASTM A453 covers five grades of bolting with twelve classes of yield strength ranging from 50 to 120 ksi (345 to 827 MPa) and is commonly used in high temperature environment such as fasteners for pressure vessels and valve flanges. The material included in ASTM A453 requires special processing and is not intended for general purpose applications.

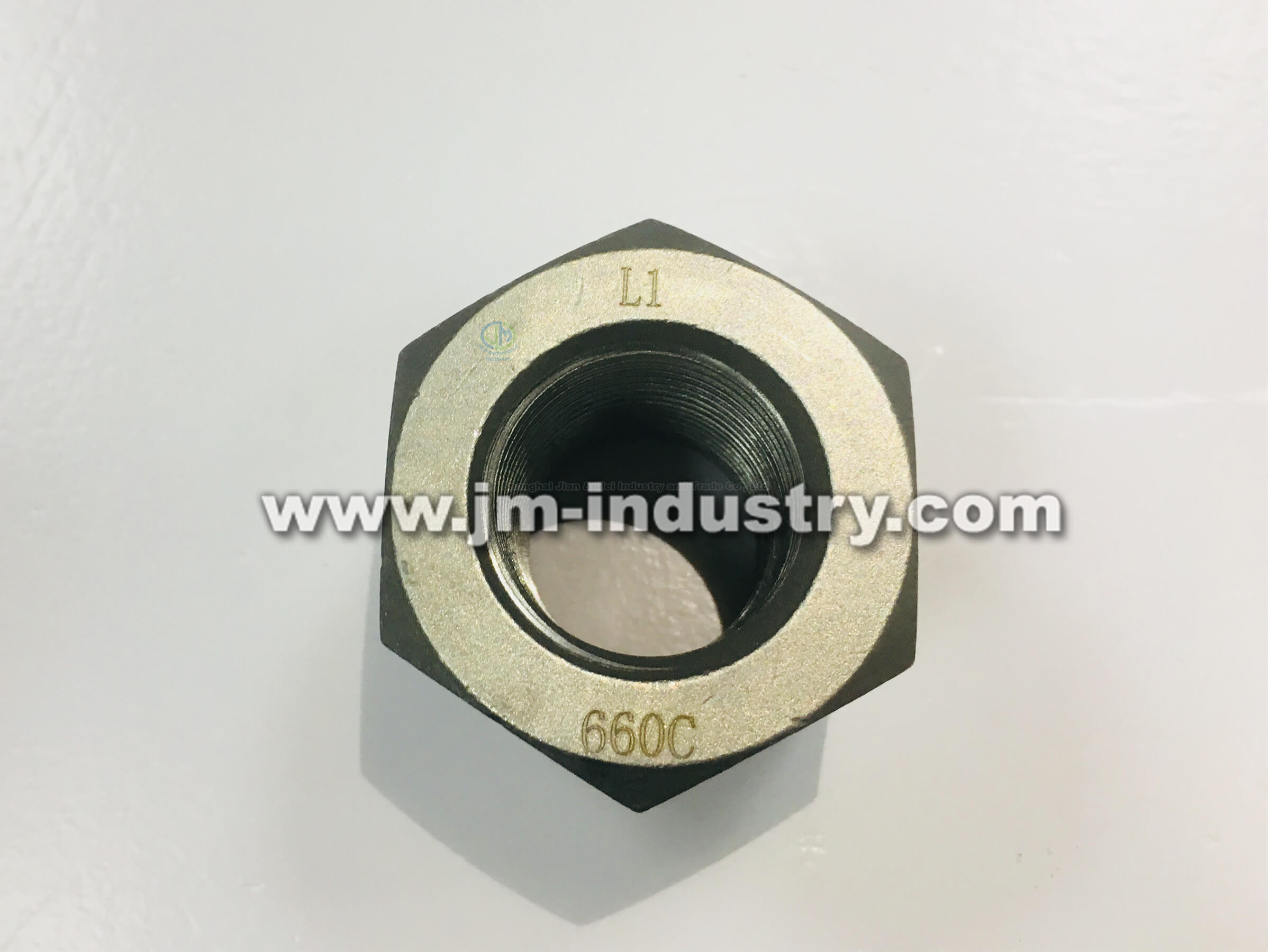

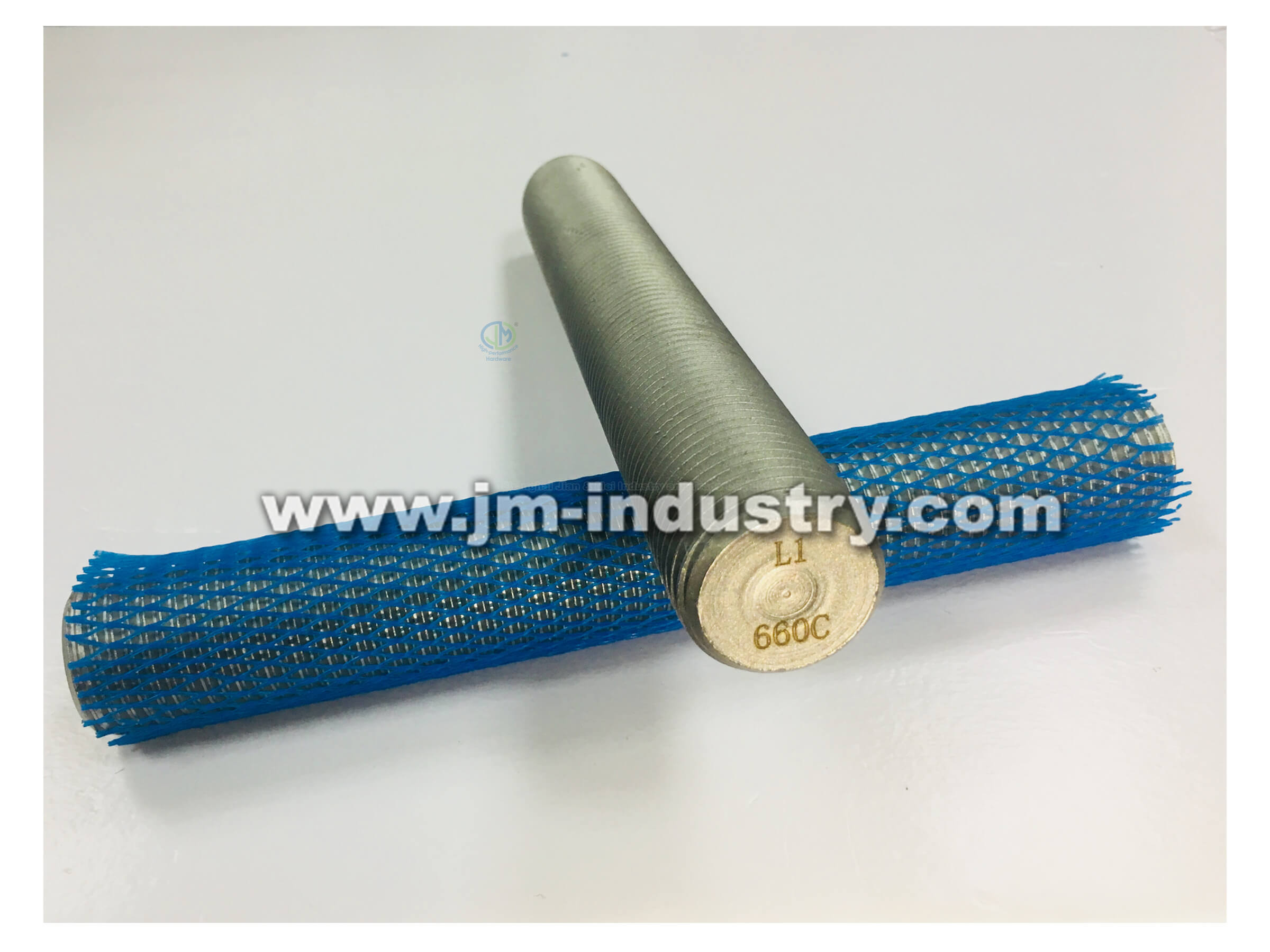

Forms of ASTM A453 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| STUD BOLT | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Material Chemical Composition Requirements

| Grade | Grade 660 | Grade 651 | Grade 662 | Grade 665 | Grade 668 |

| UNS Number | S66286 | S63198 | S66220 | S66545 | S66285 |

| ELEMENT | % | % | % | % | % |

| Carbon | 0.08 max | 0.28-0.35 | 0.08 max | 0.08 max | 0.08 max |

| Manganese | 2.00 max | 0.75-1.5 | 0.40-1.00 | 1.25-2.00 | 2.00 max |

| Phosphorus, max | 0.040 max | 0.040 max | 0.040 max | 0.040 max | 0.040 max |

| Sulfur, max | 0.030 max | 0.030 max | 0.030 max | 0.030 max | 0.030 max |

| Silicon | 1.00 max | 0.30-0.80 | 0.40-1.00 | 0.1-0.80 | 1.00 max |

| Nickel | 24.0-27.0 | 8.0-11.0 | 24.0-28.0 | 24.0-28.0 | 17.5-21.5 |

| Chromium | 13.5-16.0 | 18.0-21.0 | 12.0-15.0 | 12.0-15.0 | 13.5-16.0 |

| Molybdenum | 1.00-1.50 | 1.00-1.75 | 2.0-3.50 | 1.25-2.25 | 1.50 max |

| Tungsten | ... | 1.00-1.75 | ... | ... | ... |

| Titanium | 1.9-2.35 | 0.1-0.35 | 1.80-2.10 | 2.70-3.30 | 2.20-2.80 |

| Columbium * | ... | 0.25-0.6 | ... | ... | ... |

| Aluminum | 0.35 max | 0.35 max | 0.25 max | 0.50 max | |

| Vanadium | 0.10-0.50 | ... | ... | 0.50 max | |

| Boron | 0.001-0.010 | 0.001-0.010 | 0.01-0.07 | 0.001-0.010 | |

| Copper | 0.50 max | 0.50 max | 0.25 max | ... |

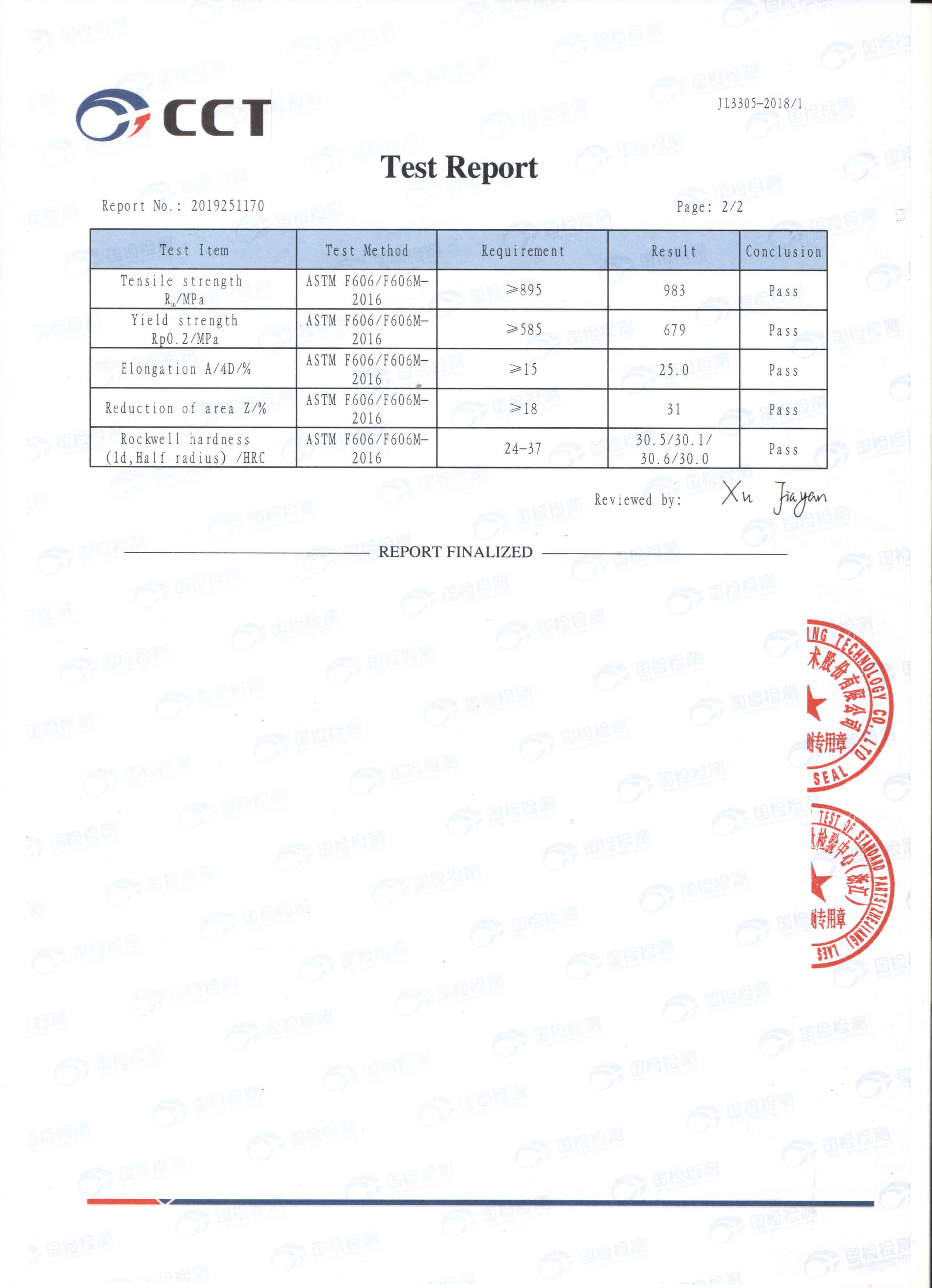

Mechanical Properties Requirements

| Size | Class | Tensile, Mpa | Yield, Mpa | Elong. %, min | RA %, min | Brinell Hardness | Approximate Rockwell Hardness B and C |

| Grade 660 | A, B , & C | 895 min | 585 min | 15 | 18 | 248-341 | 24-37 HRC |

| D | 895 min | 725 min | 15 | 18 | 248-321 | 24-35 HRC | |

| Grade 651 | A | 690 min | 485 min (D<=3" ) | 18 | 35 | 217-277 | 95HRB-29HRC |

| 415 min (D>3" ) | |||||||

| B | 655 min | 415 min (D<=3" ) | 18 | 35 | 212-269 | 93HRB-28HRC | |

| 345 min (D>3" ) | |||||||

| Grade 662 | A | 895 min | 585 min | 15 | 18 | 248-321 | 24-35 HRC |

| B | 860 min | 550 min | 15 | 18 | 248-321 | 24-35 HRC | |

| Grade 665 | A | 1170 min | 830 min | 12 | 15 | 311-388 | 32-41 HRC |

| B | 1070 min | 830 min | 12 | 15 | 311-388 | 32-41 HRC | |

| Grade 668 | A & B | 895 min | 585 min | 15 | 18 | 248-341 | 24-37 HRC |

Heat Treatment Requirements

| Grade | Class | Solutiona Treatment | Hardening Treatment |

| 660 | A | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

| B | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool | |

| C | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and oil quench | 1425 +/- 25 °F [775 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool | |

| D | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench OR | 1325 +/- 25 °F [720 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool | |

| 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | if neccessary to achieve properties, second age : 1200 +/- 25 °F [650 +/- 14 °C] hold 16h, air cool | ||

| 651 | A | hot-cold worked at 1200 °F[650] min with 15% min reduction in cross sectional area, stress-relief anneal at 1200 °F [650 °C] min or 4h, min | |

| B | hot-cold worked at 1200 °F[650] min with 15% min reduction in cross sectional area, stress-relief anneal at 1350 °F [730 °C] min or 4h, min | ||

| 662 | A | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool |

| B | 1950 +/- 25 °F [1065 +/-14 °C], hold 2 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool | |

| 665 | A | 1800 +/- 25 °F [980 +/-14 °C], hold 3 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool |

| B | 2000 +/- 25 °F [1095 +/-14 °C], hold 3 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool | |

| 668 | A | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

| B | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

Stree Rupture Requirements

| Grade | Class | Test Temperature | Stress, Min | Time to Rupture | Elongation | |

| Deg F [ Deg C ] | Ksi | Mpa | Min, h* | Min % | ||

| 660 | A, B & C | 1200 [650] | 56 | 385 | 100 | 5 |

| 651 | A & B | 1200 [650] | 40 | 275 | 100 | 5 |

| 662 | A & B | 1200 [650] | 55 | 380 | 100 | 5 |

| 665 | A | 1200 [650] | 75 | 515 | 100 | 3 |

| B | 1200 [650] | 70 | 485 | 100 | 5 | |

Special Alloy Fastener