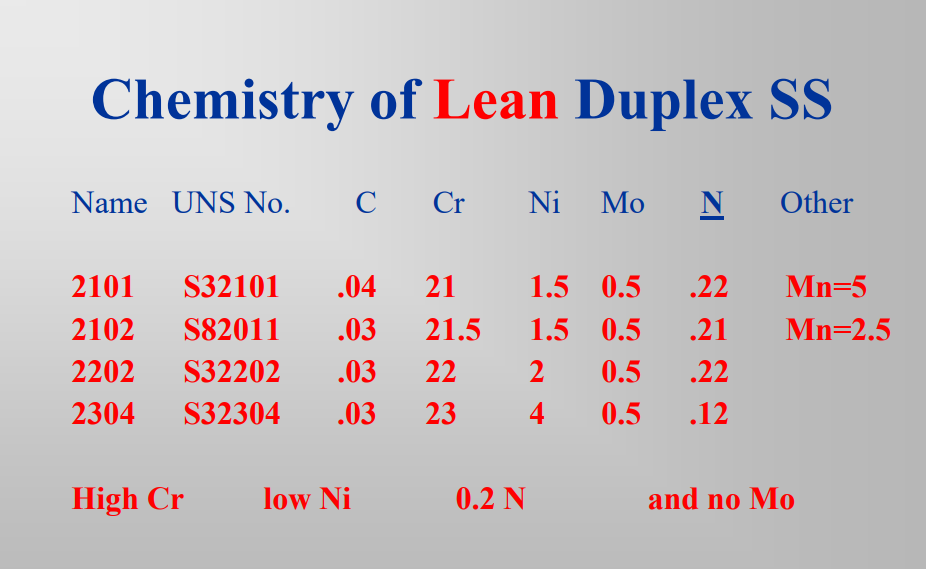

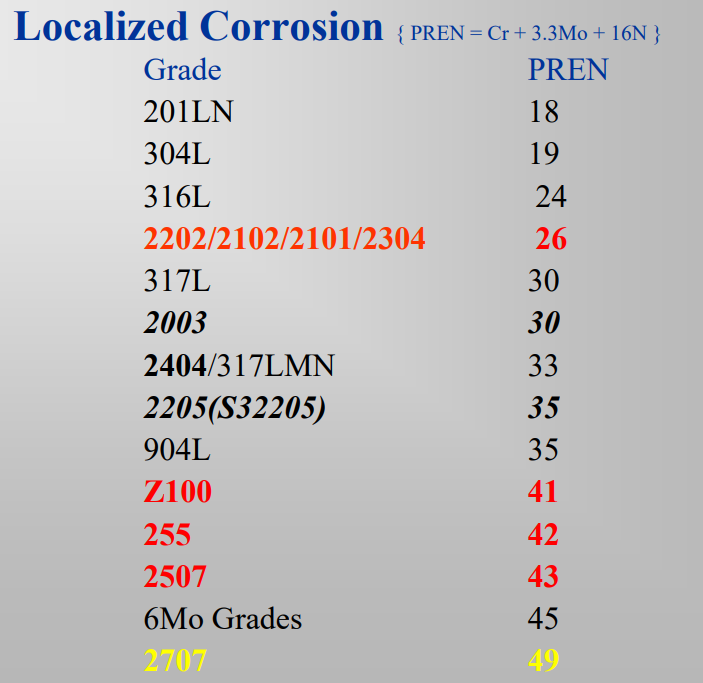

Lean Duplex Stainless Steel (PREN range: 22–27)- UNS No. S32101, S82011, S32202, S32304

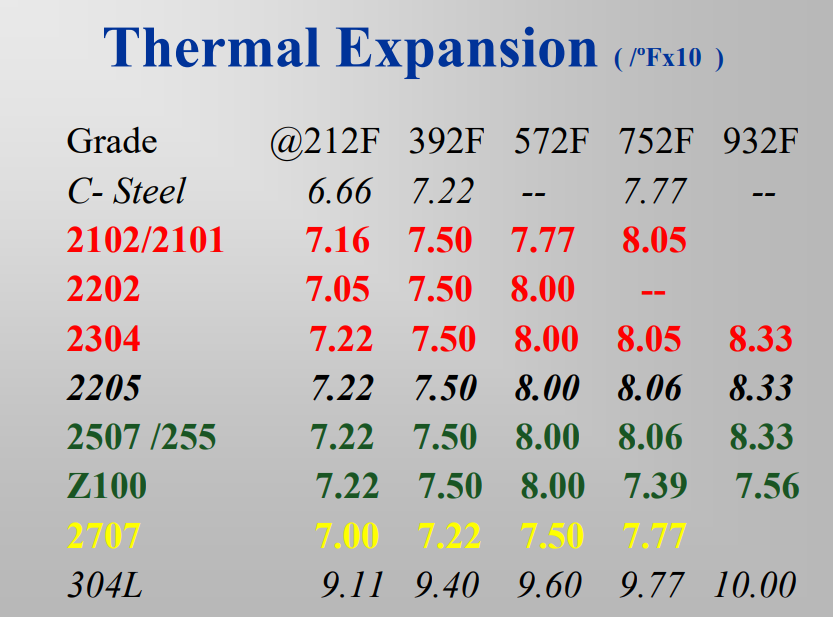

Typically grade EN 1.4362, have been developed more recently for less demanding applications, particularly in the building and construction industry. Their corrosion resistance is closer to that of the standard austenitic grade EN 1.4401 (with a plus on resistance to stress corrosion cracking) and their mechanical properties are higher. This can be a great advantage when strength is important. This is the case in bridges, pressure vessels or tie bars.

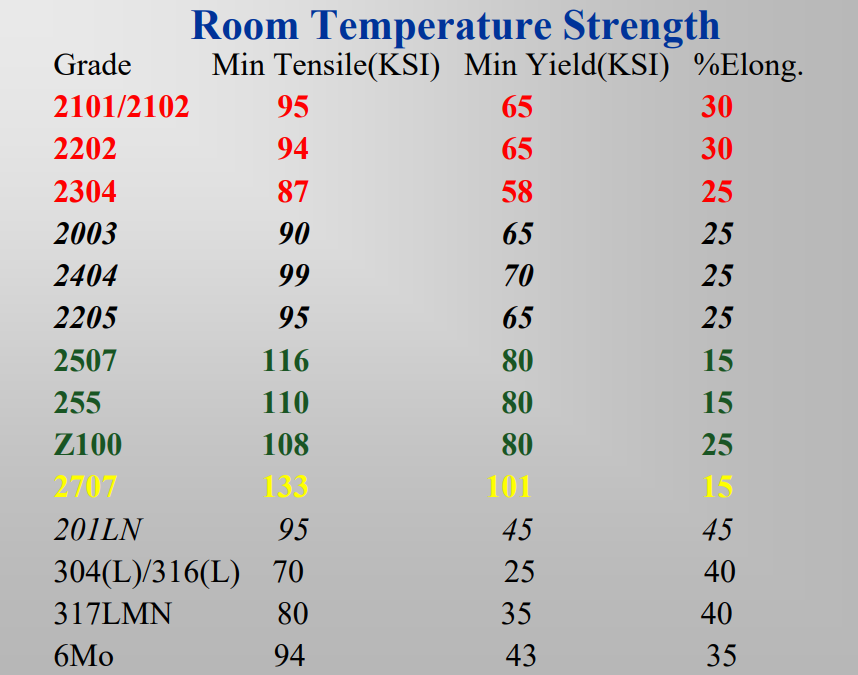

It possesses properties such as high mechanical strength, similar to that of other duplex steels, and good corrosion resistance. Compared to 300 series stainless steels, Lean duplex stainless provides superior strength and greater chloride stress corrosion cracking resistance.

The use of manganese ensures proper ferrite-austenite phase balance, while allowing a reduction in nickel content. As a result, Lean duplex stainless is priced competitively with 304L and 316L stainless steels. Due to its relatively low alloying content, it is less prone to precipitation of intermetallic phases than other duplex steels.

The use of manganese ensures proper ferrite-austenite phase balance, while allowing a reduction in nickel content. As a result, Lean duplex stainless is priced competitively with 304L and 316L stainless steels. Due to its relatively low alloying content, it is less prone to precipitation of intermetallic phases than other duplex steels.

| Lean Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| 2101 | S32101 | 1.4162 | 0,04 | 21,0-22,0 | 1,35-1,7 | 0,1 – 0,8 | 0,20-0,25 | 4,0-6,0 | 0,1-0,8 | – | 26 | |

| F66 | 2202 | S32202 | 1.4062 | 0,03 | 21,5-24,0 | 1,0-2,8 | 0,45 | 0,18-0,26 | 2,0 | – | 26 | |

| F68 | 2304 | S32304 | 1.4362 | 0,03 | 21,5-24,5 | 3,0-5,5 | 0,05-0,6 | 0,05-0,20 | 2,5 | 0,05-0,60 | – | 26 |

| 2102 | S82011 | 0,03 | 20.5-23.5 | 1.00-2.00 | 0,1 – 1.00 | 0.15-0.27 | 2.00-3.00 | 0.5 | – | 26 | ||

| Standard Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| F51 | 2205 | S31803 | 1.4462 | 0,03 | 21,0-23,0 | 4,5-6,5 | 2,5-3,5 | 0,08-0,20 | 2,0 | – | – | 33 |

| F60 | 2205 | S32205 | 1.4462 | 0,03 | 22,0-23,0 | 4,5-6,5 | 3,0-3,5 | 0,14-0,20 | 2,0 | – | – | 35 |

| 2003 | S32003 | 1.4662 | 0,03 | 19.5-22.5 | 3.0-4.0 | 1.5-2.0 | 0.14-0.2 | 2,0 | – | – | 30 | |

| 2404 | S82441 | 1.4662 | 0,03 | 23.0-25.0 | 3.0-4.5 | 1.00-2.00 | 0.20-0.30 | 2.5-4.0 | 0.10-0.80 | – | 33 | |

| Super Duplex | ||||||||||||

| ID | Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* |

| F59 | S32520 | 1.4507 | 0,03 | 24,0-26,0 | 5,5-8,0 | 3,0-4,0 | 0,20-0,35 | 1,5 | 0,5-2,0 | – | >40 | |

| F61 | 255 | S32550 | 1.4507 | 0,04 | 24,0-27,0 | 4,5-6,5 | 2,9-3,9 | 0,10-0,25 | 1,5 | 1,5-2,5 | – | >40 |

| F53 | 2507 | S32750 | 1.441 | 0,03 | 24,0-26,0 | 6,0-8,0 | 3,0-5,0 | 0,24-0,32 | 1,2 | 0,50 | – | 43 |

| F55 | Z100 | S32760 | 1.4501 | 0,03 | 24,0-26,0 | 6,0-8,0 | 3,0-4,0 | 0,20-0,30 | 1,0 | 0,5-1,0 | 0,5-1,0 | 42 |

| Hyper Duplex | ||||||||||||

| Name | ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn max. | Cu | W | PRE* | |

| 2707 | S32707 | – | 0,03 | 26,0-29,0 | 5,5-9,5 | 4,0-5,0 | 0,30-0,50 | 1,5 | 1,00 | – | 49 | |

| 3207 | S33207 | – | 0,03 | 29,0-33,0 | 6,0-9,0 | 3,0-5,0 | 0,40-0,60 | 1,5 | 1,00 | – | 50 | |

| Austenitic Grades | ||||||||||||

| ASTM | EN-Nr. | C max. | Cr | Ni | Mo | N | Mn | Cu | W | PRE* | ||

| 304L | 1.4307 | 0,03 | 17,5-19,5 | 8,0-10,5 | – | 0,11 | – | – | – | 18 | ||

| 316L | 1.4404 | 0,03 | 16,5-18,5 | 10,0-13,0 | 2,0-2,5 | 0,10 | – | – | – | 24 | ||

| 904L | 1.4539 | 0,02 | 19,0-21,0 | 24,0-26,0 | 4,0-5,0 | 0,15 | – | 1,20 | – | 34 | ||

| S31254 | 1.4547 | 0,2 | 19,5-20,5 | 17,5-18,5 | 6,0-7,0 | 0,18-0,25 | – | 0,5-1,0 | – | 43 | ||

Forms of Lean Duplex SS Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6921 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

Step 1: Size Detection

Step 2: GO Gauge and NO-GO Gauge Detection

Step 3: Chemical Composition Detection

Step 4: Mechanical Properties Test

Step 5: The product is carefully packaged

Duplex stainless steels are usually selected for their high mechanical properties and good to very high corrosion resistance (particularly to stress corrosion cracking).

Oil and Gas:

a wide range of equipment: flowlines, manifolds, risers, pumps, valves, etc.

Pulp and Paper:

digesters, pressure vessels, liquor tanks, etc.

Chemical engineering:

pressure vessels, heat exchangers, condensers, distillation columns, agitators, marine chemical tankers, etc.

Water:

desalination plants, large tanks for water storage, waste water treatment

renewable energy: Biogas tanks

Mobility: tramcars and bus frames, tank trucks, iron ore wagons

Engineering: pumps, valves, fittings, springs, etc.

Oil and Gas:

a wide range of equipment: flowlines, manifolds, risers, pumps, valves, etc.

Pulp and Paper:

digesters, pressure vessels, liquor tanks, etc.

Chemical engineering:

pressure vessels, heat exchangers, condensers, distillation columns, agitators, marine chemical tankers, etc.

Water:

desalination plants, large tanks for water storage, waste water treatment

renewable energy: Biogas tanks

Mobility: tramcars and bus frames, tank trucks, iron ore wagons

Engineering: pumps, valves, fittings, springs, etc.

Related Product

Standard Duplex Stainless Steel(PREN range: 28–38) - UNS No. S32003,S82441,S31803,S32205

Standard Duplex Stainless Steel(PREN range: 28–38) - UNS No. S32003,S82441,S31803,S32205

Standard Duplex Stainless Steel: Chromium content between 19.5 and 23 percent, nickel content between 3 and 6.5...

Super Duplex Stainless Steel(PREN range: 38–45) - UNS No. S32750,S32760,S32550,S32520

Super Duplex Stainless Steel(PREN range: 38–45) - UNS No. S32750,S32760,S32550,S32520

Typically grade EN 1.4410 up to so-called hyper duplex grades (PREN: >45) developed later to meet specific d...

Hyper Duplex Stainless Steel(PREN range: 49-50) - UNS No. S32707,S33207

Hyper Duplex Stainless Steel(PREN range: 49-50) - UNS No. S32707,S33207

Hyper Duplex Stainless Steel: is an even more advanced version with a content of chromium of up to 33 percent, ...

Special Alloy Fastener

- Titanium & Titanium Alloy

- Hastelloy Alloy

- Monel Alloy

- Inconel Alloy

- Nickel Alloy

-

Duplex Stainless Steel

- Lean Duplex Stainless Steel (PREN range: 22–27)- UNS No. S32101, S82011, S32202, S32304

- Standard Duplex Stainless Steel(PREN range: 28–38) - UNS No. S32003,S82441,S31803,S32205

- Super Duplex Stainless Steel(PREN range: 38–45) - UNS No. S32750,S32760,S32550,S32520

- Hyper Duplex Stainless Steel(PREN range: 49-50) - UNS No. S32707,S33207

- Incoloy Alloy Fastener

- High temperature Alloy steel

- Stainless Steel