Nickel Alloy 500/ Monel 500 Bolts and Nuts and Nuts

Monel K500 bolts are comprised of a nickel alloy that combines the outstanding corrosion resistance of Monel 400 with increased strength and hardness. These additional attributes of Monel K500 bolts are a result of an age hardening process where aluminum and titanium are added to the nickel-copper base and then precipitated throughout the matrix. This process gives K500 approximately 3 times the yield strength ( 110ksi vs 45ksi) and double the tensile strength (160ksi vs 83ksi) when compared 400. Monel K500 bolts will retain their strength to 1200°F and even retain their ductility as low as -400°F.

Corrosion Resistance

Monel K500 bolts offer a unique combination of high strength with similar corrosion resistance to Monel 400 and improved resistance to a sour-gas environments. Stronger than 400, alloy K500 even retains this strength in corrosive conditions, resisting both pure and salt water, as well as non-oxidizing mineral acids, salts, alkalis, and sour gas. The exception being that Monel K500 bolts can be more prone to stress-corrosion cracking in some environments than Monel 400. In addition, stagnant or slow-moving sea water can cause fouling which is followed by pitting, but pitting typically slows after initial attack.

Outstanding Low Temperature Capabilities

Monel K500 bolts are virtually non-magnetic and spark resistant, even at temperatures down to -200°F. Though in some applications, Monel K500 can develop a magnetic layer during processing when aluminum and copper are selectively oxidized during heating, leaving a magnetic nickel-rich film on the outside. This can be corrected by pickling or bright dipping in acid, which will remove any magnetic film and restore it to a non-magnetic condition. In addition, Monel K500 bolts also offer outstanding low temperature properties. When utilized at subzero temperatures, these bolts actually increase their tensile and yield strengths, while ductility and toughness are virtually unchanged. Hence, Monel K500 bolts are utilized in many cryogenic applications.

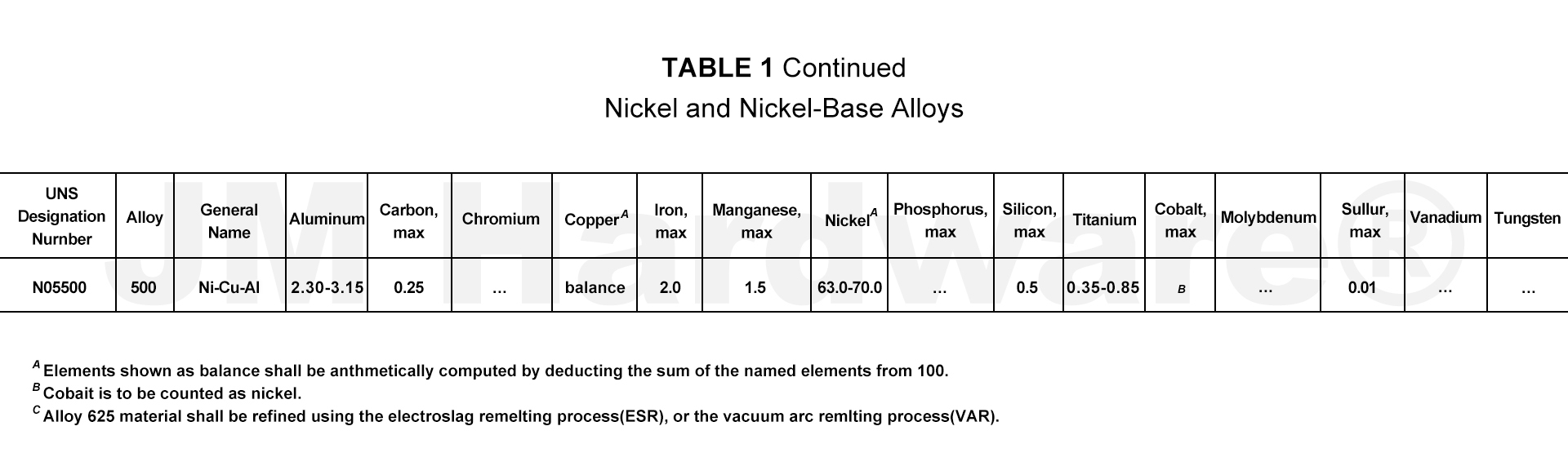

The chemical composition of Monel K500 fasteners is as follows

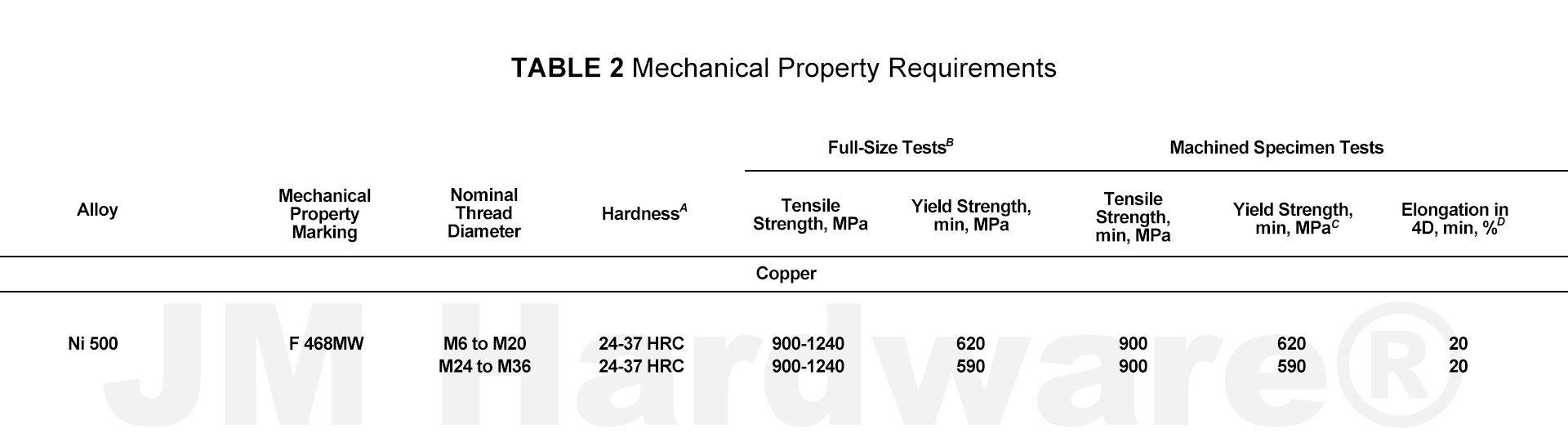

The mechanical properties of Monel K500 fasteners are as follows

Different Countries Steel No. Chart

| Alloy Name | Trade Name | UNS No. | British Specs | American Specs | German Specs |

| Alloy K500 | Monel K500 | UNS N05500 | BS 3072 | AMS 4676 Bar and Forgings | WS 2.4375 |

| BS 3073 | QQ-N-286 | ||||

| BS 3074 | |||||

| BS 3075 | |||||

| BS 3076 | |||||

| NA18 |

Forms of Monel K500 Fastener Available at JM-INDUSTRY

| Product name | Standard No. | Size | |

| BOLT | HEX HEAD BOLT | ANSI/ASME B18.2.1, DIN933, DIN931 | 1/4”-4”, M5-M100 |

| SOCKET CAP SCREW | ANSI/ASME B18.3, DIN912, DIN7991, DIN913/916 | 1/4”-4”, M5-M100 | |

| FLANGE BOLT | ANSI/ASME B18.2.3.4M-2001, DIN 6923 | 1/2”-4”, M10-M100 | |

| EYE BOLT | ANSI/ASME, DIN standard | 1/2”-4”, M10-M100 | |

| OTHER BOLT | U BOLT, T BOLT, J BOLT, SQURE HEAD BOLT, SHOULDER BOLT, AND NON-STANDARD BOLT ACCORDING TO CUSTOMER NEEDS. | ||

| STUD | THREADED ROD/BAR | ANSI/ASME, DIN975/DIN976 | 3/8”-4”, M5-M100 |

| DOUBLE ENDS STUDS | ANSI/ASME, DIN STANDARD | 3/8”-4”, M5-M100 | |

| NUT | HEX NUT | ANSI/ASME B18.2.2, DIN934 | 1/4”-4”, M5-M100 |

| HEAVY HEX NUT | ANSI/ASME B18.2.2, DIN standard | 1/2”-4”, M12-M100 | |

| NYLON LOCK NUT | ANSI/ASME B18.16.6-2008, DIN 985,DIN982 | 1/2”-4”, M12-M100 | |

| FLANGE NUT | ANSI/ASME, DIN6923 | 1/2”-4”, M12-M100 | |

| COUPLING NUT/LONG NUT | ANSI/ASME, DIN STANDARD | 1/2”-4”, M12-M100 | |

| SQUARE NUT | ANSI/ASME, DIN 557 | 1/2”-4”, M12-M100 | |

| HEX DOOMD CAP NUT | ANSI/ASME, DIN1587 | 1/2”-4”, M12-M100 | |

| WING NUT | ANSI/ASME, DIN315 | 1/2”-4”, M12-M100 | |

| WASHER | FLAT WASHER | ANSI/ASME B18.22.1, DIN125 | 3/8”-4”, M6-M100 |

| SPRING WASHER | ANSI/ASME B18.21.1, DIN127 | 3/8”-4”, M6-M100 |

Testing before shipping

Monel 400 SHEET - UNS N04400 ALLOY Fastener

Monel 400 SHEET - UNS N04400 ALLOY Fastener

Monel R-405 SHEET - UNS N04405 ALLOY Fastener

Monel R-405 SHEET - UNS N04405 ALLOY Fastener