-

Whatsapp: +86-13681923533

-

email: jminfo@jm-industry.com

How to Detect Surface Cracks in Fasteners: 4 Critical NDT Methods Explained

Jul 31, 2025

Why Crack Detection Matters

Surface cracks in bolts, screws, and studs reduce load capacity by up to 90% and cause 80% of fastener failures in critical applications. This guide covers industry-proven NDT (Non-Destructive Testing) methods to identify defects before they compromise structural integrity.

The 4 Core Crack Detection Methods

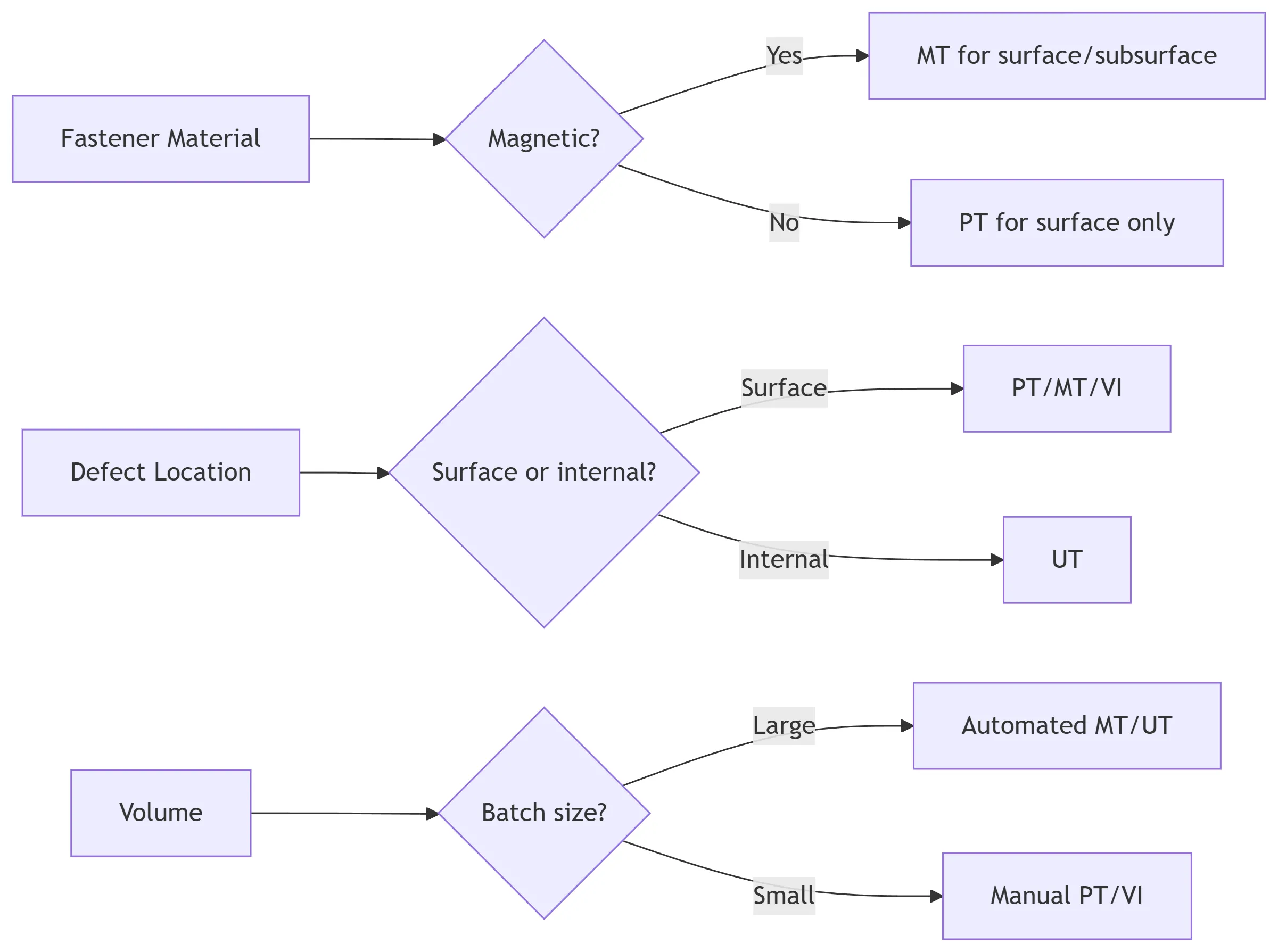

(Selection Depends on Material & Defect Type)

| Method | Best For | Detection Limit | Speed | Cost |

|---|---|---|---|---|

| Magnetic Particle (MT) | Ferromagnetic fasteners | 0.1 μm | ★★★★★ | $$ |

| Liquid Penetrant (PT) | Non-magnetic metals | 0.5 μm | ★★★☆☆ | $ |

| Ultrasonic (UT) | Internal/sub-surface defects | 0.1 mm | ★★☆☆☆ | $$$$ |

| Visual Inspection (VI) | Quick field screening | 0.1 mm | ★★★★★ | $ |

1. Magnetic Particle Testing (MT): For Steel Fasteners

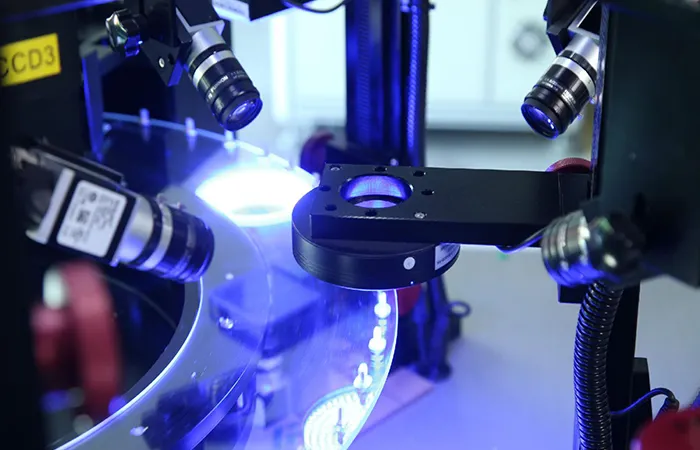

How It Works

-

Magnetize fastener → Crack disrupts magnetic field → Magnetic particles cluster at defect

-

UV light reveals fluorescent particle patterns

Optimal Use Cases

-

Carbon/alloy steel bolts (Grade 5/8, A325)

-

Head-to-shank fillet areas

-

Thread root cracks

JM Hardware® Pro Tip:

*"For high-strength bolts >10.9 grade, use DC magnetization. AC won't detect subsurface flaws."*

2. Liquid Penetrant Testing (PT): Universal Surface Checks

4-Step Process

-

Clean: Remove oil/grease (ASTM E165)

-

Penetrant: Apply red dye/fluorescent fluid (5-30 min dwell)

-

Developer: Draw out penetrant from cracks

-

Inspect: Under white/UV light

Ideal For

-

Stainless steel fasteners (A193 B8)

-

Complex geometries (e.g., socket heads)

-

Field inspections

Limitation Alert: Cannot detect sealed or subsurface defects.

3. Ultrasonic Testing (UT): Deep Defect Detection

Technical Procedure

-

Transducer sends 1-10 MHz sound waves

-

Crack reflection creates echo patterns

-

Time-of-flight calculates depth

Critical Applications

-

Anchor bolts in concrete

-

Large-diameter flange studs

-

Aerospace fasteners (NASM specs)

Data You Get:

✓ Crack depth ✓ Orientation ✓ Length

4. Visual Inspection (VI): First Line of Defense

Enhanced Techniques

| Tool | Magnification | Smallest Detectable Crack |

|---|---|---|

| Naked eye | 1× | 0.5 mm |

| 10x Loupe | 10× | 0.1 mm |

| Digital Microscope | 200× | 5 μm |

Inspection Zones to Target:

-

Under bolt heads

-

Thread run-out sections

-

Stress-corrosion prone areas

Method Selection Guide: Match Technique to Need

Why Trust JM Hardware® Fasteners?

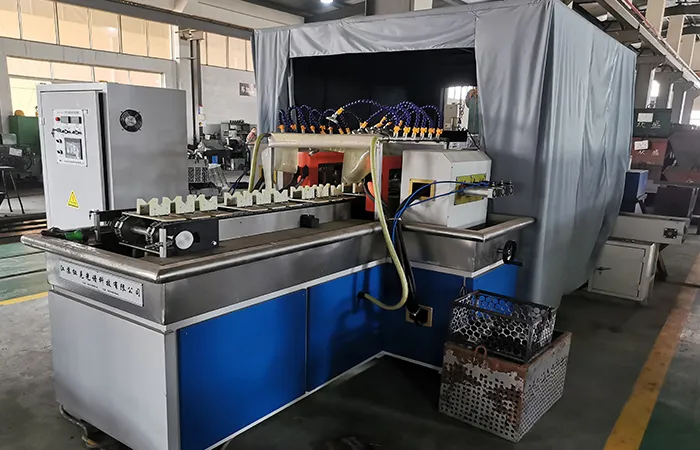

We implement 3-layer quality assurance:

-

Raw Material Scan: PMI (Positive Material Identification)

-

Process Control: Inline UT during cold forging

-

Final Verification: 100% MT for ferromagnetic fasteners

Certifications: ISO 9018, ASTM E1444/E1417, NADCAP AC7114

Request Our Inspection Reports:

✉️ Email: jminfo@jm-industry.com

📱 WhatsApp: +8613681923533 -

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

.jpg?x-oss-process=image/resize,w_100/quality,q_100)